Electrically powered linear actuator

A linear actuator, electric technology, applied in the direction of transmission, gear transmission, transmission control, etc., can solve the problems of increased power loss, increased electric motor size and energy consumption, etc., to eliminate axial play, The effect of preventing run lock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0039] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

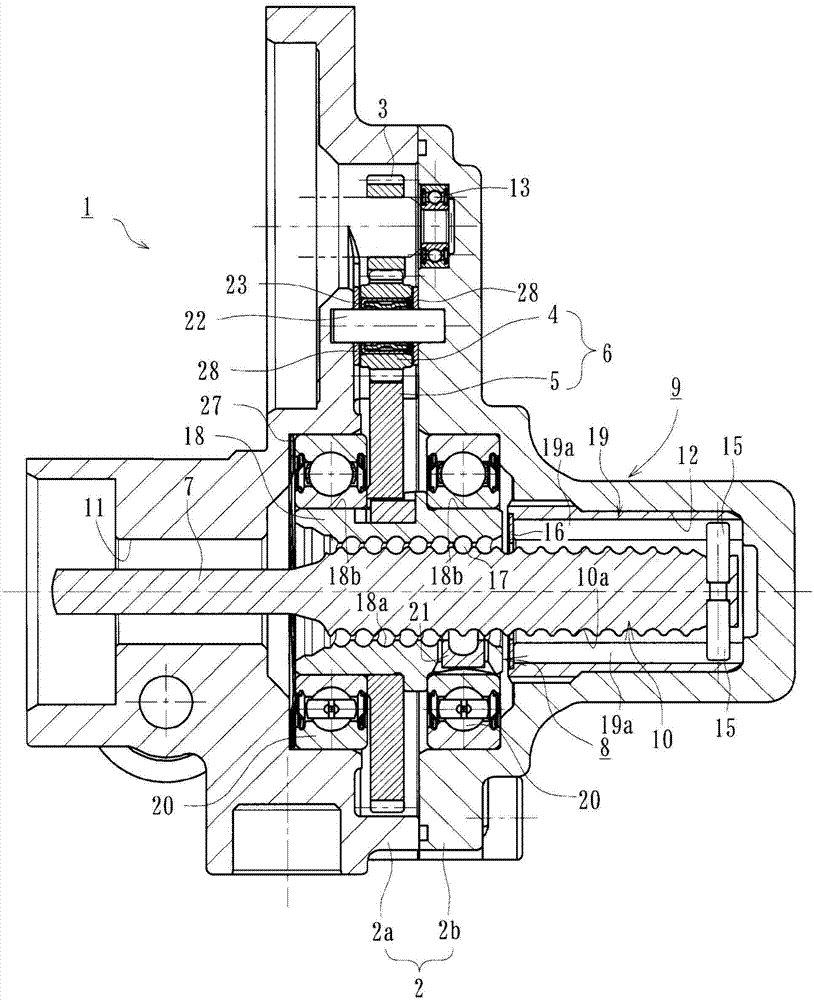

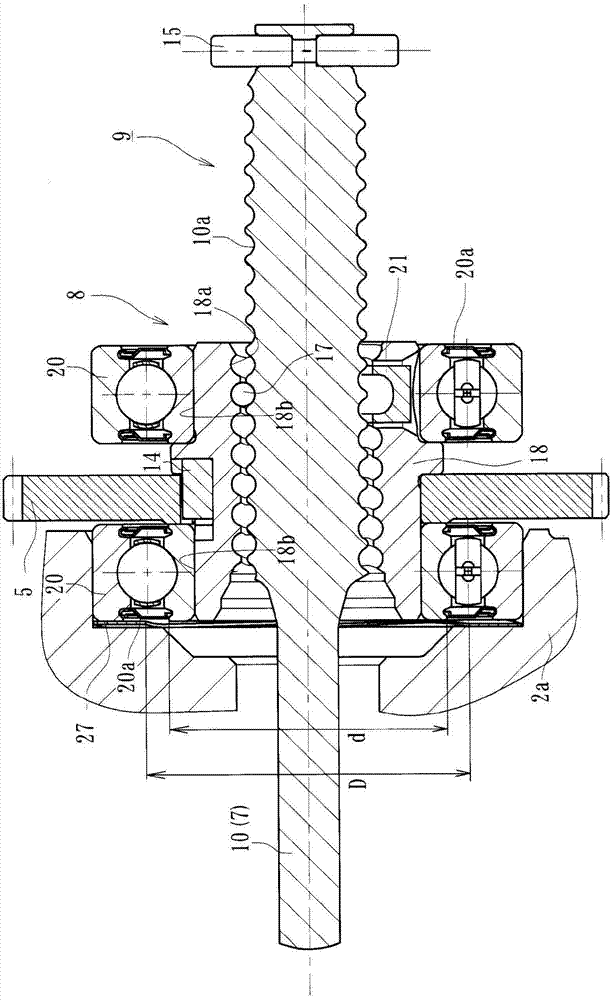

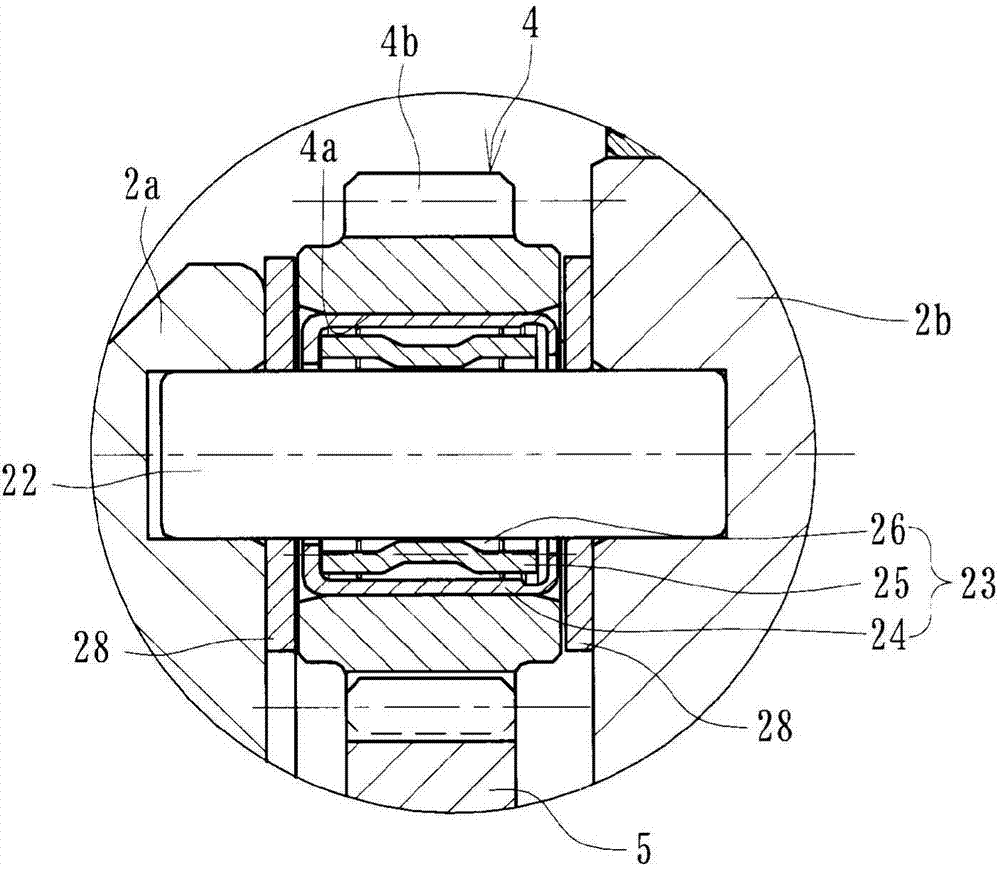

[0040] figure 1 is a longitudinal sectional view showing the first preferred embodiment of the electric linear actuator of the present invention, figure 2 is showing figure 1 Longitudinal sectional view of the actuator body of the electric linear actuator, image 3 is showing figure 1 A partial enlarged view of the intermediate gear of the electric linear actuator, and Figure 4 is showing image 3 A partial enlarged view of a variant of the intermediate gear.

[0041] Such as figure 1 As shown in , the electric linear actuator 1 includes: a casing 2 formed of light aluminum alloy; an electric motor (not shown) mounted on the casing 2; a speed reduction mechanism 6, which includes a The input gear 3 on the motor shaft (not shown) cooperates with the intermediate gear 4 and includes the output gear 5; a ball screw for converting the rot...

no. 2 approach

[0056] Figure 5 is a longitudinal sectional view showing a second preferred embodiment of the electric linear actuator of the present invention. The main difference between this embodiment and the first embodiment is only the structure of the supporting bearing and the washer, therefore, the same reference numerals as used in the first embodiment are also used in this embodiment to denote the same reference numerals as in the first embodiment. Those parts or parts having the same function as those parts or parts.

[0057] The electric linear actuator 31 includes: a housing 2 formed of light aluminum alloy; an electric motor (not shown); an intermediate gear 4 cooperating with an input gear 3 mounted on a motor shaft (not shown) of the electric motor; A reduction mechanism 6, which comprises an intermediate gear 4 and an output gear 5; a ball screw mechanism 8' for converting the rotational motion of the electric motor into an axial linear motion of the drive shaft 7 via the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com