Process for indirectly producing alcohol with synthetic gas and application of process

A technology for synthesis gas and methanol synthesis, which is applied in the production of bulk chemicals, preparation of organic compounds, preparation of hydroxyl compounds, etc., and can solve the problems of high material requirements, high price, and economical efficiency to be verified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

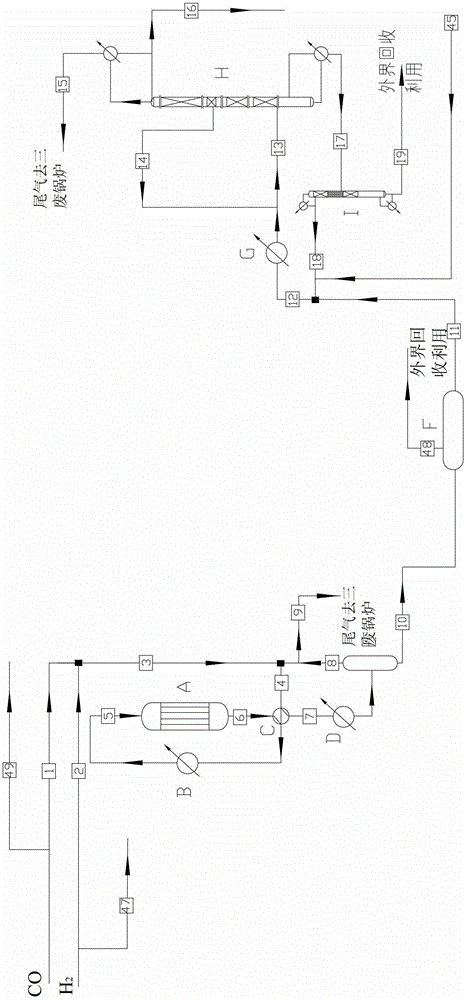

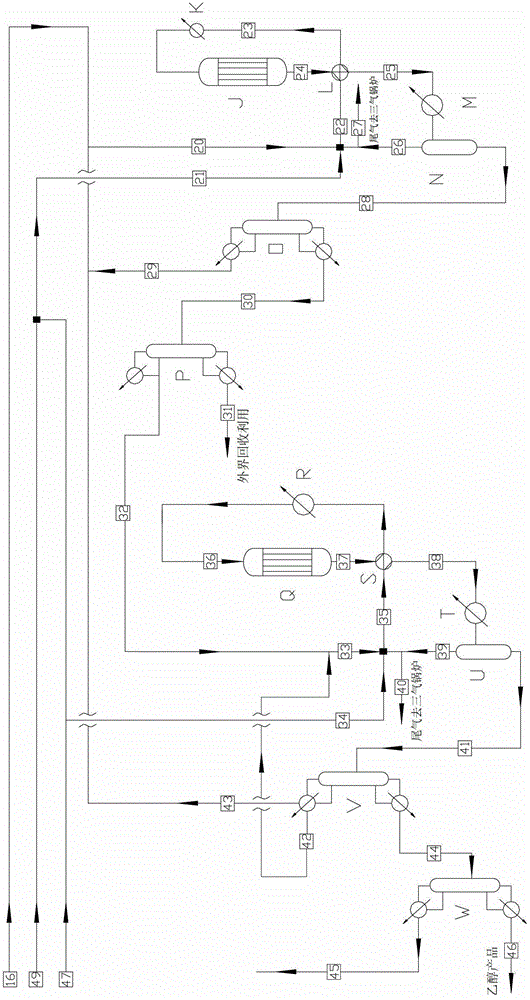

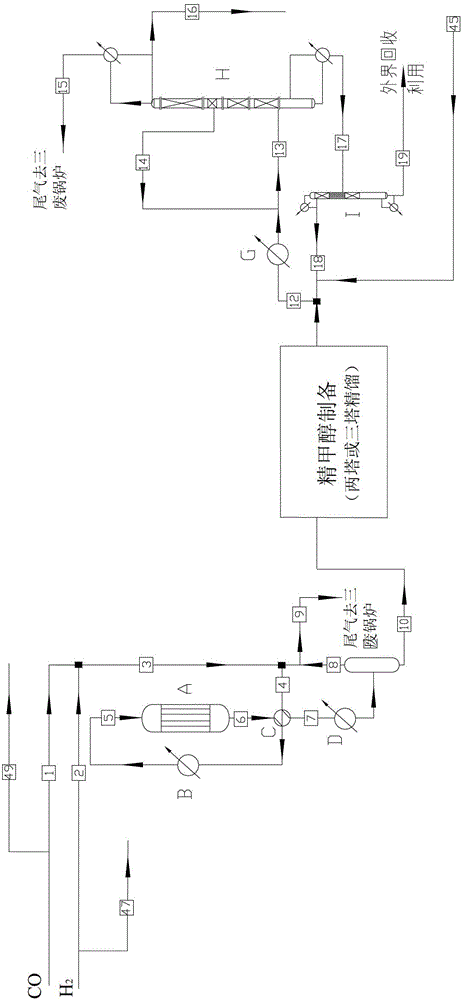

[0097] In this embodiment, refer to the attached Figure 1-2 The device and process shown are equipped with various reaction components.

[0098] Methanol Reactor A is a plate-type fixed-bed reactor with an inner diameter of 40mm and a height of 1800mm. It contains a Cu-Zn-Al methanol synthesis catalyst (composition of CuO 15wt%, ZnO 65wt% and Al 2 O 3 20wt%); The temperature of the reaction zone is 225~265℃, and the reaction pressure is 5MPa;

[0099] Industrial carbon monoxide (98V% purity) and H 2 (Purity is 99.9V%) The synthesis gas is mixed at a volume ratio of 2.7:1, through the methanol reactor outlet heat exchanger C and methanol reactor inlet heat exchanger B, continuously heat exchange to reach the catalyst bed inlet temperature of methanol reactor A After 195°C, the top feed of methanol reactor A is used for catalytic synthesis of methanol. The bottom reaction product is passed through the methanol reactor outlet heat exchanger C for heat exchange with the synthesis gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com