Device for sharpening chain saw teeth

A technology for sharpening and chain saw, which is applied in the field of devices for sharpening chain saw teeth, and can solve the problems of disadvantageous power consumption and inability to compensate for the convexity of the surface to be sharpened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

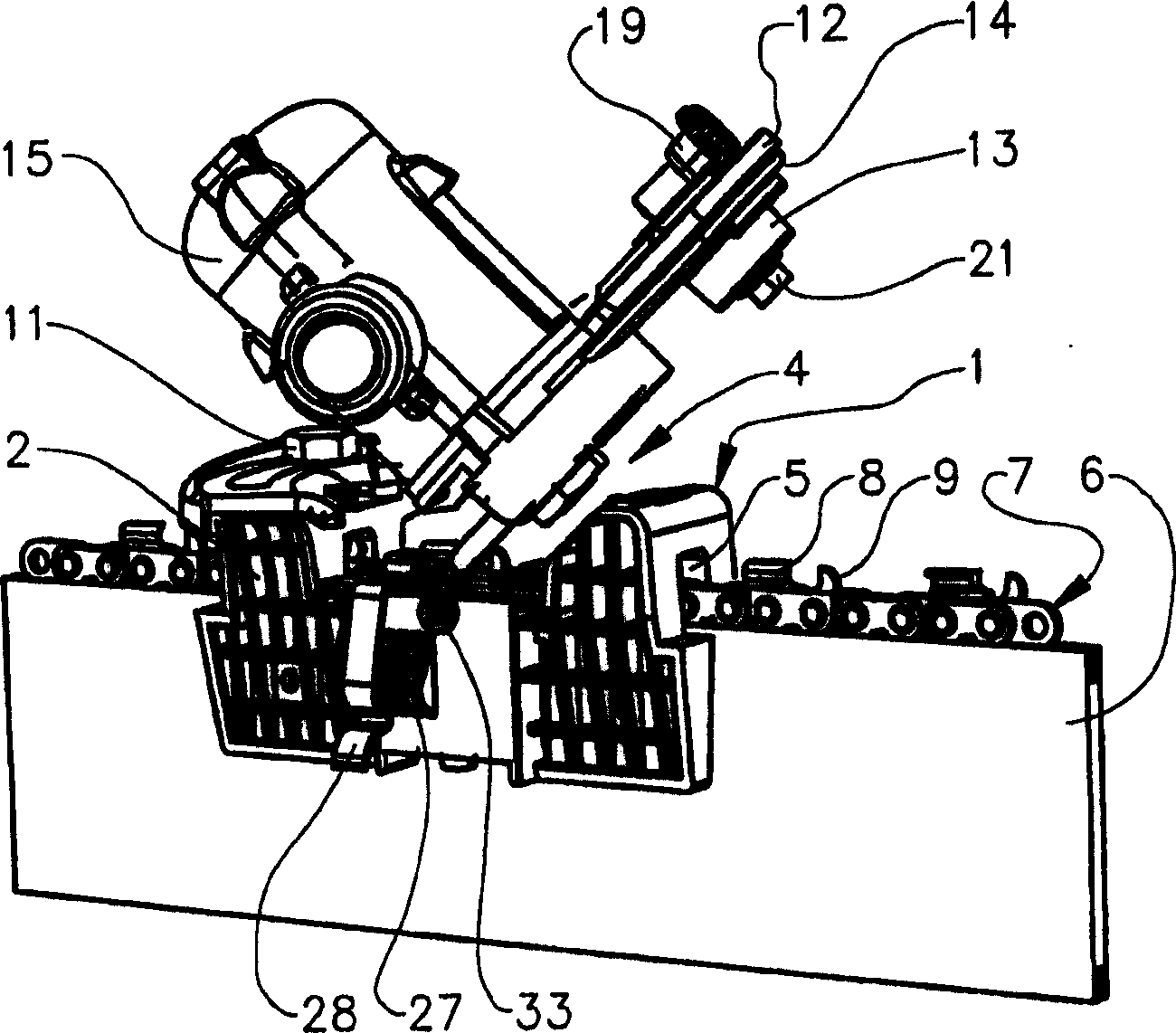

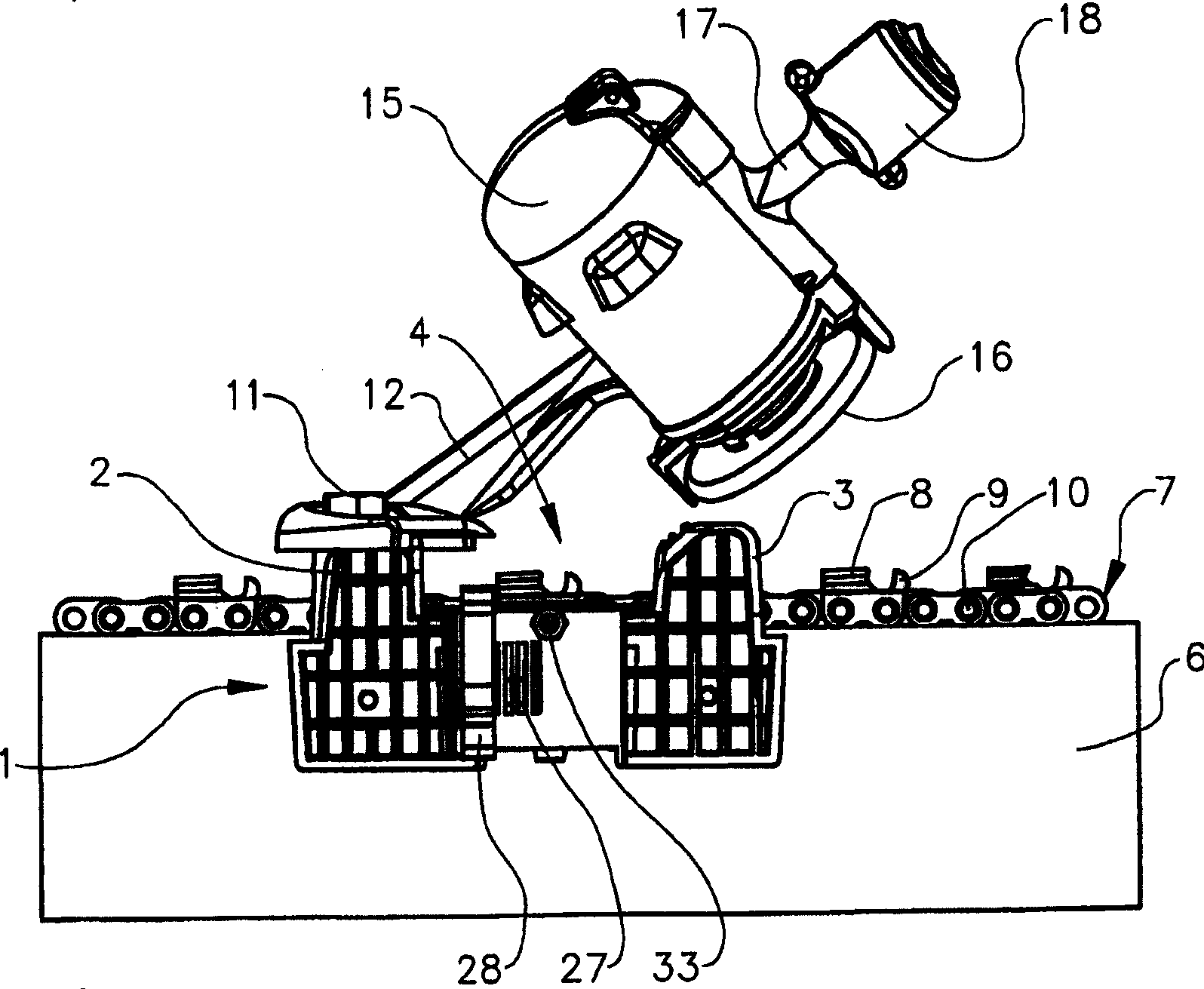

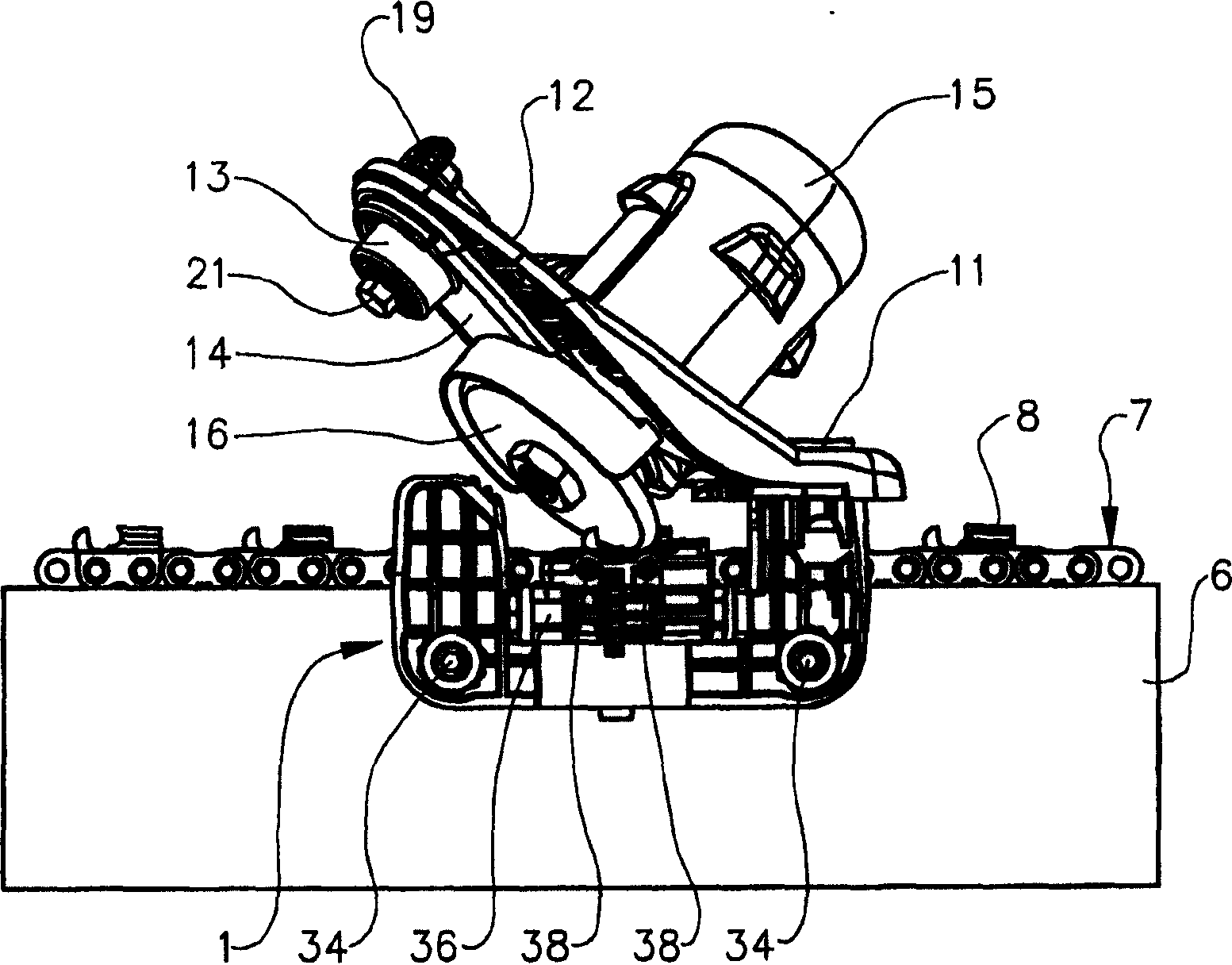

[0018] The device according to the invention comprises a body 1, starting from its first side (in the given case from the upper side) two arms 2, 3 formed on each longitudinal end of said body, a gap 4 being arranged in said between the arms. The body 1 is formed with a groove 5 from its second side (in a given case from the bottom) such that the body 1 resembles the shape of an inverted letter U in the transverse direction. Said groove 5 runs through the body 1 in the region between the two arms 2, 3 so that it is connected to the gap 4 and serves to accommodate the saw blade 6 of the pulling chain 7 consisting of the teeth 8 and the Said teeth are constituted by links of an integral guide member 9 , each said link being connected to the chain 7 by means of a pair of pins 10 .

[0019] A spatially curved bracket 12 is secured to the free end, ie the upper end of the aforementioned arm, by fastening means 11 so that the bracket can be selectively moved along an arc and the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com