Method for fixed upper bearing of axial parts

A technology of shaft parts and bearings, which is applied in the axial positioning and fixing fields of rolling bearings, can solve the problems of bearing axial movement and affecting product performance, and achieve the effects of eliminating axial clearance, good plasticity and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

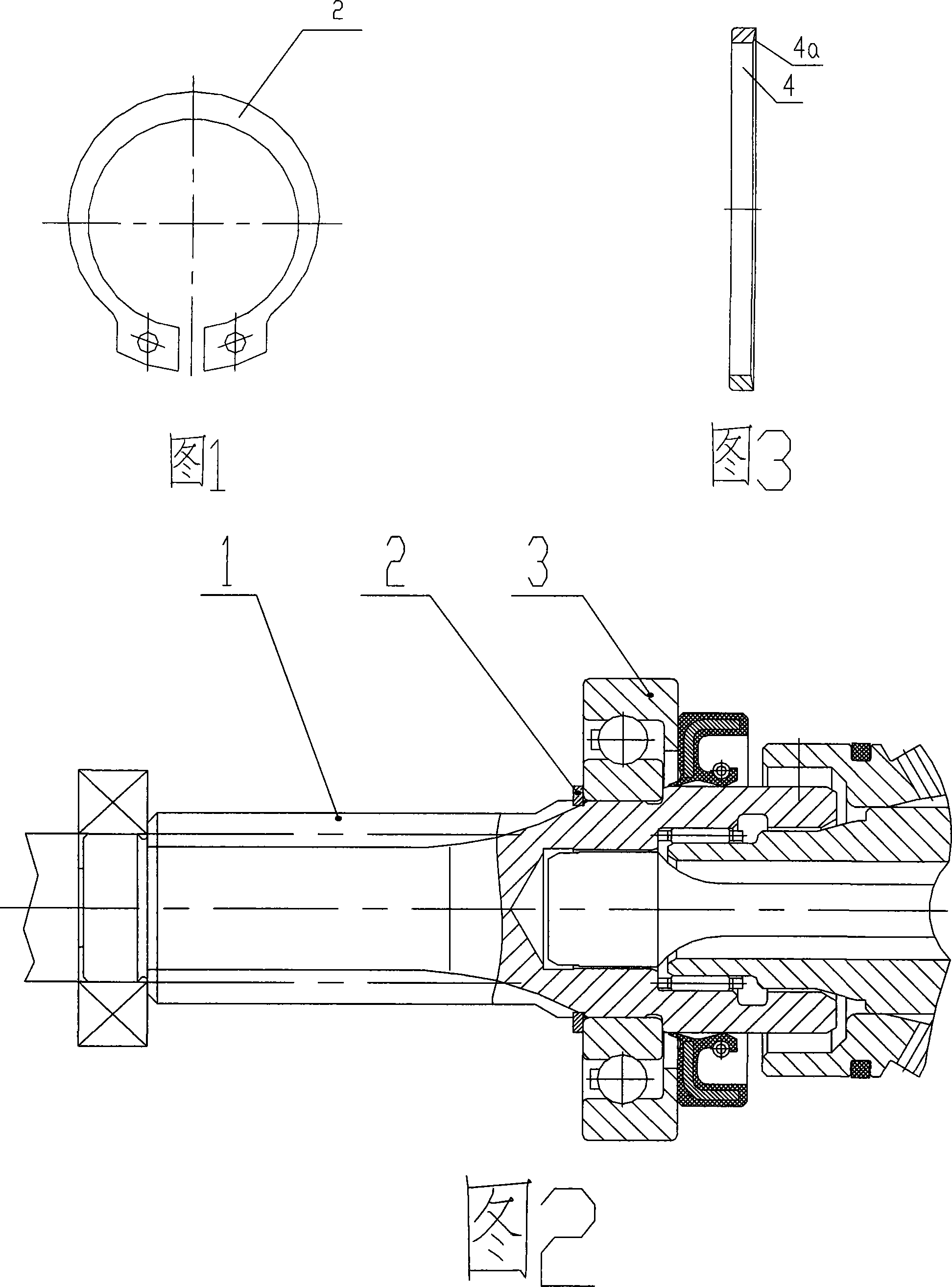

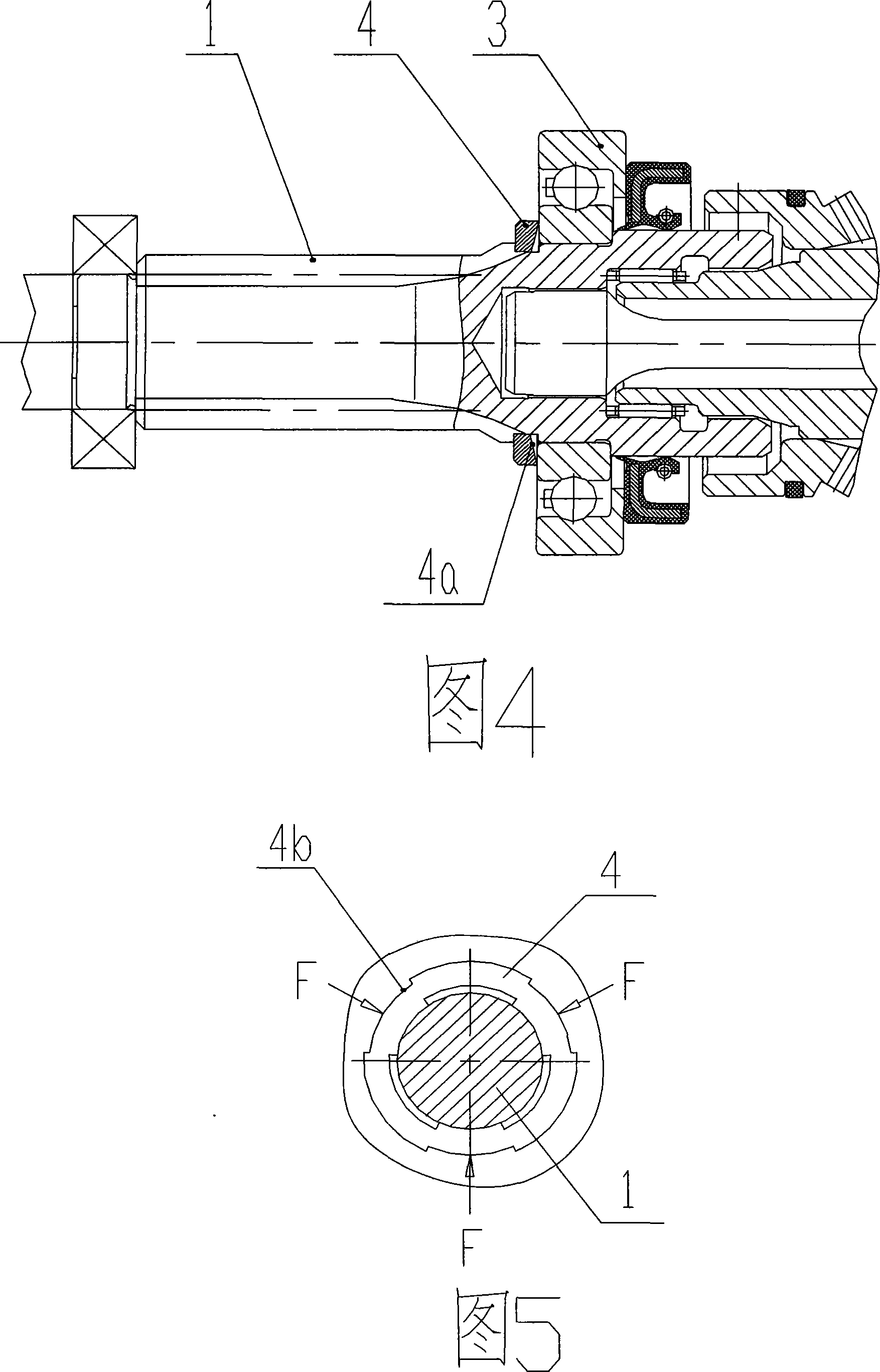

[0014] The present invention will be further described below in conjunction with accompanying drawing example:

[0015] The present invention replaces the current snap-ring type spring steel retaining ring with the retaining ring and its assembly process provided below to realize the axial positioning of the bearing on the shaft parts and finally fix the bearing.

[0016] Referring to Fig. 3, the retaining ring 4 provided by the present invention is a closed-loop body, one end of which is provided with an inner tapered surface 4a, and the material is low carbon steel. For ease of assembly, the inner hole of the retaining ring 4 can be slightly larger than the inner hole of the bearing it is positioned on. In order to meet the requirements of good plasticity, easy deformation and more economical, the material of the retaining ring is best to choose No. 10 or No. 20 low-carbon steel, which is directly cut without heat treatment. The inner tapered surface 4a provided on the reta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com