Dye-sensitized solar cell counter electrode and production method thereof

A technology of solar cells and dye sensitization, applied in the field of solar cells, can solve problems such as poor electronic capabilities, and achieve the effects of good stability, simple operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

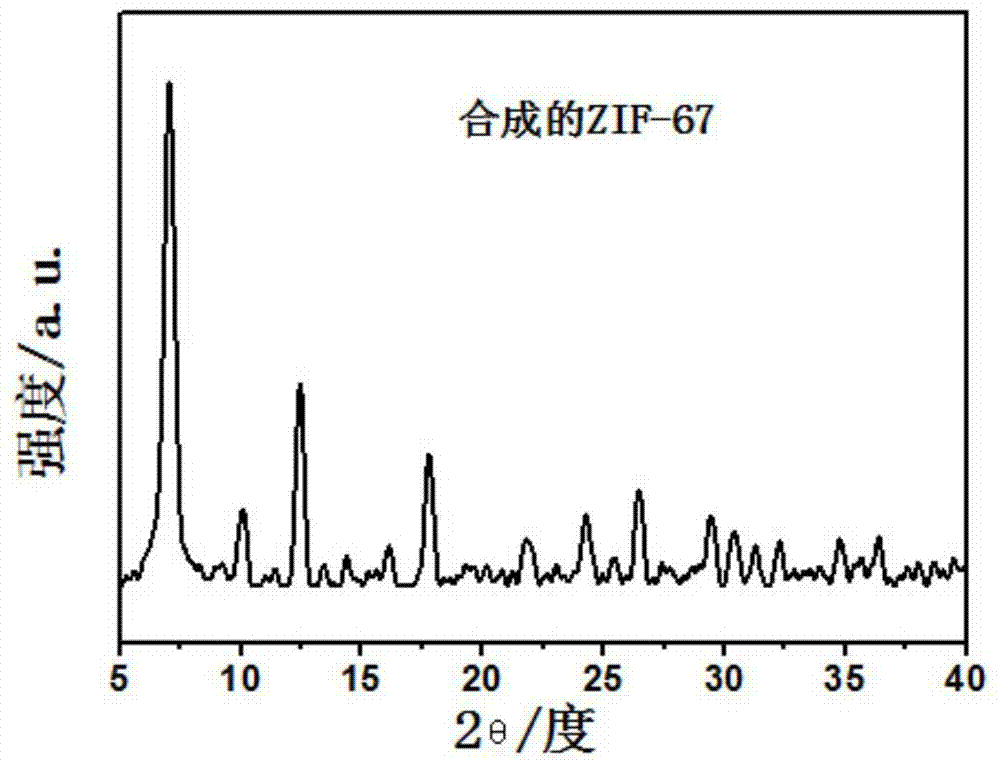

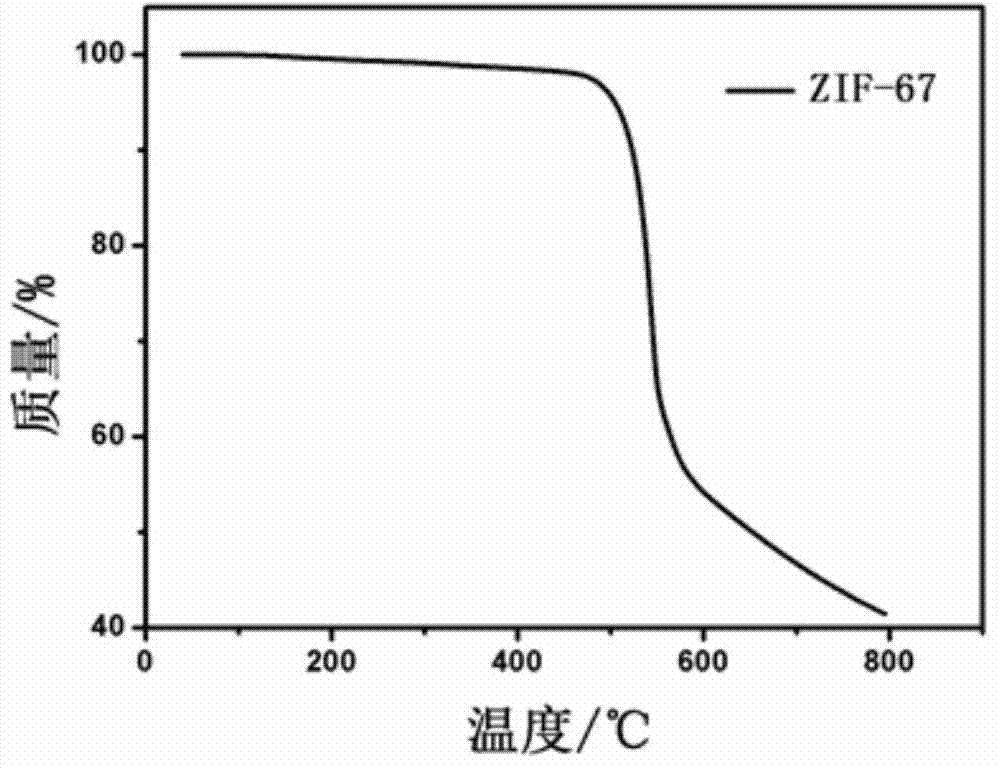

[0030] (1) Dissolve 1.3122g 2-methylimidazole in 30ml methanol respectively, 1.1641g Co(NO 3 ) 2 ·6H 2 O was dissolved in 30ml of methanol, where Co(NO 3 ) 2 ·6H 2 The molar ratio of O to 2-methylimidazole is 1:4. After stirring for about 30 minutes at room temperature, the two solutions are uniformly mixed, then stirred for about 30 minutes, centrifuged, and the obtained product is washed 2 to 3 times by centrifugal method with absolute ethanol. Then vacuum-dry at 40°C for about 12 hours to obtain purple powder ZIF-67 (the characterization diagram of ZIF-67 is shown in the attached figure 1 and figure 2 shown);

