Anti-reflection high-transmittance coated solar super-white embossed glass and manufacturing method thereof

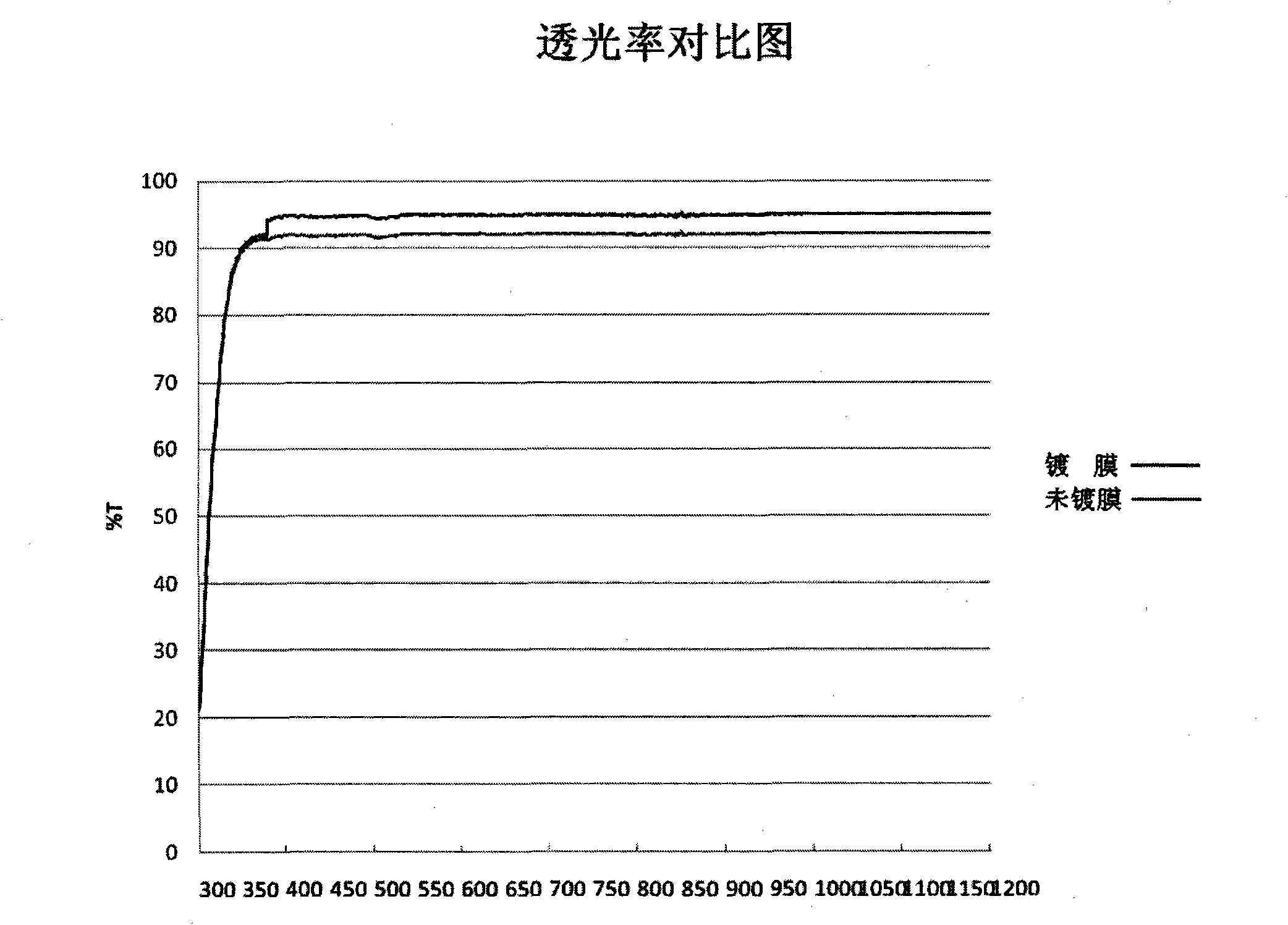

A technology of ultra-clear embossed glass and high transmittance, which is applied in the field of ultra-clear embossed glass, which can solve the problems of affecting the power of solar power generation components and low effective light transmittance, reduce thermal effects, improve glass whiteness, The effect of high solar transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] An antireflection and high transmittance coated solar ultra-clear embossed glass, the composition of the weight percentage of each component of the glass base layer is:

[0058]SiO 2 72.50%

[0059] Al 2 o 3 2.50%

[0060] Fe 2 o 3 0.01%

[0061] CaO 11.00%

[0062] R 2 O 13.50%

[0063] Sb 2 o 3 0.39%

[0064] CeO 2 0.10%

[0065] The formation process of the coating layer on the glass substrate is as follows:

[0066] (1) Preparation of coating nanomaterials;

[0067] Form the weight percent of each component of coating film layer is:

[0068] {(CH 3 ) 2 CHOH} 68%;

[0069] (H 2 O) 7%;

[0070] (C 2 h 6 o 2 ) 10%;

[0071] SiO 2 15%

[0072] with SiO 2 As a precursor, the temperature and time of the alcohol reduction process control the reduction reaction cooling and reflux speed to obtain the porous nanomaterial SiO that needs to survive 2 ; After the colloid is obtained, it is diluted with alcohol to c...

Embodiment 2

[0077] An antireflection and high transmittance coated solar ultra-clear embossed glass, the composition of the weight percentage of each component of the glass base layer is:

[0078] SiO 2 73.50%

[0079] Al 2 o 3 0.50%

[0080] Fe 2 o 3 0.006%

[0081] CaO 8.00%

[0082] MgO 4.00%

[0083] R 2 O 13.50%

[0084] Sb 2 o 3 0.10%

[0085] CeO 2 0.394%

[0086] The formation process of the coating layer on the glass substrate is as follows:

[0087] (1) Preparation of coating nanomaterials;

[0088] Form the weight percent of each component of coating film layer is:

[0089] {(CH 3 ) 2 CHOH} 77%;

[0090] (H 2 O) 5%;

[0091] (C 2 h 6 o 2 ) 8%;

[0092] SiO 2 10%

[0093] with SiO 2 As a precursor, the temperature and time of the alcohol reduction process control the reduction reaction cooling and reflux speed to obtain the porous nanomaterial SiO that needs to survive 2 ; After the colloid is obtained, it is...

Embodiment 3

[0098] An antireflection and high transmittance coated solar ultra-clear embossed glass, the composition of the weight percentage of each component of the glass base layer is:

[0099] SiO 2 74.00%

[0100] Al 2 o 3 0.50%

[0101] Fe 2 o 3 0.006%

[0102] CaO 10.194%

[0103] R 2 O 14.50%

[0104] Sb 2 o 3 0.40%

[0105] CeO 2 0.40%

[0106] The formation process of the coating layer on the glass substrate is as follows:

[0107] (1) Preparation of coating nanomaterials;

[0108] Form the weight percent of each component of coating film layer is:

[0109] {(CH 3 ) 2 CHOH} 70%;

[0110] (H 2 O) 6%;

[0111] (C 2 h 6 o 2 ) 9%;

[0112] SiO 2 15%

[0113] with SiO 2 As a precursor, the temperature and time of the alcohol reduction process control the reduction reaction cooling and reflux speed to obtain the porous nanomaterial SiO that needs to survive 2 ; After the colloid is obtained, it is diluted with alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com