Plant nutrient solution for soilless culture of tomato

A plant nutrient solution and soilless cultivation technology, applied in the field of plant nutrient solution for tomato soilless cultivation, to achieve the effect of promoting growth, fruit ears and excellent yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

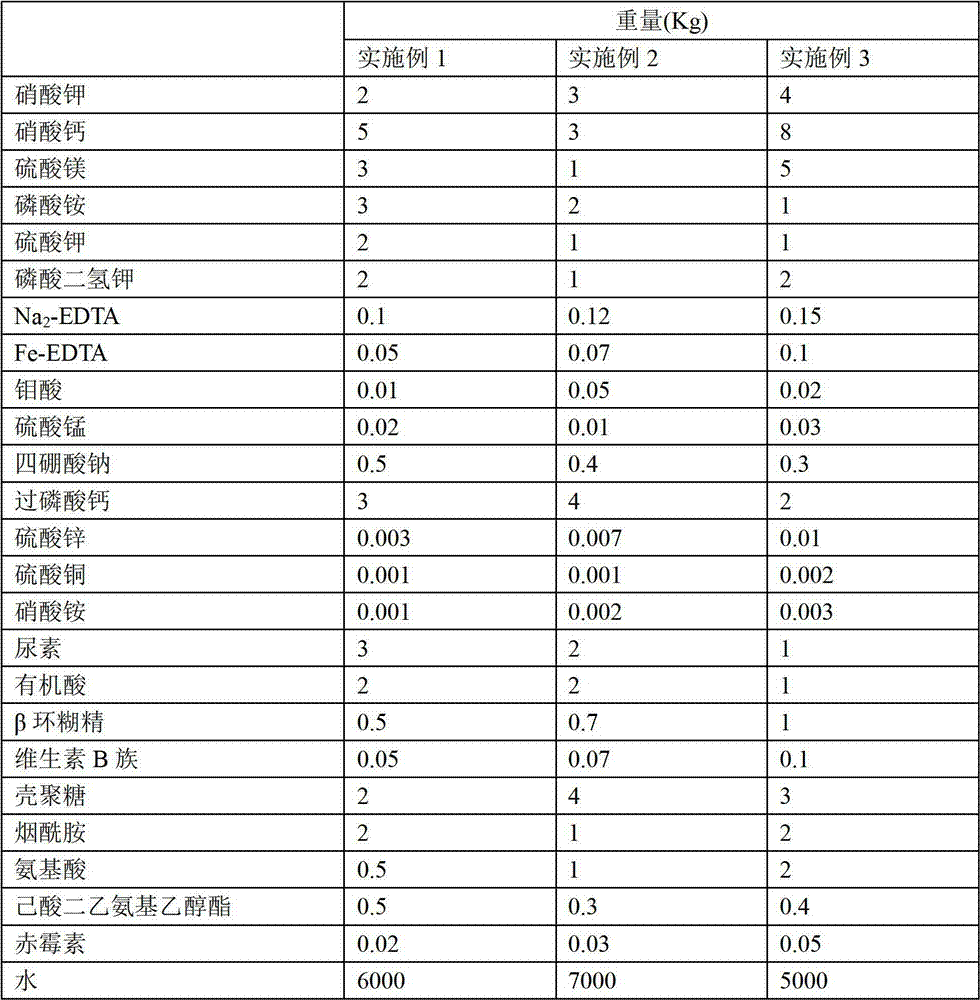

[0013] The components were prepared in the weight ratios shown in Table 1.

[0014] The weight proportion of table 1 embodiment 1~embodiment 3

[0015]

[0016] In the above embodiments, the water is local tap water, and the hardness is generally 50-70.

[0017] Amino acid adopts tryptophan.

[0018] The organic acid adopts malic acid.

[0019] Vitamin B family adopts vitamin B6.

[0020] After the above raw materials are mixed uniformly according to the specified ratio, it can be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com