Preparation and application of carbon dioxide electrochemical reduction catalyst

A carbon dioxide, carbon-based catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of metal atom agglomeration, catalyst performance degradation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

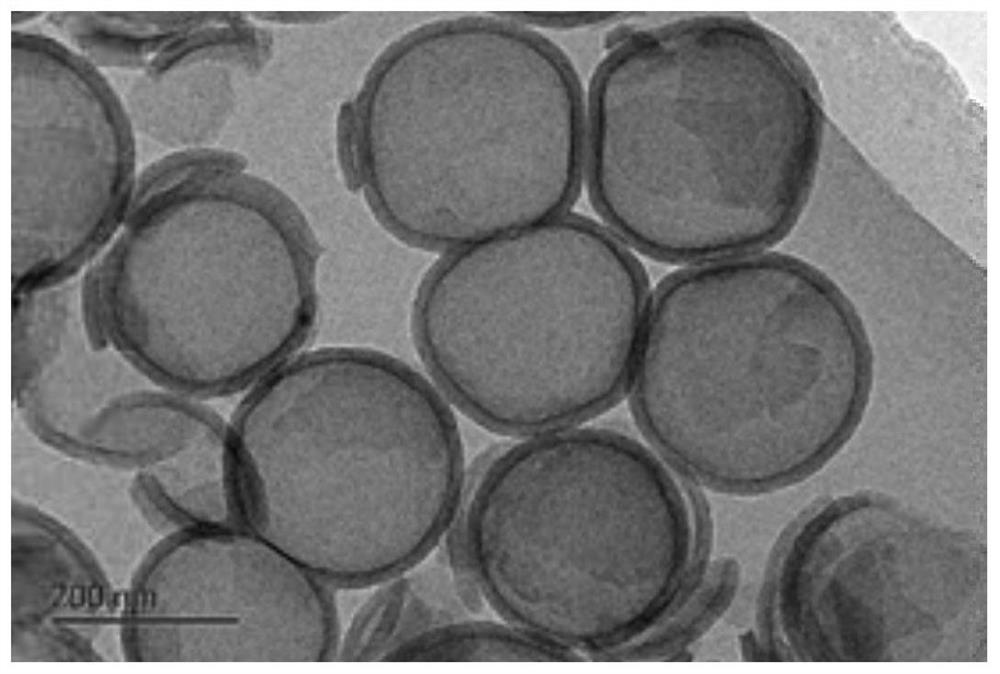

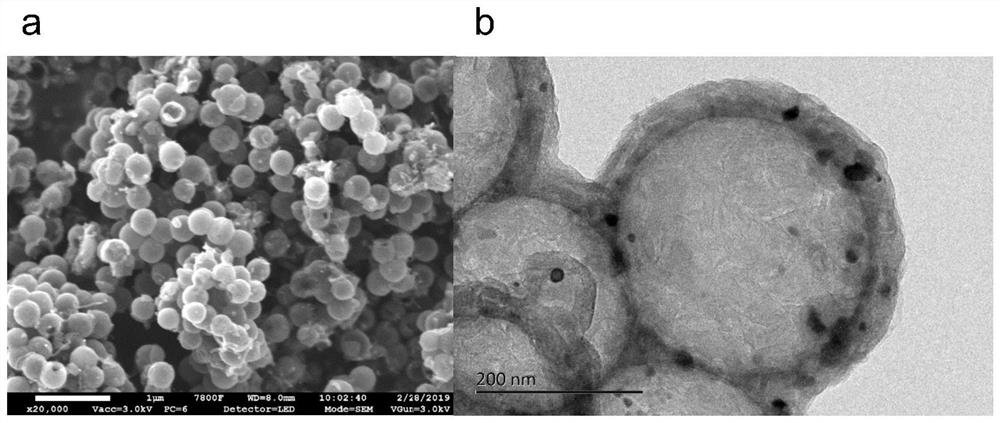

[0036] 1) Add solution A: 2.55ml ethyl orthosilicate into 45ml ethanol and stir; add solution B: 6ml 25% ammonia water and 9ml water into 30ml ethanol and stir. Add solution A into solution B and stir for 1 hour; pour solution B into the reaction kettle for hydrothermal treatment at 100°C for 24 hours, rinse the product after hydroheating with distilled water for more than three times, then dry it at 70°C for 8 hours, take the dried sample for 600°C Argon high-temperature calcination for 3h, heating rate 2 ℃ / min. Add 3g of the calcined product to 40ml (20%) hydrofluoric acid solution and etch for 24h, and finally obtain a hollow carbon sphere support rich in microporous structure.

