Dual-network hydrogel adsorbent and preparation method thereof and application of dual-network hydrogel adsorbent as heavy metal absorbent

A hydrogel adsorbent, dual network technology, applied in the directions of alkali metal compounds, chemical instruments and methods, adsorbed water/sewage treatment, etc., to achieve the effects of wide source, increased strength, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Add 4.0 g of shredded cotton cloth to 48 mL of aqueous sodium hydroxide solution (14% by mass), place in a low-temperature water bath to pre-cool to 0° C., and stir for 1 min. 48mL urea aqueous solution (mass fraction: 24%) was pre-cooled to 0°C and immediately added to the cotton cloth and sodium hydroxide mixture, stirred vigorously for 2min to obtain a viscous cellulose solution.

[0046] (2) Add 1.0 g of acrylamide, 0.0434 g of MBA and 0.0272 g of KPS into 2 mL of deionized aqueous solution, dissolve completely, and obtain a mixed aqueous solution of acrylamide, crosslinking agent and initiator.

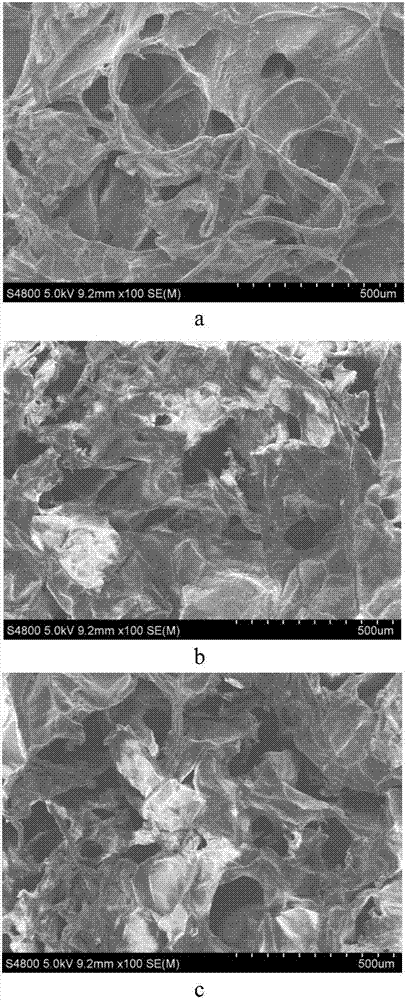

[0047] (3) Add 6mL of (1) to (2) and mix evenly, then add 0.0 / 0.2 / 0.3 / 0.4 / 0.5 / 0.6mL of ECH, mix evenly again, place it in a constant temperature oven at 60°C for 2 hours, take it out, Wash with deionized water until neutral, dry to constant weight, and obtain six kinds of cellulose / acrylamide double network hydrogel materials with different crosslinking degrees.

[00...

