A kind of borosilicate glass, glass-metal matching sealing piece and its preparation method and application

A glass and metal technology, applied in the field of glass and high temperature vacuum solar collectors, can solve the problems of poor wettability, poor cold and thermal shock resistance, poor light transmittance and weather resistance of molybdenum group glass, and achieve strong weather resistance. , The effect of stable quality and reducing technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The borosilicate glass of the present invention has good performance, and its coefficient of expansion is close to Kovar alloy, and can be matched and sealed with Kovar alloy, and its composition is: B 2 o 3 10.0wt%, Al 2 o 3 6.5 wt%, Na 2 O 6.5 wt%, K 2 O 1.5 wt%, CaO 0.5 wt%, Li 2 O 0.5wt%, SiO 2 In addition, in addition to the above-mentioned components, iron impurities are inevitably mixed in the glass, and the iron content is controlled to be ≤150ppm during preparation. According to the composition of the above glass components, select quartz sand, aluminum hydroxide, anhydrous borax, boric acid, soda ash, potassium carbonate, lithium carbonate, calcite, fluorite, and table salt as raw materials to prepare glass. When selecting raw materials, the dosage requirements of each raw material It is determined according to the content in the glass composition, and the iron content of each mineral raw material is ≤50ppm.

[0029] According to the use of the glass...

Embodiment 2

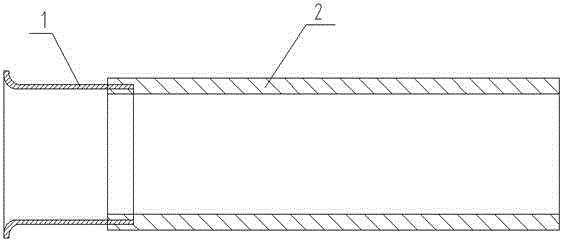

[0032] The glass tube prepared above can be matched and sealed with Kovar alloy to obtain a glass-metal matching seal, such as figure 1 shown. The specific steps are: stamping and turning 4J29 Kovar alloy to obtain a Kovar alloy ring, the outer diameter of the alloy ring is 125mm, the inner diameter is 118mm, the length of one end flanging is 3.5mm, the length is 25mm, and the wall thickness is 0.8mm. Clean the Kovar alloy ring, and after cleaning, treat it in wet hydrogen at 1000°C for 30 minutes, and then use a high-temperature flame to carry out matching sealing between the borosilicate glass tube and the Kovar alloy. The glass tubes are sealed with a sealing length of 5 mm, and annealed at 560° C. for 1 hour after sealing to eliminate the glass-metal sealing stress and obtain a glass-metal matching sealing piece. The obtained sealing piece can be used to cover glass tubes with trough-type high-temperature vacuum solar heat collection tubes, has strong weather resistance, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com