Low-radiation coated glass

A low-e coating and glass technology, which is applied to windshields, glass/slag layered products, windows, etc., can solve the problems of low-e glass performance degradation and poor Ag film quality, so as to reduce surface roughness and low Radiation rate, uniform growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

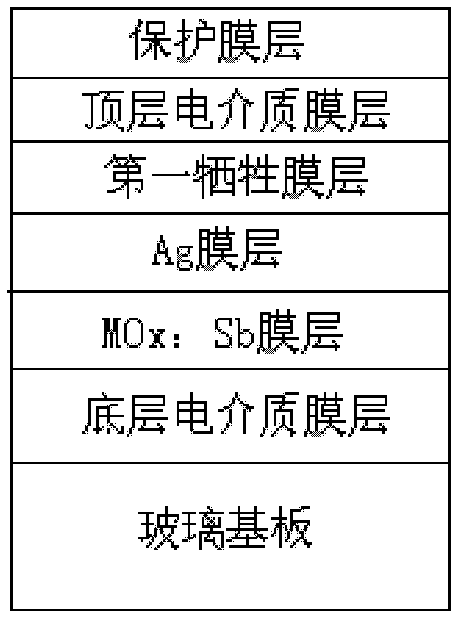

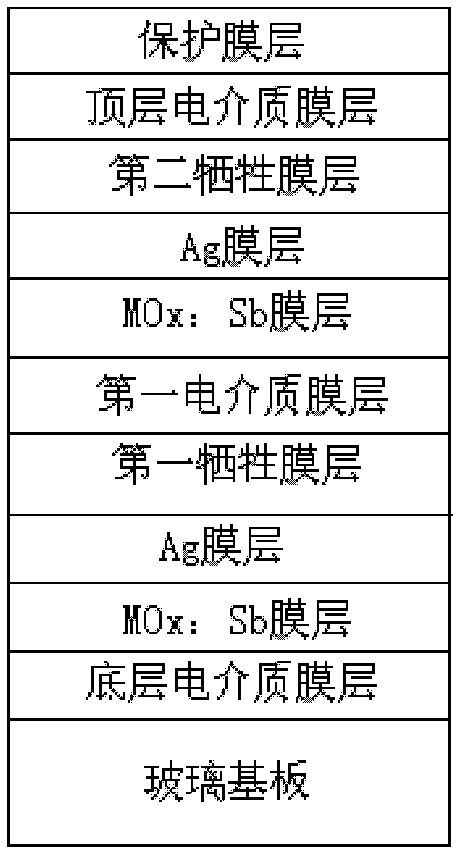

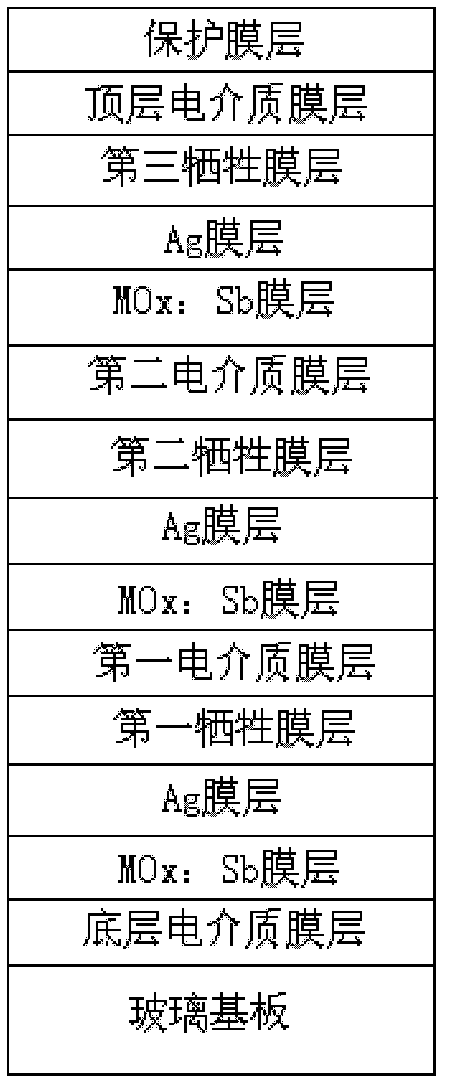

Image

Examples

Embodiment 1

[0045] Embodiment 1 performance test is as follows:

[0046] Optical performance test

[0047] Before heat treatment, the emissivity of a single piece of low-emissivity coated glass is 0.044, and the visible light transmittance is 80.1%. After bending and heating, the emissivity of a single piece of low-emissivity coated glass is 0.028, and the visible light transmittance is 83.2%. Then The low-emissivity coated laminated glass obtained after washing, assembling and other processes has been tested to have a visible light transmittance of 75.8% and a direct solar transmittance of 43%.

[0048] physical properties

[0049] According to GB9656-2003, impact test, radiation resistance test, damp heat cycle test, etc. can meet the requirements. After testing, the knock test grade is 4, which shows that the adhesion of the film layer to glass and PVB is very good.

Embodiment 2

[0050] Embodiment 2 performance test is as follows:

[0051] Optical performance test

[0052]Before heat treatment, the emissivity of a single piece of low-emissivity coated glass is 0.049, and the visible light transmittance is 79.8%. After bending and heating, the emissivity of a single piece of low-emissivity coated glass is 0.031, and the visible light transmittance is 83%. Then The low-emissivity coated laminated glass obtained after washing and laminating processes has been tested to have a visible light transmittance of 75.5% and a solar direct transmittance of 43.2%.

[0053] physical properties

[0054] According to GB9656-2003, impact test, radiation resistance test, damp heat cycle test, etc. can meet the requirements. After testing, the knock test grade is 4, which shows that the adhesion of the film layer to glass and PVB is very good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com