Graphene/silver molybdenum oxide compound visible-light catalyst and preparation method thereof

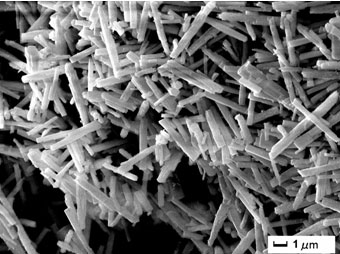

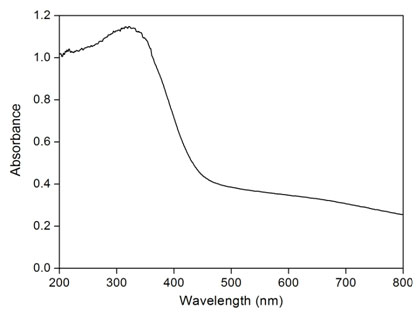

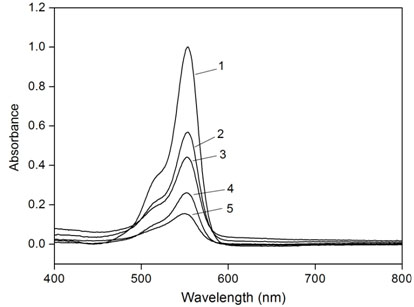

A silver molybdate and visible light technology is applied in the field of composite materials and photocatalysis, which can solve the problems of multi-component mixing of silver molybdate, uneven morphology, poor visible light photocatalysis effect, etc., and achieves simple and safe preparation process and uniform size. , the effect of good electron transport ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 5 mg of graphene oxide to 20 mL of distilled water, and ultrasonicate for 3 hours to obtain a graphene oxide dispersion, then add 8 mmol of silver nitrate to the above graphene oxide dispersion, stir on a magnetic stirrer, and add to the solution 20 ml of 2 mmol ammonium heptamolybdate aqueous solution was added dropwise to the solution, and the pH value of the solution was adjusted to 1.5 with nitric acid solution; finally, the above mixed solution was transferred to a 100 ml hydrothermal reaction kettle, and reacted at 140°C for 24 hours; hydrothermal reaction After the final product is separated by high-speed centrifugation, it is washed with distilled water and absolute ethanol, repeated centrifugation and washing several times, and then dried in a vacuum oven.

Embodiment 2

[0022] Add 10 mg of graphene oxide to 20 mL of distilled water, ultrasonicate for 5 hours to obtain a graphene oxide dispersion, then add 15 mmol of silver nitrate to the above graphene oxide dispersion, stir on a magnetic stirrer, and add to the solution 20 ml of 2 mmol ammonium heptamolybdate solution was added dropwise to the solution, and the pH value of the solution was adjusted to 1.5 with nitric acid solution; finally, the above mixed solution was transferred to a 100 ml hydrothermal reaction kettle, and reacted at 160°C for 20 hours; hydrothermal reaction After the final product is separated by high-speed centrifugation, it is washed with distilled water and absolute ethanol, repeated centrifugation and washing several times, and then dried in a vacuum oven.

Embodiment 3

[0024] Add 20 mg of graphene oxide to 20 mL of distilled water, and obtain a graphene oxide dispersion by ultrasonication for 4 hours, then add 4 mmol of silver nitrate to the above graphene oxide dispersion, stir on a magnetic stirrer, and add to the solution 20 ml of 1 mmol ammonium heptamolybdate solution was added dropwise to the solution, and then the pH of the solution was adjusted to 2.0 with nitric acid solution; finally, the above mixed solution was transferred to a 100 ml hydrothermal reaction kettle, and reacted at 140°C for 24 hours; after the hydrothermal reaction After high-speed centrifugation, the product was washed with distilled water and absolute ethanol, repeated centrifugation and washing several times, and then dried in a vacuum oven.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com