Preparation method and application of allulose

A technique of psicose and glucose, applied in the field of psicose preparation, can solve the problems of slow reaction speed, low D-psicose conversion rate, long time consumption, etc., achieves fast reaction speed and overcomes enzyme stability Poor performance, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

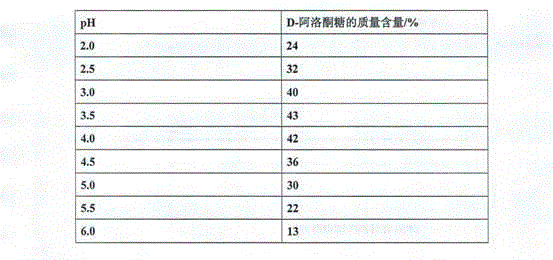

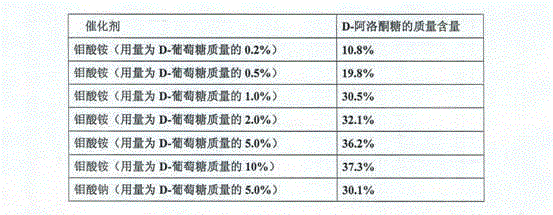

Method used

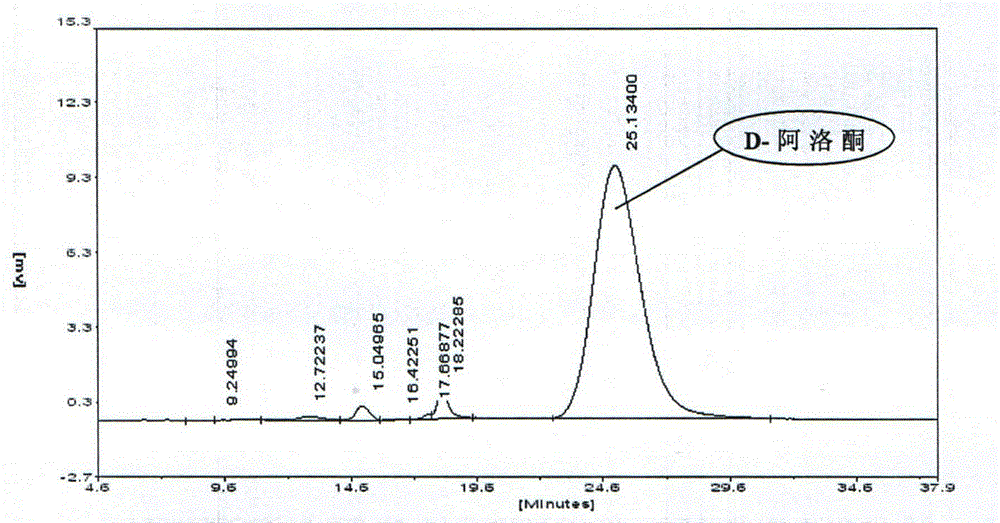

Image

Examples

Embodiment 1

[0036] 1. Solution preparation: Take 1000g of glucose, add 9000g of pure water, and prepare 10000g of glucose solution with a mass percentage and mass concentration of 10%.

[0037] 2. Chemical isomerization reaction: Add 10g of ammonium molybdate according to 1% of the dry matter of glucose, adjust the pH value of the solution to 2.5, raise the temperature to 80°C, and keep it warm for 2 hours to make glucose isomerization into D-psicose , to obtain a mixture of D-psicose and glucose, the dry matter concentration of which is 8%, the purity of D-psicose is 28%, and the conductivity is 10000us / cm.

[0038] 3. Decolorization and filtration: When the isomerization liquid is at 70°C, add 10g of powdered activated carbon according to 1% of its dry matter mass, keep it warm and stir for 30 minutes, and filter it with a plate and frame filter to obtain the isomerization decolorization liquid. The index is: dry matter mass The concentration is 8%, the purity of D-psicose is 28.56%, an...

Embodiment 2

[0043] 1. Solution preparation: Take 3000g of glucose, add 7000g of pure water, and prepare 10000g of glucose solution with a mass percentage mass concentration of 30%.

[0044] 2. Chemical isomerization reaction: add 300g of ammonium molybdate according to 10% of the dry matter of glucose, adjust the pH value of the solution to 5.0, raise the temperature to 120°C, and keep it warm for 5 hours to make glucose isomerization into D-psicose , to obtain a mixture of D-psicose and glucose, the dry matter concentration of which is 28%, the purity of D-psicose is 35%, and the conductivity is 20000us / cm.

[0045] 3. Decolorization and filtration: Add 450g of powdered activated carbon to the isomerization liquid at 80°C according to 15% of its dry matter mass, keep it warm and stir for 40 minutes, and filter it with a plate and frame filter to obtain the isomerization decolorization liquid. The index is: dry matter mass The concentration is 28%, the purity of D-psicose is 35.27%, and t...

Embodiment 3

[0050] 1. Solution preparation: Take 2000g of glucose, add 8000g of pure water, and prepare 10000g of glucose solution with a mass percentage and mass concentration of 20%.

[0051] 2. Chemical isomerization reaction: Add 100g of ammonium molybdate according to 5% of the dry matter of glucose, adjust the pH value of the solution to 4.0, raise the temperature to 100°C, and keep warm for 3.5 hours to make glucose isomerization into D-psicose , to obtain a mixture of D-psicose and glucose, the dry matter concentration of which is 18%, the purity of D-psicose is 32%, and the conductivity is 15000us / cm.

[0052] 3. Decolorization and filtration: Add 200g of powdered activated carbon to the isomerization liquid at 75°C according to 10% of its dry matter mass, heat and stir for 35 minutes, and filter it with a plate and frame filter to obtain the isomerization decolorization liquid. The index is: dry matter mass The concentration is 18%, the purity of D-psicose is 32.17%, and the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com