Gap adjusting component and electric lifting adjusting device of automobile seat with gap adjusting component

A technology of clearance adjustment and lifting adjustment, which is applied in electromechanical devices, vehicle seats, movable seats, etc., can solve the problems of many parts and high cost, and achieve the effect of cost reduction, number of parts reduction, and elimination of axial clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

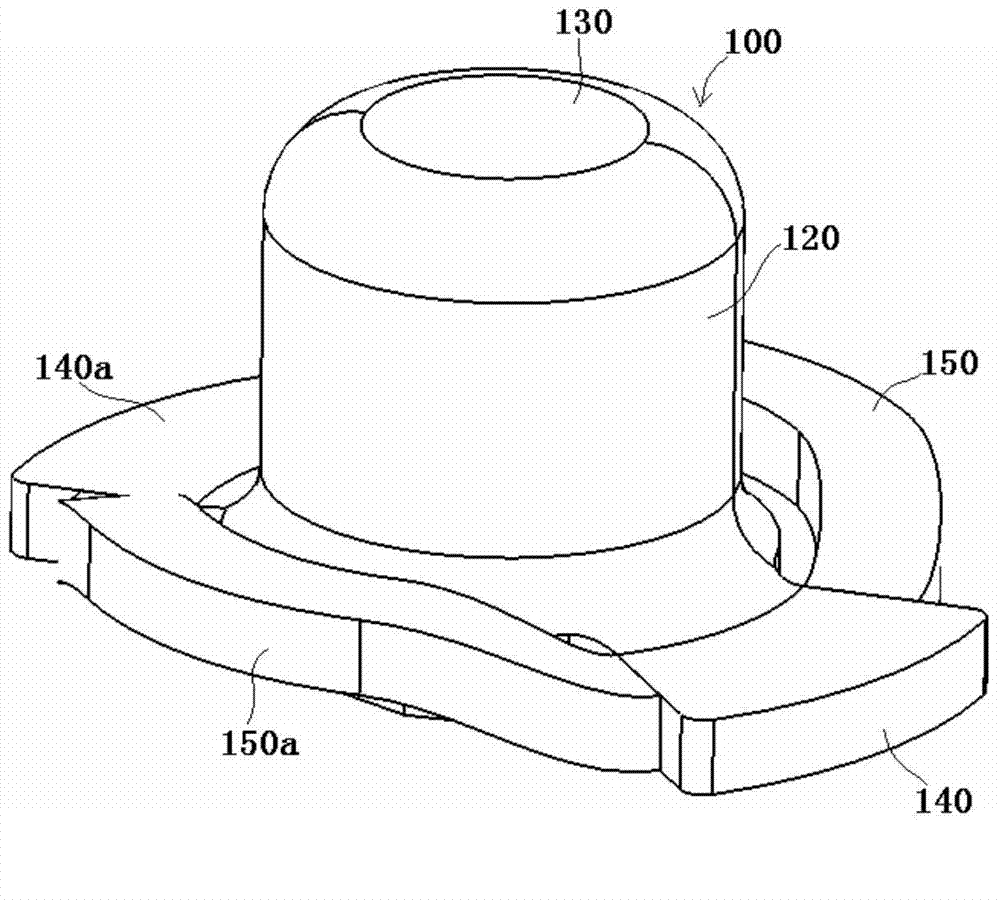

[0041] see image 3 and Figure 4 , the gap adjustment member 100 shown in the figure is a plastic part, which includes a cylinder part 120 with an inner cavity 110, one end of the cylinder part 120 is open, and the other end is provided with an axially restricting end wall 130, in the cylinder The wall of the inner chamber 110 of the body part 120 is provided with a straight exhaust groove 111 parallel to the axis of the barrel part 120 .

[0042] At one end of the cylinder part 120, there are two fan-shaped stoppers 140, 140a symmetrically arranged to limit the rotation of the gap adjustment member 100, and at one end of the cylinder part 120, two axial gap adjustment bellows are also symmetrically arranged. Edges 150, 150a, the two ends of each axial clearance adjusting corrugated edge 150, 150a are respectively connected with two stoppers 140, 140a, and at the same time, the inner edge of each axial clearance adjusting corrugated edge 150, 150a is not in contact with the ...

Embodiment 2

[0045] see Image 6 and Figure 7, the gap adjustment member 100' shown in the figure is a plastic part, which includes a cylinder part 120' with an inner cavity 110', one end of the cylinder part 120' is open, and the other end is provided with an axially restricting end wall 130 ′, an exhaust hole 131 ′ communicating with the inner chamber 110 ′ of the cylindrical portion 120 ′ is opened in the center of the axially restricting end wall 130 ′ of the cylindrical portion 120 ′.

[0046] One end of the cylinder part 120' is symmetrically provided with two fan-shaped stoppers 140', 140a' for restricting the rotation of the gap adjusting member 100', and two symmetrically arranged at one end of the cylinder part 120'. Axial gap adjustment corrugated edges 150', 150a', the two ends of each axial gap adjusting corrugated edge 150', 150a' are respectively connected with two stoppers 140', 140a', and each axial gap adjusting corrugated The inner edges of the sides 150', 150a' are n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com