Selection arm neck bush of gear-shifting control assembly and installation structure thereof

A technology of installation structure and inner bushing, which is applied in the direction of components with teeth, transmission device control, bearing components, etc., can solve the problem of excessive play of the handle ball, achieve the elimination of radial play, and solve the problem of handle ball play. The effect of too much gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

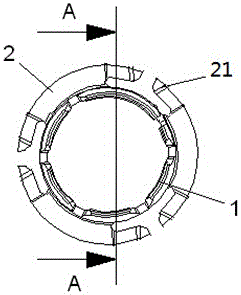

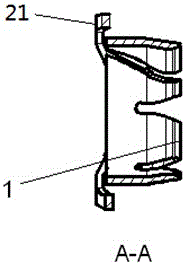

[0022] like Figure 2 to Figure 4 As shown, the selector arm inner bush 3 of the shift control assembly, the sleeve main body 1 of the select arm inner bush 3 is an elastic inner bush with an axial opening, the sleeve main body 1 is used to be sleeved on the shaft pin 4, and is used Press-fitted between the selection arm 5 and the shaft pin 4, the thickness of the sleeve body 1 becomes smaller towards its axial end; the sleeve head 2 of the sleeve 3 in the selection arm extends radially out of the flanging, and the flanging is arranged circumferentially The eight-character lobes 21, the eight-character lobes 21 are composed of a pair of axially warped warps, which are used for press-fitting between the side wall of the selection arm 5 and the fixed retaining ring 7.

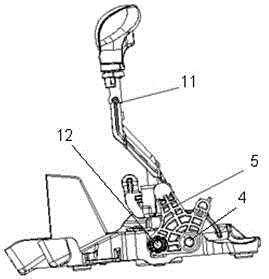

[0023] like Figure 5 Image 6 As shown, the installation structure of the selector arm inner bush of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com