Solar cell module and interconnecting strips thereof

A technology for solar cell modules and interconnecting strips, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of increasing fragmentation and cracking of crystalline silicon solar cells, cracking of solar cells, etc., and reduce volume resistance. The effect of reducing the rate of battery fragmentation and increasing the light-receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: A solar cell module and its interconnection bar

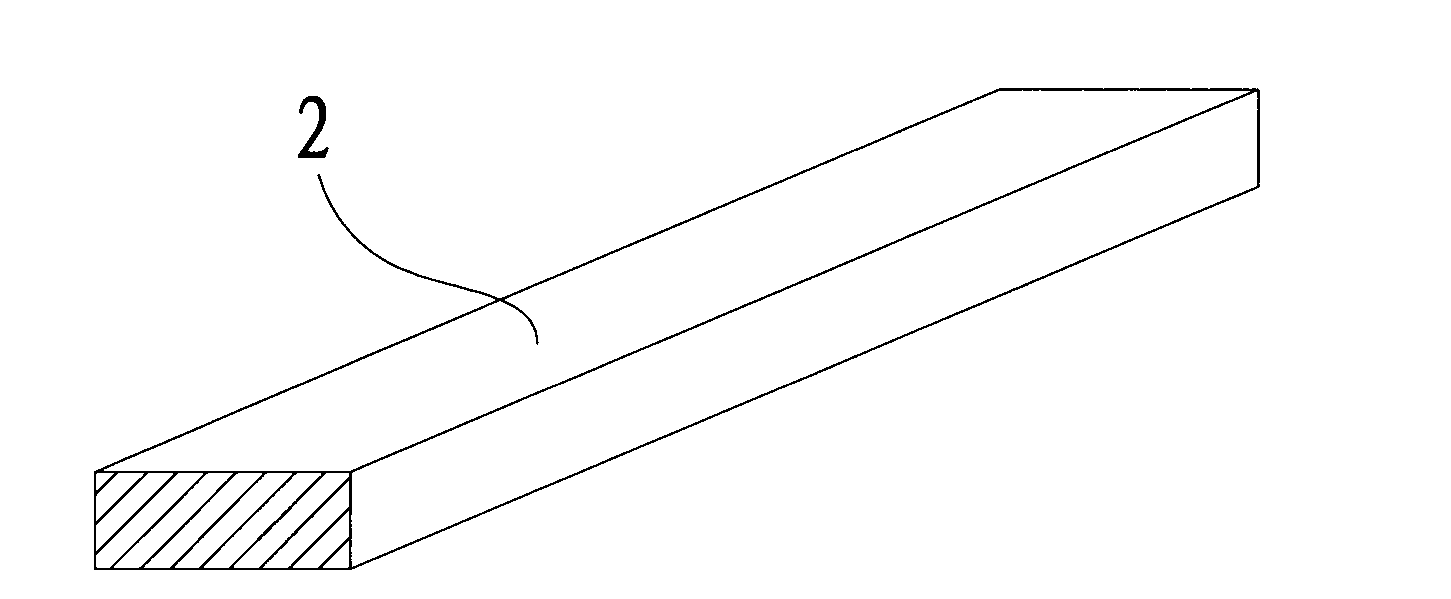

[0019] See attached figure 1 As shown, an interconnection bar 2 has a rectangular cross section, the width of the interconnection bar 2 is 1.0mm, and the thickness is 0.20mm. The interconnection bar 2 is made of pure silver. The volume resistivity of the interconnection bar 2 is 1.5Ω·mm 2 / m; the yield strength of the interconnecting strip 2 is 45 MPa, and the tensile strength is 130 MPa; the elongation of the interconnecting strip 2 is 15%.

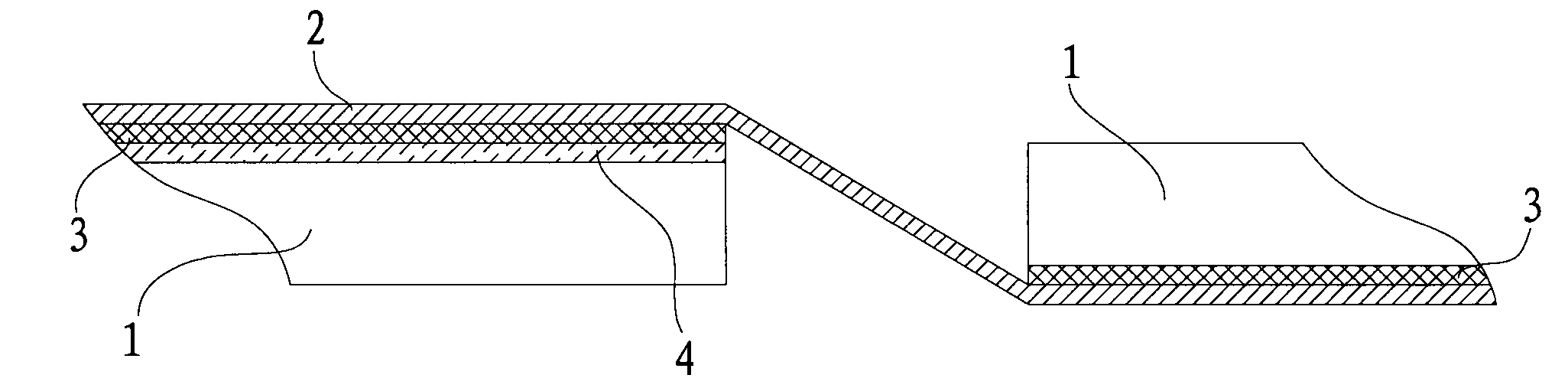

[0020] See attached figure 2 As shown, a solar cell assembly (not shown in the figure), the solar cell assembly includes 60 crystalline silicon solar cells 1, each solar cell 1 has a busbar 4, and the busbar 4 is set There is a conductive adhesive film 3, which is bonded with an interconnection strip 2; the interconnection strip 2 refers to the attached figure 1 As shown, its cross section is rectangular, and the interconnection bar 2 has a width of 1.0 mm and a...

Embodiment 2

[0022] Embodiment 2: A solar cell module and its interconnection bar

[0023] See attached figure 1 As shown, an interconnection strip 2 has a rectangular cross section, the width of the interconnection strip 2 is 0.8mm, and the thickness is 0.35mm. The interconnection bar 2 is made of pure copper. The volume resistivity of the interconnection bar 2 is 1.8Ω·mm 2 / m; the yield strength of the interconnecting strip 2 is 70 MPa, and the tensile strength is 145 MPa; the elongation of the interconnecting strip 2 is 15%.

[0024] See attached figure 2 As shown, a solar cell assembly (not shown in the figure), the solar cell assembly includes 72 crystalline silicon solar cells 1, each solar cell 1 has a busbar 4, and the busbar 4 is set There is a conductive adhesive film 3, which is bonded with an interconnection strip 2; the interconnection strip 2 refers to the attached figure 1 As shown, its cross section is rectangular, and the interconnection strip 2 has a width of 0.8mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com