An ultra-small vanadium carbide embedded carbon nanotube material, a preparing method thereof and an application thereof in a water cracking hydrogen production aspect

A carbon nanotube and ultra-small carbon technology, which is used in the synthesis and application of catalysts, can solve the problems of large VC particle size, single morphology, complex preparation scheme, etc., and achieves short reaction period, low synthesis temperature, and overcoming complicated steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Weigh 1.5g of dicyandiamide, 0.3g of ammonium metavanadate, 0.2g of cobalt nitrate hexahydrate, fully mix and grind for 40min;

[0030] Step 2: Put the raw materials obtained in Step 1 into a porcelain boat, and react in a tube furnace with a vacuum atmosphere. The heating rate is 5°C / min. First, the temperature is raised to 500°C, and kept for 2 hours. 2h, cooled to room temperature to obtain a black powder;

[0031] Step 3: Dissolve the obtained black powder in 0.5M H 2 SO 4 Soak in the middle for 10h, this is to remove the metal element in the sample, after vacuum drying for 6h, grind to get VC / CNTs hydrogen production electrocatalyst.

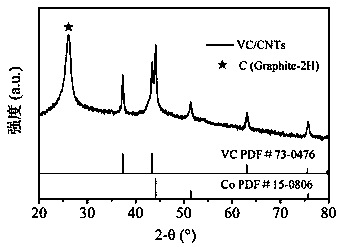

[0032] figure 1 It is the XRD spectrum of the VC / CNTs electrocatalyst prepared in this example. It can be seen from the spectrum that the VC / CNTs sample contains graphitized carbon, VC and cobalt (cobalt embedded in the carbon tube). The characteristics of the three The peak is obvious, indicating that the crystallinity i...

Embodiment 2

[0034] Step 1: Weigh 2g of dicyandiamide, 0.2g of ammonium metavanadate, 0.3g of cobalt nitrate hexahydrate, fully mix and grind for 30min;

[0035] Step 2: Put the raw materials obtained in Step 1 into a porcelain boat, and react in a tube furnace with a vacuum atmosphere. The heating rate is 10°C / min. First, heat up to 500°C, keep it for 2 hours, continue to heat up to 700°C, and keep it warm. 2h, cooled to room temperature to obtain a black powder;

[0036] Step 3: Dissolve the obtained black powder in 0.5M H 2 SO 4 Soak in the middle for 10h, this is to remove the metal element in the sample, after vacuum drying for 6h, grind to get VC / CNTs hydrogen production electrocatalyst.

[0037] figure 2 , 3 It is the SEM and TEM spectrum of the VC / CNTs electrocatalyst prepared in this example. From the SEM picture, it can be seen that the carbon nanotubes have complete morphology and uniform dispersion. From the TEM picture, it can be seen that the presence of cobalt (black pa...

Embodiment 3

[0039] Step 1: Weigh 1g of dicyandiamide, 0.2g of ammonium metavanadate, and 0.1g of nickel nitrate hexahydrate, fully mix and grind for 50 minutes;

[0040] Step 2: Put the raw materials obtained in Step 1 into a porcelain boat and react in a tube furnace with nitrogen as the atmosphere. The heating rate is 7°C / min. First, the temperature is raised to 500°C and kept for 2 hours. 2h, cooled to room temperature to obtain a black powder;

[0041] Step 3: Dissolve the obtained black powder in 0.5M H 2 SO 4 Soak in the middle for 20h, this is to remove the metal element in the sample, vacuum dry for 6h and grind to get VC / CNTs hydrogen production electrocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com