[0031] (2) Put the synthesized purple powder ZIF-67 into a tube furnace and roast at 650°C for 2h under nitrogen atmosphere, and then drop to room temperature;

[0032] (3) Dissolve the product obtained in step (2) in isopropanol (analytically pure, the dosage is 4ml of isopropanol for every 200 mg of product), ball mill for about 6-8 hours, and spray on the...

Embodiment 2

[0034] The conditions and steps are the same as in Example 1, except that the calcination temperature in step (2) is 750°C.

Embodiment 3

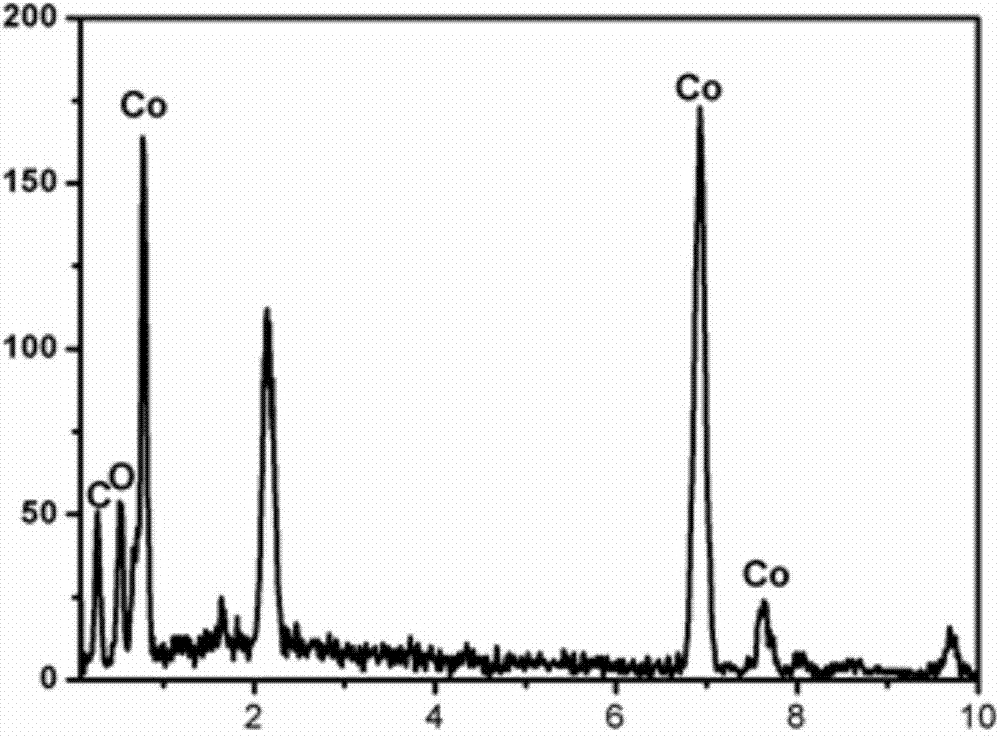

[0036] The conditions and steps are the same as in Example 1, except that the calcination temperature in step (2) is 850°C. Wherein, the energy spectrum of the product obtained in step (2) is as attached image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com