Transmission device of precise displacement actuator

A transmission device and precision displacement technology, which is applied to transmission devices, transmission parts, belts/chains/gears, etc., can solve the problems of easy wear of threaded transmission pairs, excessive clearance of axial backlash, and difficult grinding of internal threads, etc. problems, achieve the effect of reducing precision machining requirements, eliminating axial clearance, and satisfying driving and positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

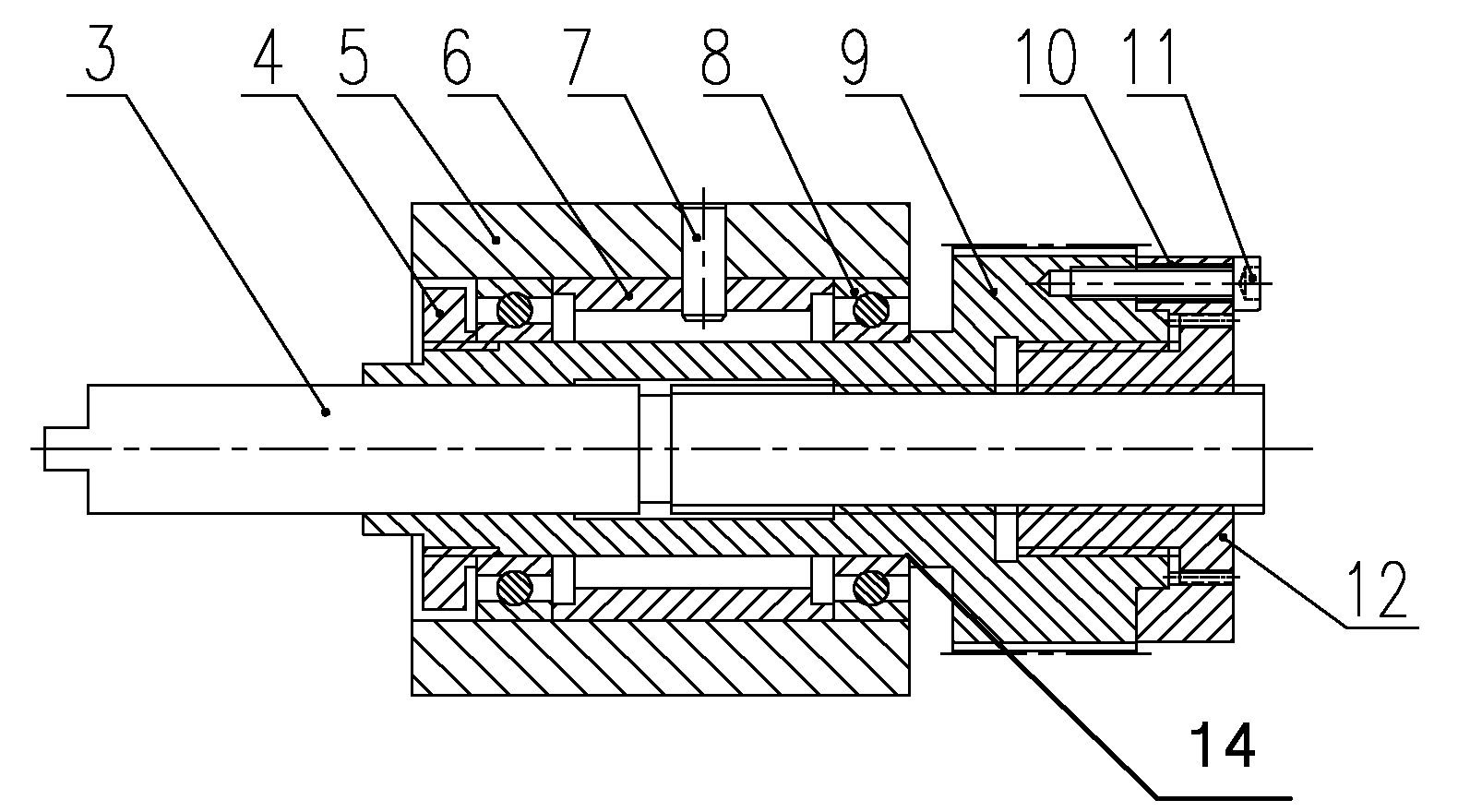

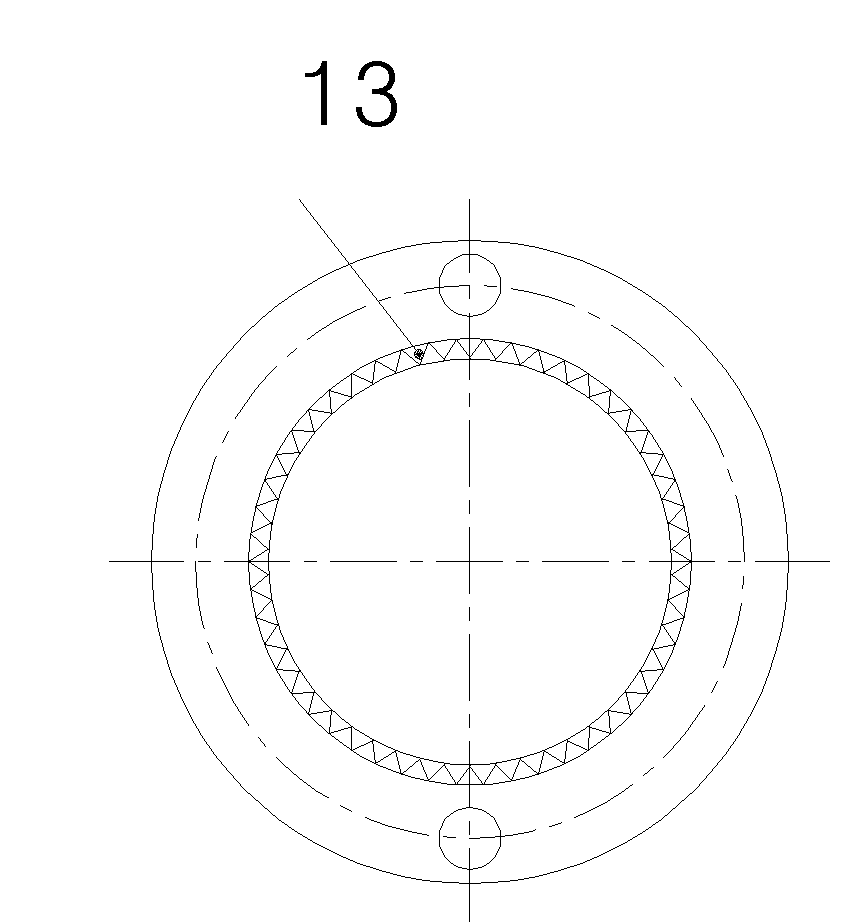

[0018] refer to figure 2 , a precision displacement actuator transmission, consisting of a rotating nut and a screw 3 transmission pair, the rotating nut adopts a double-nut structure, one of which is a main body nut 9, and the other is an anti-backlash nut 12; the anti-backlash nut 12 is provided with The internal and external threads have different pitches. The anti-backlash nut 12 is embedded in the front end of the main body nut 9, and is connected to the screw rod 3 through the internal thread, and is connected to the main body nut 9 through the external thread. Such as image 3 and Figure 4 As shown, the flange at the end of the anti-backlash nut is provided with a fixed ring 10, and the inner circle of the fixed ring 10 and the outer circle of the anti-backlash nut 12 are provided with 13 toothed grooves, and the anti-backlash nut 12 passes through the fixed ring. 10 is fixed on the body nut 9 by screws 11.

[0019] The main body nut 9 is supported in the support h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com