Cobalt molybdate-graphene nano compound and preparation method thereof

A nanocomposite, graphene technology, applied in cobalt compounds, carbon compounds, nanotechnology and other directions, to achieve the effects of large surface area, good application prospects and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

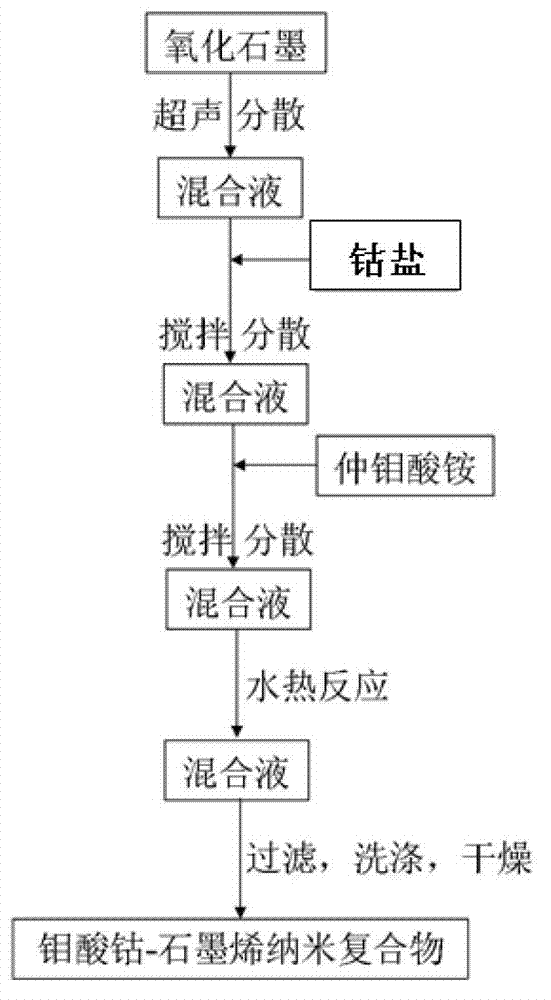

[0026] Implementation example 1: The preparation method of cobalt molybdate-graphene (50 wt%) nanocomposite of the present invention comprises the following steps:

[0027] In the first step, graphite oxide is prepared by the Hummer method. Add 10 g of graphite powder to potassium persulfate (5 g) and phosphorus pentoxide (5 g) in concentrated sulfuric acid solution (15 mL) at 80 °C, pre-oxidize for 6 hours, then cool to room temperature, filter, and wash to medium sex. Add pre-oxidized graphite powder (10 g) to 230 mL of concentrated sulfuric acid solution at 0°C, then carefully add 30 g of potassium permanganate, then react at 35°C for 2 hours, and finally add 1L of deionized water to the reaction solution And 25mL of 30% hydrogen peroxide to terminate the reaction, filter, wash, and dialyze to obtain graphite oxide; place 80 mg of graphite oxide in 80mL water for ultrasonic dispersion for 120min;

[0028] In the second step, 0.366 mmol of cobalt nitrate was added to the...

Embodiment 2

[0032] Implementation example 2: The preparation method of cobalt molybdate-graphene (42 wt%) nanocomposite of the present invention comprises the following steps:

[0033] The first step, the preparation of graphite oxide is the same as in Example 1, and 80 mg of graphite oxide is placed in 80 mL of water for ultrasonic dispersion for 60 min;

[0034] In the second step, 0.5 mmol of cobalt acetate is added to the solution of the first step, stirred and dissolved, and stirred for 90 minutes;

[0035] In the third step, 0.071 mmol of ammonium paramolybdate was added to the mixed solution in the second step, and stirred for 30 minutes to adjust the pH value to 7;

[0036] The fourth step is to transfer the mixed solution of the third step to a hydrothermal kettle for reaction, the reaction temperature is 140°C, and the reaction time is 16h;

[0037] In the fifth step, the product of the fourth step was separated by filtration, washed, and dried to obtain a cobalt molybdate-gr...

Embodiment 3

[0038] Implementation example 3: The preparation method of cobalt molybdate-graphene (27 wt%) nanocomposite of the present invention comprises the following steps:

[0039] The first step, the preparation of graphite oxide is the same as in Example 1, and 80 mg of graphite oxide is placed in 80 mL of water for ultrasonic dispersion for 90 min;

[0040] In the second step, 1 mmol of cobalt nitrate is added to the solution of the first step, stirred and dissolved, and stirred for 40 minutes;

[0041] In the third step, 0.142 mmol of ammonium paramolybdate was added to the mixed solution in the second step, and stirred for 60 minutes to adjust the pH value to 7;

[0042] The fourth step is to transfer the mixed solution of the third step to a hydrothermal kettle for reaction, the reaction temperature is 180°C, and the reaction time is 12h;

[0043] In the fifth step, the product of the fourth step was separated by filtration, washed, and dried to obtain a cobalt molybdate-grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com