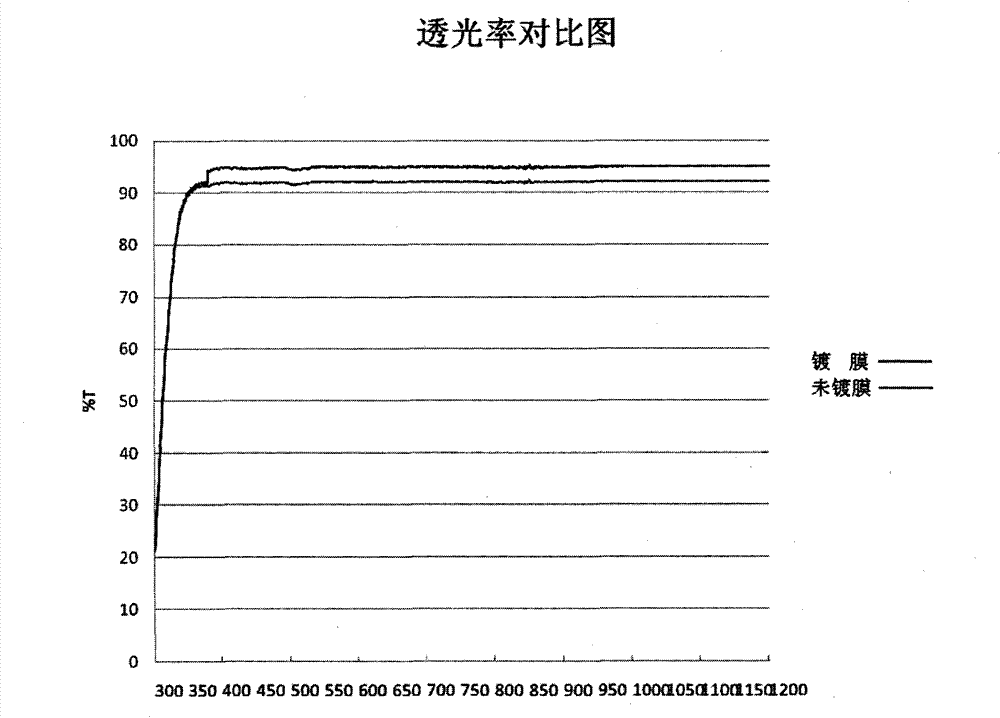

Anti-reflection high-transmittance coated solar super-white embossed glass and manufacturing method thereof

A technology of ultra-clear embossed glass and high transmittance, applied in the field of ultra-clear embossed glass, can solve the problems of low effective light transmittance, affecting the power of solar power generation components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

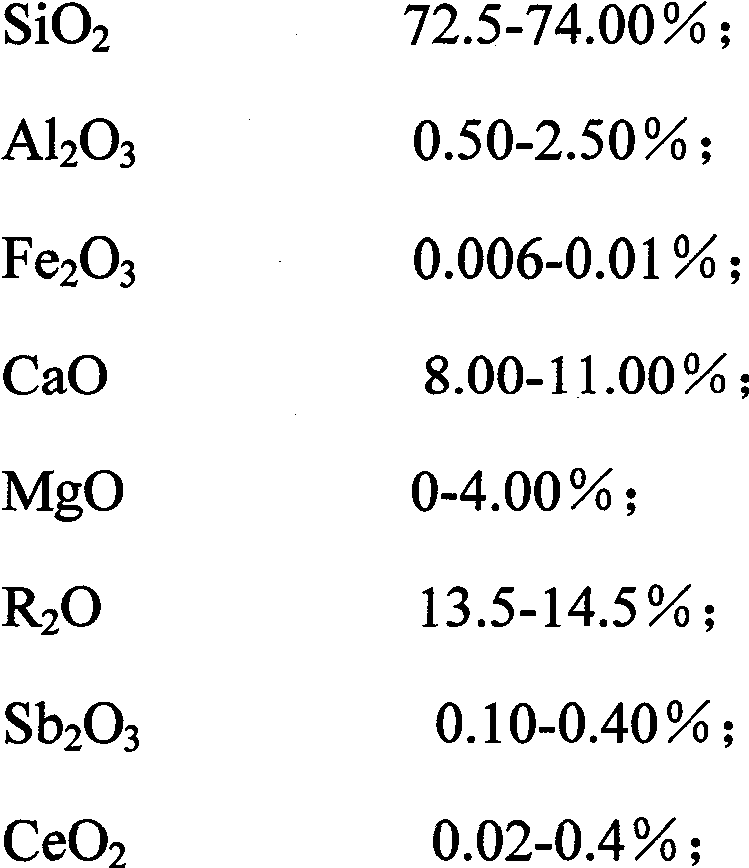

[0058] An antireflection and high transmittance coated solar ultra-clear embossed glass, the composition of the weight percentage of each component of the glass base layer is:

