Environment-friendly copper clad laminate for LED monochrome display, glue solution and preparation method

A copper-clad laminate and environment-friendly technology, which is applied in the field of copper-clad laminates for environment-friendly LED monochrome displays, can solve the problems of serious environmental pollution, high manufacturing cost, and poor heat resistance, and achieve reduced incineration, excellent heat dissipation, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of glue for copper clad laminates

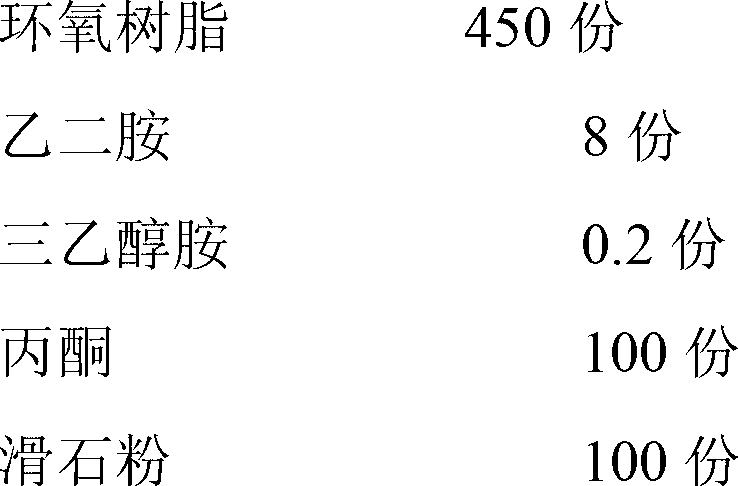

[0032] Components (parts by weight) of glue for copper clad laminates:

[0033]

[0034] The mass percentage of talcum powder in the glue solution is 15.2%.

[0035] The preparation method of glue for copper clad laminates: mix 8 parts of ethylenediamine, 0.2 parts of triethanolamine and 100 parts of acetone, and stir for 3 hours at a speed of 900 rpm; after it is completely dissolved, add 450 parts of epoxy resin, and Stir fully at 1000rpm for 4 hours; after mixing evenly, add 100 parts of talc powder, disperse at high shear at 3000rpm for 1 hour, then stir at 1000rpm for 7 hours, and then fully mature.

Embodiment 2

[0036] Embodiment 2: Preparation of glue solution for copper clad laminate

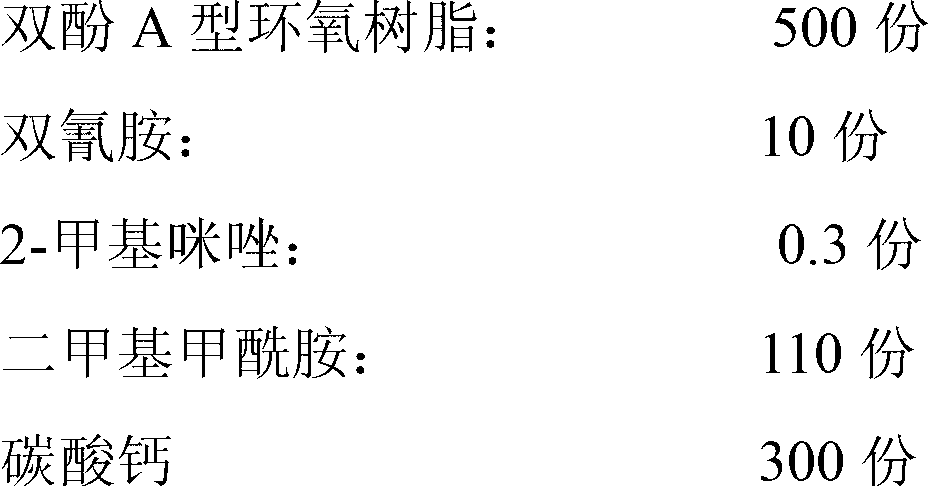

[0037] Components (parts by weight) of glue for copper clad laminates:

[0038]

[0039] The mass percent composition of calcium carbonate in the glue solution is 32.6%.

[0040] The preparation method of glue for copper clad laminates: mix 10 parts of dicyandiamide, 0.3 parts of 2-methylimidazole and 110 parts of dimethylformamide, and stir for 4 hours at a speed of 1000 rpm; after it is completely dissolved, add dicyandiamide 500 parts of phenol A type epoxy resin, fully stirred at 1200 rpm for 5 hours; after mixing evenly, 300 parts of calcium carbonate were added, and dispersed at high shear at 4000 rpm for 1 hour, then stirred at 1200 rpm for 8 hours, completely Just after ripening.

Embodiment 3

[0041] Embodiment 3: Preparation of glue solution for copper clad laminate

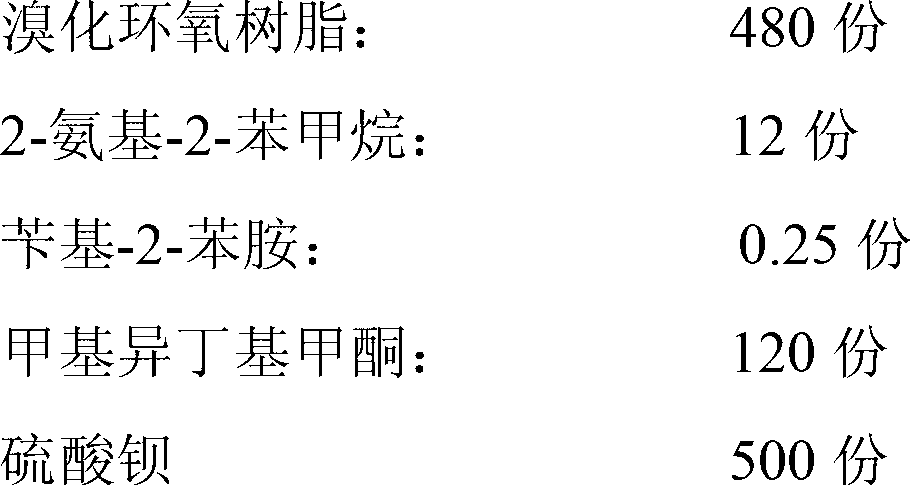

[0042] Components (parts by weight) of glue for copper clad laminates:

[0043]

[0044] The mass percent composition of barium sulfate in glue solution is 45%.

[0045]The preparation method of glue for copper clad laminates: mix 12 parts of 2-amino-2-phenylmethane, 0.25 parts of benzyl-2-aniline and 120 parts of methyl isobutyl ketone, and stir for 5 hours at a speed of 1200 rpm; After dissolving, add 480 parts of brominated epoxy resin and stir fully at 1400rpm for 4 hours; after mixing evenly, add 500 parts of barium sulfate, disperse with high shear at 5000rpm for 1 hour, and then stir at 1400rpm 6 hours, after fully ripening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com