Molybdenum trioxide laminated nanometer bar and preparation method

A molybdenum trioxide and nanorod technology, applied in nanomaterials and nanometer fields, can solve the problem of high degree of controllability, and achieve the effect of good reproducibility and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of molybdenum trioxide nanorod, its step is:

[0022] 1. Add 1gMoO 3 Dissolve the powder in 50ml of hydrogen peroxide (concentration: 30%), stir vigorously for 48 hours, then add 30ml of deionized water, stir and age for 48 hours to form a yellow transparent sol;

[0023] 2. Transfer the yellow transparent sol obtained in step 1 directly into a stainless steel reaction kettle with a polytetrafluoroethylene substrate, conduct a hydrothermal reaction at 180°C for 4 days, and cool naturally to room temperature to obtain a hydrothermal product;

[0024] 3. Wash and filter the hydrothermal product obtained in step 2 with absolute ethanol for 2 times, then with deionized water for 2 times, and dry at 80°C for 12 hours to obtain a light blue molybdenum trioxide laminated nanorod product.

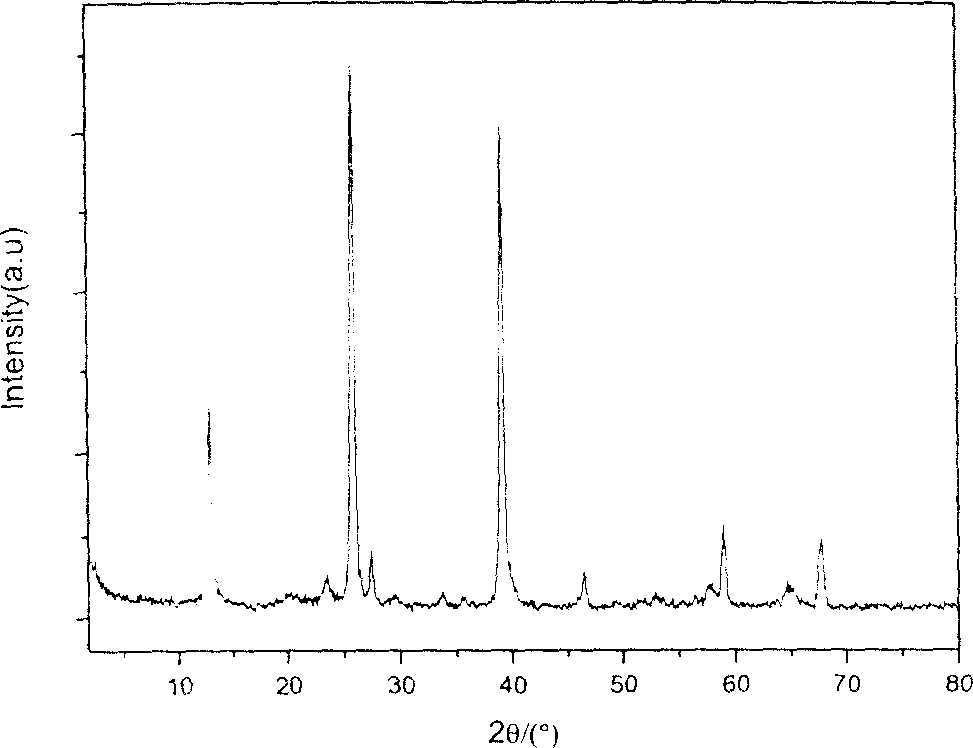

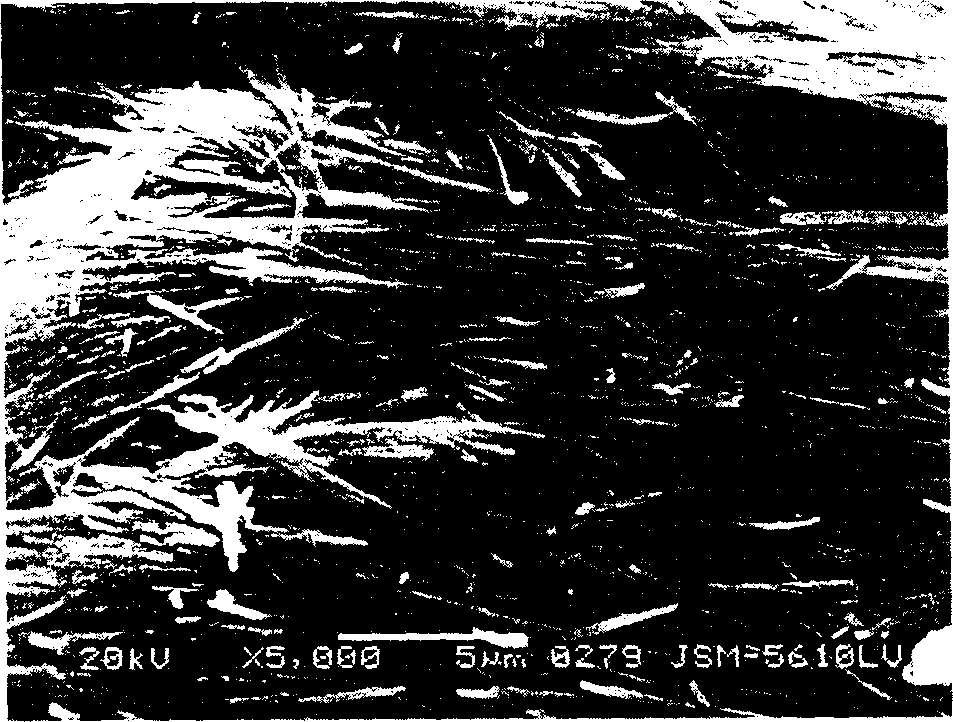

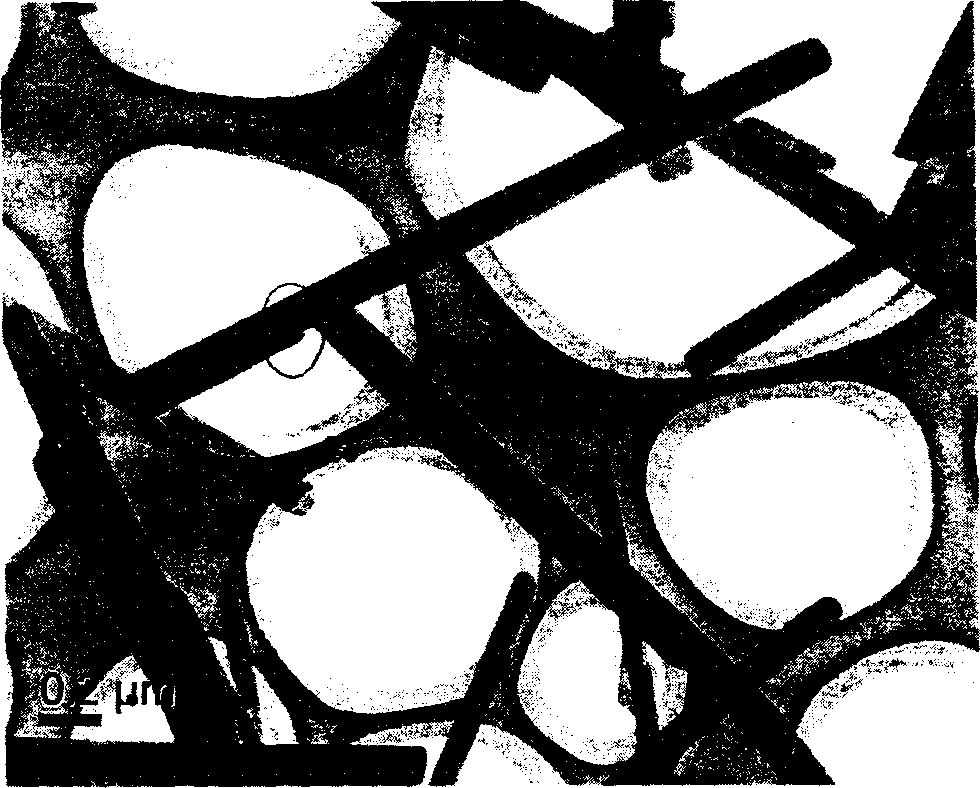

[0025] The analysis and test of the obtained molybdenum trioxide product shows (see attached figure) that the synthesized product is in the shape of a short rod, the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com