Planetary transmission structure of wind power gear box

A wind power gearbox and planetary transmission technology, which is applied to gear transmissions, transmissions, transmission parts, etc., can solve the problems of reduced reliability, inconvenient assembly, disassembly and repair of planetary gears, and achieve load impact prevention and easy assembly and dismantling and repairing, and the effect of meeting the work requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

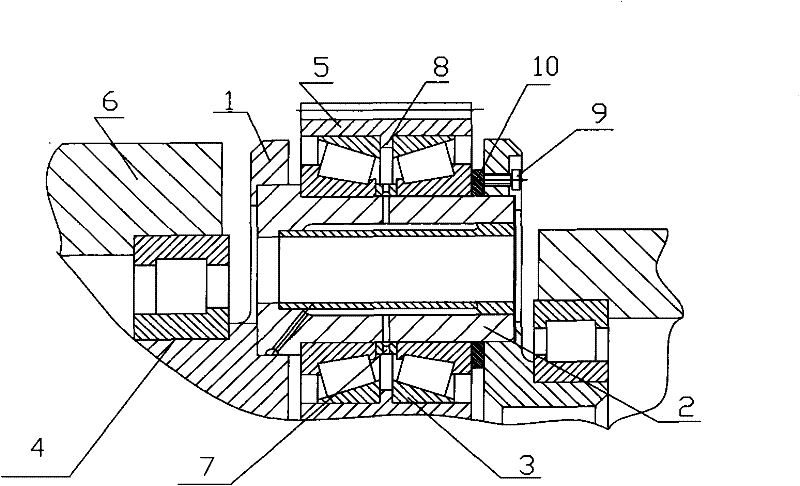

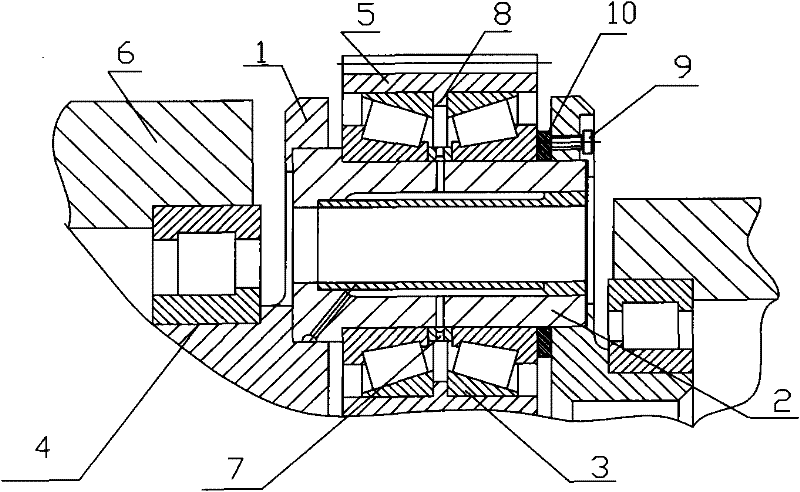

[0009] Such as figure 1 As shown, the planetary transmission structure of the wind power gearbox includes a sun gear, a planetary carrier 1, a spindle 2, a planetary wheel bearing 3, a planetary carrier bearing 4 and a planetary wheel 5, and the planetary carrier 1 is installed on the box body 6 through the planetary carrier bearing 4 , the planetary wheel 5 is installed on the mandrel 2 through the planetary wheel bearing 3, the planetary wheel bearing 3 is a pair of tapered roller bearings and installed back to back, the middle of the inner ring of the tapered roller bearing is provided with an annular washer 7, and the middle of the outer ring It is an inward protrusion 8 on the planetary wheel. The inner ring on one side of the pair of tapered roller bearings is close to the step set on the spindle, and the inner ring on the other side is close to the step set on the planet carrier. The screw 9 is positioned on the washer 10 . The planet carrier 1 is a split structure, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com