[0059] SiO 2 72.50%

[0060] al 2 o 3 2.50%

[0061] Fe 2 o 3 0.01%

[0062] CaO 11.00%

[0063] R 2 O 13.50%

[0064] Sb 2 o 3 0.39%

[0065] CeO 2 0.10%

[0066] The formation process of the coating layer on the glass substrate is as follows:

[0067] (1) Preparation of coating nanomaterials;

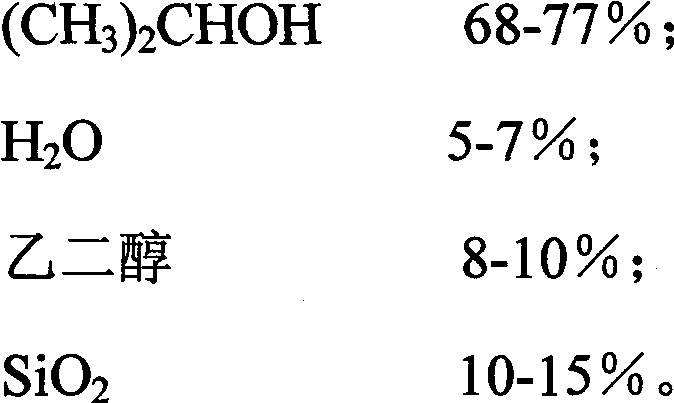

[0068] Form the weight percent of each component of coating film layer is:

[0069] {(CH 3 ) 2 CHOH} 68%;

[0070] (H 2 O) 7%;

[0071] (C 2 h 6 o 2 ) 10%;

[0072] SiO 2 15%

[0073] with SiO 2 As a precursor, the temperature and time of the alcohol reduction process control the reduction reaction cooling and reflux speed to obtain the porous nanomaterial SiO that needs to survive 2 ; After the colloid is obtained, it is diluted with alcohol to co...

Embodiment 2

[0078] An antireflection and high transmittance coated solar ultra-clear embossed glass, the composition of the weight percentage of each component of the glass base layer is:

[0079] SiO 2 73.50%

[0080] al 2 o 3 0.50%

[0081] Fe 2 o 3 0.006%

[0082] CaO 8.00%

[0083] MgO 4.00%

[0084] R 2 O 13.50%

[0085] Sb 2 o 3 0.10%

[0086] CeO 2 0.394%

[0087] The formation process of the coating layer on the glass substrate is as follows:

[0088] (1) Preparation of coating nanomaterials;

[0089] Form the weight percent of each component of coating film layer is:

[0090] {(CH 3 ) 2 CHOH} 77%;

[0091] (H 2 O) 5%;

[0092] (C 2 h 6 o 2 ) 8%;

[0093] SiO 2 10%

[0094] with SiO 2 As a precursor, the temperature and time of the alcohol reduction process control the reduction reaction cooling and reflux speed to obtain the porous nanomaterial SiO that needs to survive 2 ; After the colloid is obtained, it is...

Embodiment 3

[0099] An antireflection and high transmittance coated solar ultra-clear embossed glass, the composition of the weight percentage of each component of the glass base layer is:

[0100] SiO 2 74.00%

[0101] al 2 o 3 0.50%

[0102] Fe 2 o 3 0.006%

[0103] CaO 10.194%

[0104] R 2 O 14.50%

[0105] Sb 2 o 3 0.40%

[0106] CeO 2 0.40%

[0107] The formation process of the coating layer on the glass substrate is as follows:

[0108] (1) Preparation of coating nanomaterials;

[0109] Form the weight percent of each component of coating film layer is:

[0110] {(CH 3 ) 2 CHOH} 70%;

[0111] (H 2 O) 6%;

[0112] (C 2 h 6 o 2 ) 9%;

[0113] SiO 2 15%

[0114] with SiO 2 As a precursor, the temperature and time of the alcohol reduction process control the reduction reaction cooling and reflux speed to obtain the porous nanomaterial SiO that needs to survive 2 ; After the colloid is obtained, it is diluted with alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com