Method for electrochemical codeposition of CZTS (Se) films in deep eutectic solution

A deep eutectic and electrochemical technology, applied in the field of solar cells, can solve the problems of lower conversion efficiency and disordered crystal structure, and achieve the effects of low vapor pressure, low dissolution temperature and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of deep eutectic solution

[0047] Mix choline chloride and urea evenly, heat to 90°C, stir for 6 hours, cool to room temperature, and obtain a deep eutectic solution; the molar ratio of choline chloride to solvent is 1:2;

[0048] (2) Preparation of plating solution

[0049] Add copper chloride, zinc chloride, tin chloride and thioacetamide to the deep eutectic solution prepared in step (1), stir evenly with magnetic force, heat to 80°C, and continue stirring for 2 hours to obtain a uniformly dispersed plating solution ; The concentration of copper chloride in the plating solution is 8mmol / L, the concentration of zinc chloride is 12mmol / L, the concentration of tin chloride is 12mmol / L, and the concentration of thioacetamide is 32mmol / L;

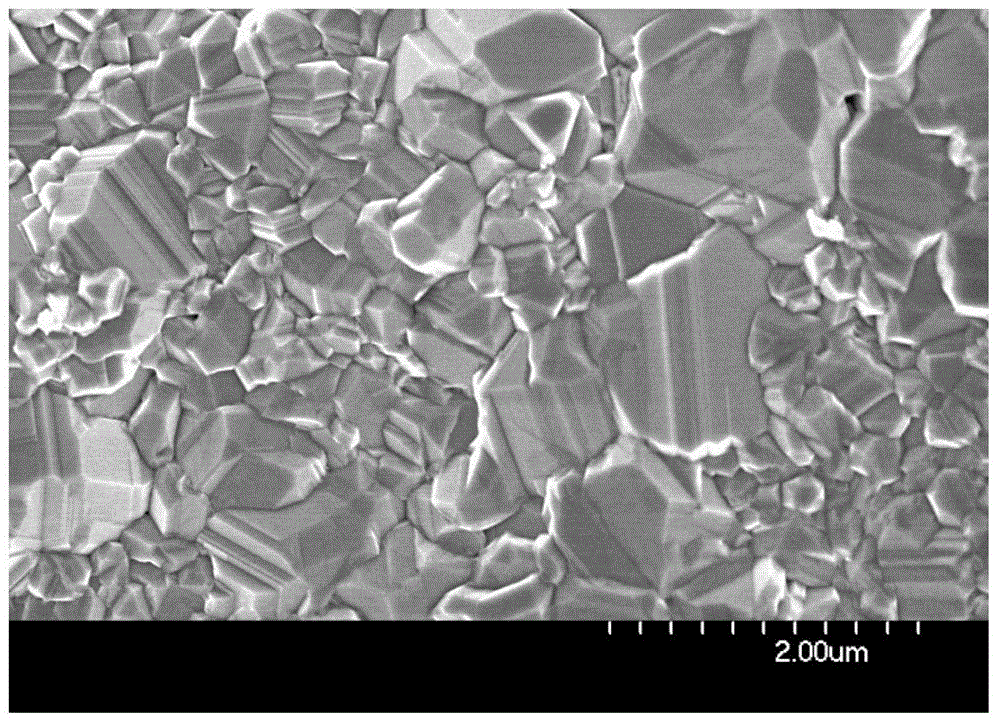

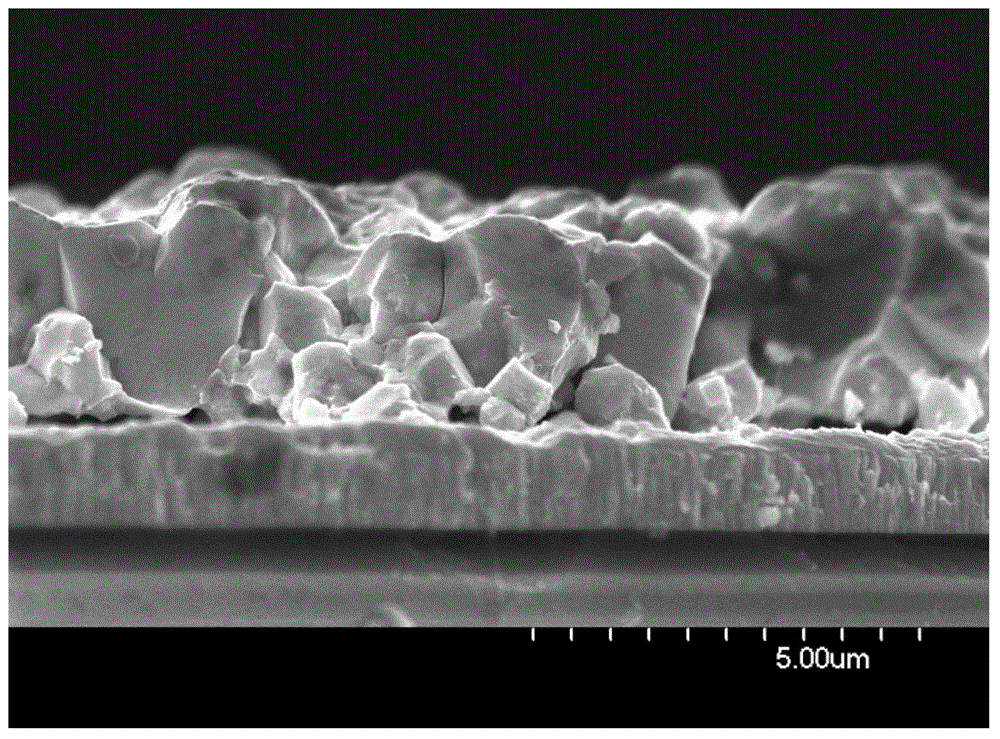

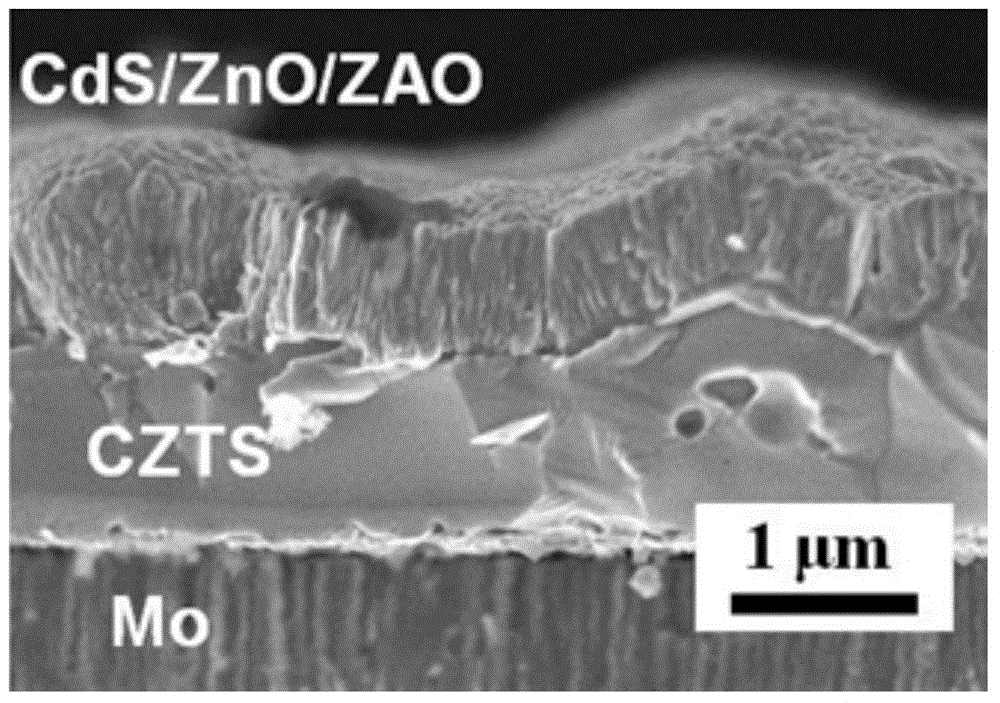

[0050] (3) Preparation of CZTS film prefabricated layer

[0051] The soda-lime glass substrate material with a 1 μm thick Mo electrode was ultrasonically cleaned three times in 10% NaOH solution and absolute ethanol,...

Embodiment 2

[0061] (1) Preparation of deep eutectic solution

[0062] Mix choline chloride and ethylene glycol evenly, then add an appropriate amount of deionized water, heat to 90°C, stir for 6 hours, cool to room temperature, and obtain a deep eutectic solution; the molar ratio of choline chloride to solvent 1: 2.5, the volume ratio of the solvent and deionized water is 7: 2;