[0037] 2) Add 0.1g of hollow carbon sphere carrier, 50mg of nickel chloride and 0.6g of melamine into 20ml of ethanol solution, stir at 25°C for 12h, evaporate to dryness in a water bath at 80°C, and then dry for 12h;

[0038] 3) The dried sample was calcined in argon at 1000°C for 1h at a heati...

Embodiment 2

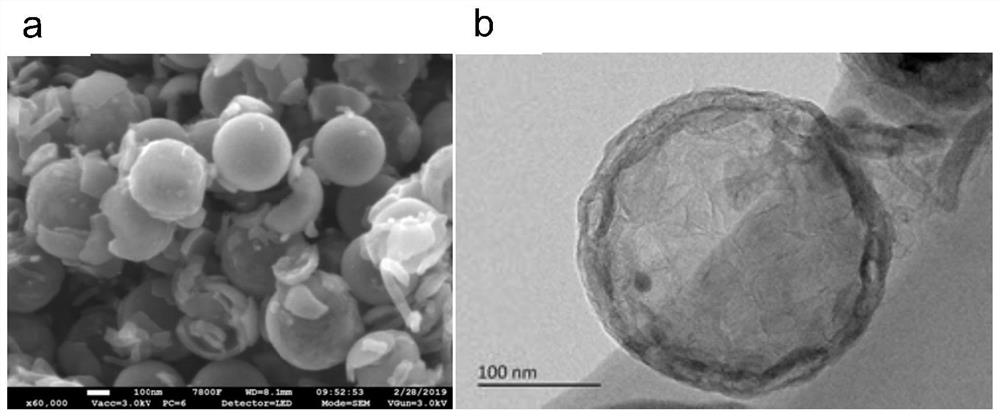

[0044] 1) Add solution A: 2.55ml ethyl orthosilicate into 45ml ethanol and stir; add solution B: 6ml 25% ammonia water and 9ml water into 30ml ethanol and stir. Add solution A into solution B and stir for 1 hour; pour solution B into the reaction kettle for hydrothermal treatment at 100°C for 24 hours, rinse the product after hydroheating with distilled water for more than three times, then dry it at 70°C for 8 hours, take the dried sample for 600°C Argon high-temperature calcination for 3h, heating rate 2 ℃ / min. Add 3g of the calcined product to 40ml (20%) hydrofluoric acid solution and etch for 24h, and finally obtain a hollow carbon sphere support rich in microporous structure.

[0045] 2) Add 0.1g of hollow carbon sphere carrier, 50mg of nickel chloride and 0.6g of melamine into 20ml of ethanol solution, stir at 25°C for 12h, evaporate to dryness in a water bath at 80°C, and then dry for 12h;

[0046] 3) The dried sample was calcined in argon at 900°C for 1h, the heatin...

Embodiment 3

[0049] 1) Add solution A: 2.55ml ethyl orthosilicate into 45ml ethanol and stir; add solution B: 6ml 25% ammonia water and 9ml water into 30ml ethanol and stir. Add solution A into solution B and stir for 1 hour; pour solution B into the reaction kettle for hydrothermal treatment at 100°C for 24 hours, rinse the product after hydroheating with distilled water for more than three times, then dry it at 70°C for 8 hours, take the dried sample for 600°C Argon high-temperature calcination for 3h, heating rate 2 ℃ / min. Add 3g of the calcined product to 40ml (20%) hydrofluoric acid solution and etch for 24h, and finally obtain a hollow carbon sphere support rich in microporous structure.

[0050] 2) Add 0.1g of hollow carbon sphere carrier, 25mg of nickel chloride and 0.6g of melamine into 20ml of ethanol solution, stir at 25°C for 12h, evaporate to dryness in a water bath at 80°C, and then dry for 12h;

[0051] 3) The dried sample was calcined in argon at 1000°C for 1h at a heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com