Embodiment 2

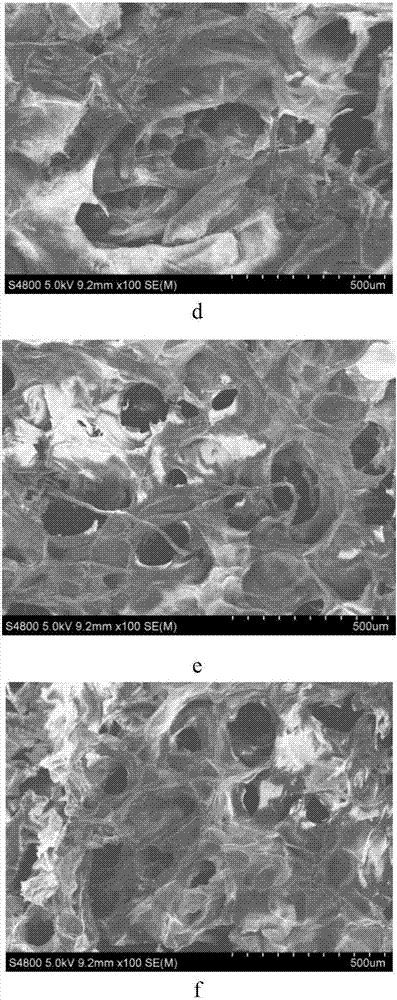

[0050] A certain amount of the six cellulose / acrylamide double-network hydrogel materials prepared in Example 1 was dried in a constant temperature drying oven at 60° C. to a constant weight, and the mass value was recorded. Place the weighed materials in beakers filled with deionized water, and weigh the mass value of the material at intervals of time until the mass value of the material tends to be stable. Calculate the swelling rate of the material at different time points, the results are as follows figure 2 shown. The final swelling rate of each material is shown in Table 1:

[0051] Table 1: Maximum Swelling Rates for Cellulose / Acrylamide Materials

[0052]

[0053]

[0054] It can be seen from Table 1 that the swelling rate of the material decreases with the increase of the crosslinking amount. If the swelling rate is too high, the material will be broken; if the swelling rate is too small, the adsorption effect will not be very good. The best overall performa...

Embodiment 3

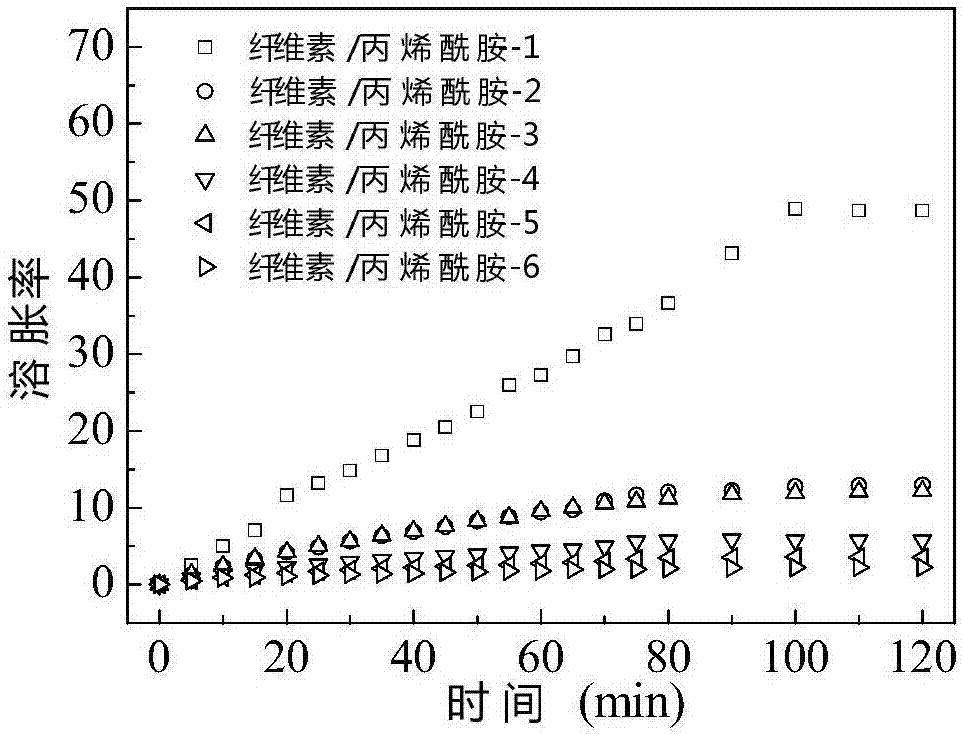

[0056] The six kinds of cellulose / acrylamide double network hydrogel materials without drying prepared in Example 1 were tested for compressive properties with a universal testing machine, and the stress-strain curves were as follows: image 3 shown. The turning point of stress drop in the figure is the breaking point of the material, and the corresponding deformation is the maximum deformation value of the material. The results show that all six materials have good mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com