[0063] (2) Preparation of plating solution

[0064] Add copper sulfate, zinc sulfate, tin sulfate and selenic acid to the deep eutectic solution prepared in step (2), stir evenly with magnetic force, heat to 70° C., and continue stirring for 2 hours to obtain a uniformly dispersed plating solution; the plating solution The concentration of copper sulfate in the medium is 10mmol / L, the concentration of zinc sulfate is 15mmol / L, the concentration of tin sulfate is 15mmol / L, the concentration of selenic acid is 40mmol / L;

[0065] (3) Preparation of CZTSe thin film prefabricated layer

[0066] The Mo metal foil su...

Embodiment 3

[0076] (1) Preparation of deep eutectic solution

[0077] Mix choline chloride and oxalic acid evenly, then add an appropriate amount of deionized water, heat to 50°C, stir for 4 hours, cool to room temperature, and obtain a deep eutectic solution; the molar ratio of the choline chloride to the solvent is 1 : 1, the volume ratio of the solvent and deionized water is 7: 3;

[0078] (2) Preparation of plating solution

[0079] Add copper nitrate, zinc nitrate, tin nitrate and selenium chloride to the deep eutectic solution prepared in step (1), stir evenly with magnetic force, heat to 60°C, and continue stirring for 3h to obtain a uniformly dispersed plating solution; The concentration of copper nitrate in the liquid is 20mmol / L, the concentration of zinc nitrate is 25mmol / L, the concentration of tin nitrate is 30mmol / L, the concentration of selenium chloride is 60mmol / L;

[0080] (3) Preparation of CZTSe thin film prefabricated layer

[0081] The Ti metal foil substrate mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com