Motor assembly and vehicle starter

A technology of motor components and starters, which is applied in the direction of electric components, motor starters for engines, machines/engines, etc., to achieve the effect of avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Some preferred embodiments of the present application will be described below with reference to the accompanying drawings.

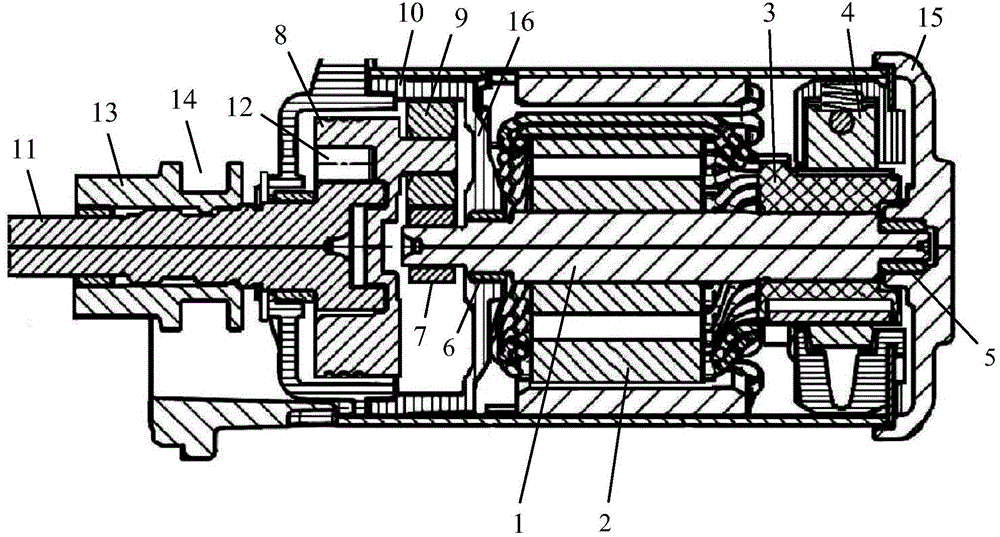

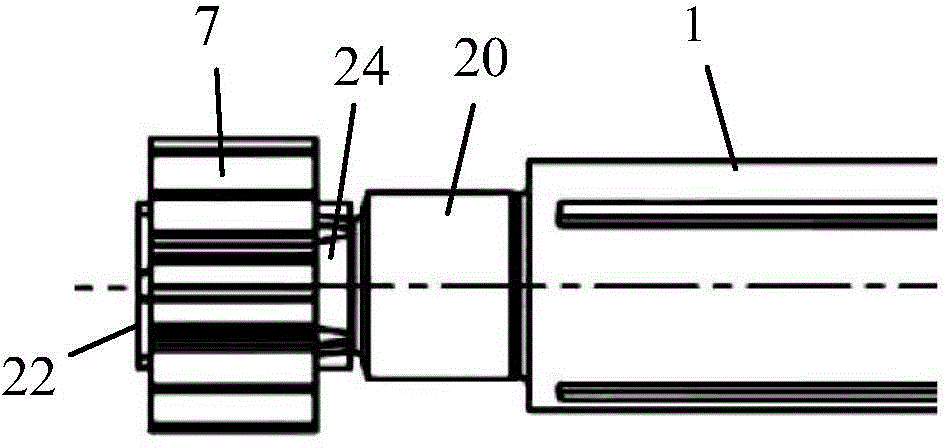

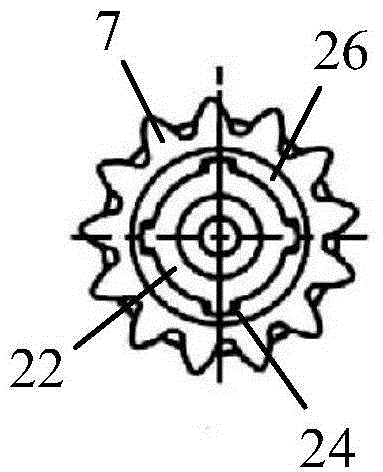

[0025] first, figure 1 A part of the vehicle starter of the present application is shown in , which mainly includes a motor assembly, a transmission mechanism and an electromagnetic switch, wherein the main components of the motor assembly and transmission mechanism are shown, and the electromagnetic switch is not shown.

[0026] The motor assembly is mainly composed of two parts, the motor and the speed change mechanism (reduction mechanism here). The motor mainly includes: an armature shaft 1; an armature winding 2 installed on the armature shaft 1; a commutator (commutator ) 3; push against the carbon brush 4 for power supply on the outer periphery of the commutator 3 .

[0027] The armature shaft 1 is supported at its axial ends by bearings 5, 6, respectively. Specifically, the rear portion of the armature shaft 1 is supported by a bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com