Method for preparing copper molybdate by using cation membrane electrolysis method

A technology of cationic membrane and copper molybdate, which is applied in the direction of electrolysis process, electrolysis components, organic diaphragm, etc., can solve the problems of reaction time of additives, etc., and achieve the effect of easy operation, simple process and large synthesis amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

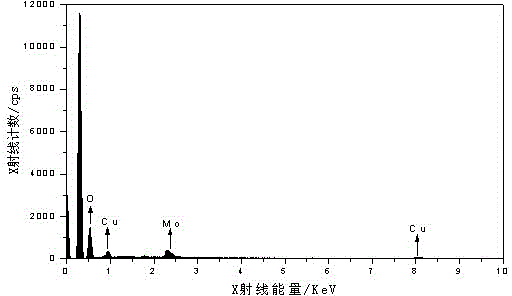

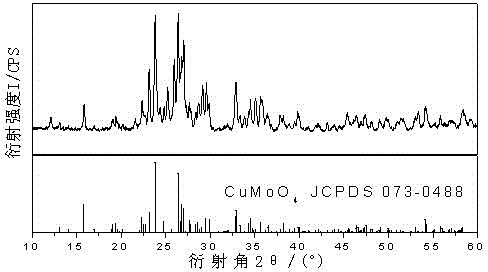

[0028] With 95mL of 0.01mol / L sodium molybdate solution as anolyte, 90mL of 0.01mol / L sodium hydroxide solution as catholyte, copper sheet as anode and titanium mesh as cathode, electrolyze at a constant voltage of 50V for 10min. The electrolyzed product was washed three times with deionized water, and then dried in a blast drying oven at a constant temperature of 60°C for 2 hours. Raise the temperature to 500°C at a heating rate of min, then roast at constant temperature for 1h, and cool to room temperature naturally. The obtained product is tested for EDS and XRD, such as figure 1 and figure 2 .

[0029] By observing figure 1 From the EDS diagram, it can be obtained that there are only three elements of Cu, Mo and O in the product. By observing figure 2 In the XRD pattern, it can be confirmed that the obtained product is CuMoO 4 .

Embodiment 2

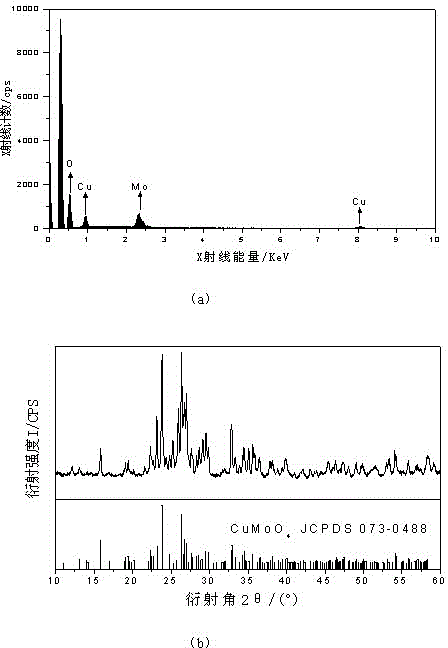

[0031] With 95mL of 0.01mol / L sodium molybdate solution as anolyte, 90mL of 0.01mol / L sodium hydroxide solution as catholyte, copper sheet as anode and titanium mesh as cathode, electrolyze 306S with a constant current of 0.6A (Electrolysis time is based on Na + The theoretical electricity consumed by all the ions transferred to the cathode chamber is calculated, that is, ). The electrolyzed product was washed three times with deionized water, and then dried in a blast drying oven at a constant temperature of 60°C for 2 hours. The temperature was raised to 500°C at a heating rate of 1 min, then roasted at a constant temperature for 1 h, and cooled to room temperature naturally. The obtained product is tested for EDS and XRD, such as image 3 .

[0032] By observing image 3 From the EDS diagram of (a), it can be obtained that there are only three elements of Cu, Mo, and O in the product. By observing image 3 The XRD pattern in (b), it can be confirmed that the obtaine...

Embodiment 3

[0034] With 95mL of 0.01mol / L sodium molybdate solution as anolyte, 90mL of 0.01mol / L sodium chloride solution as catholyte, copper sheet as anode and titanium mesh as cathode, electrolyze 306S with a constant current of 0.6A . Wash the electrolyzed product three times with deionized water, and then dry it in a blast drying oven at a constant temperature of 60°C for 2 hours. Put the product after repeated electrolytic drying in a muffle furnace, and heat it in an air atmosphere at 2.5°C / The temperature was raised to 500°C at a heating rate of 1 min, then roasted at a constant temperature for 1 h, and cooled to room temperature naturally. The obtained product is tested for EDS and XRD, such as Figure 4 .

[0035] By observing Figure 4 From the EDS diagram of (a), it can be obtained that there are only three elements of Cu, Mo, and O in the product. By observing Figure 4 The XRD pattern in (b), it can be confirmed that the obtained product is CuMoO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com