Graphene solar HJT battery positive silver paste and preparation method thereof

A technology of graphene and solar energy, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as long time, poor adhesion between grid lines and silicon wafers, and affecting production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

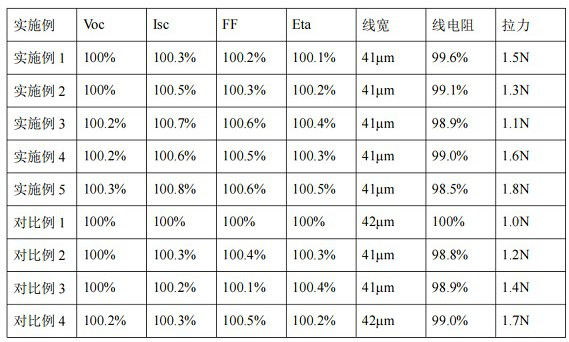

Examples

Embodiment 1

[0033] S1: Set the temperature of the resin and solvent to 95°C, stir and mix until clear and transparent, and control the viscosity to 30Kcps to obtain an organic vehicle;

[0034] S2: Mix 10% nano-silver powder, 81.5% flake silver powder, 7.5% organic vehicle, 0.5% organic additives, and 0.5% graphene; place it in a planetary mixer, set the speed at 30~35rpm, and the temperature at 25°C Stir for 30 minutes; place in a three-roll mill, grind and disperse until the fineness is less than 6 μm, adjust the viscosity, and obtain a front silver paste with a viscosity of 400Kcps.

[0035] In this technical scheme, the particle diameter D50 of the nano-silver powder is 160nm, and the specific surface area is 18m 2 / g; the particle size D50 of the flake silver powder is 5 μm, and the specific surface area is 6m 2 / g; The monolayer thickness of described graphene is 15nm, and particle diameter D50 is 1.0 μm, and specific surface area is 15m 2 / g, the resistivity is less than 10 -7 ...

Embodiment 2

[0037] S1: Set the temperature of the resin and solvent to 100°C, stir and mix until clear and transparent, and control the viscosity to 28Kcps to obtain an organic vehicle;

[0038] S2: Mix 9.5g nanometer silver powder, 82g flake silver powder, 7.5g organic carrier, 0.5g organic additive, and 0.5g graphene; place in a planetary mixer, set the speed at 35rpm, and stir at 25°C for 30min; Place in a three-roll mill, grind and disperse to a fineness of less than 6 μm, adjust the viscosity, and obtain a front silver paste with a viscosity of 400Kcps.

[0039] In this technical scheme, the particle diameter D50 of the nano-silver powder is 160nm, and the specific surface area is 18m 2 / g; the particle size D50 of the flake silver powder is 5 μm, and the specific surface area is 6m 2 / g; The monolayer thickness of described graphene is 15nm, and particle diameter D50 is 1.0 μm, and specific surface area is 15m 2 / g, the resistivity is less than 10 -7 Ω·m; the resin is bisphenol ...

Embodiment 3

[0041] S1: Set the temperature of the resin and solvent to 90°C, stir and mix until clear and transparent, and obtain an organic vehicle with a viscosity of 35Kcps;

[0042] S2: (1) Weigh and mix dopamine and polyethylene glycol-poly(4-sodium styrene sulfonate) copolymer according to the mass ratio of 1:0.85, and then dissolve them in Tris buffer to obtain a concentration of 0.1g / Mixed solution A of L; immerse the nano-silver powder A in the mixed solution A at 25°C and ultrasonically disperse it, and stir for 20 hours to obtain the nano-silver powder A; (2) The volume ratio of polyvinylpyrrolidone, dopamine solution, and Tris buffer is 10:1:1, disperse graphene in 4g / L polyvinylpyrrolidine copper solution, stir for 12 hours; add 0.5g / mL dopamine solution, stir for 2 hours; add Tris buffer, stir for 20 hours to get Graphene A; (3) Premix nano-silver powder A with flaky silver powder, add organic carrier and organic additives and mix evenly, add graphene A and mix evenly, plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com