Binary metal phosphide controlled by molybdenum trioxide (tungsten), preparation method and application

A binary metal, molybdenum trioxide technology, applied in the direction of electrodes, electrode shape/type, electrolysis process, etc., can solve problems such as unrealized, and achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Surface cleaning of nickel foam:

[0045] The nickel foam was immersed in 0.1 M dilute hydrochloric acid, and ultrasonically oscillated in an ultrasonic cleaner for 30 minutes to remove the dense NiO film on the surface; then it was ultrasonically cleaned in deionized water. Then ultrasonically cleaned in acetone; finally cleaned in absolute ethanol. The cleaned nickel foam was dried in a vacuum oven at 60 °C for 6 h.

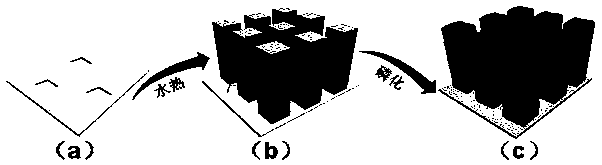

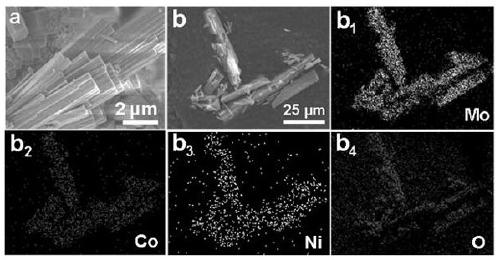

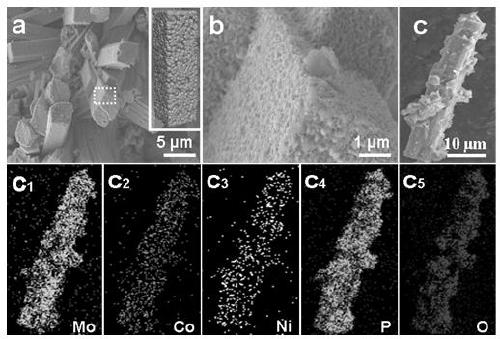

[0046] (2) Preparation of molybdenum-cobalt-nickel columnar precursor by hydrothermal method:

[0047] 0.002 M Ni(NO 3 ) 3 ·5H 2 O, 0.002 M Co(NO 3 ) 2 , 0.004 M Na 2 MoO 4 , 0.1 M NH 4 F was added to the reaction kettle, and magnetically stirred for 30 minutes to obtain a uniform solution; then, the cleaned foam nickel was added to the reaction kettle, and kept in an oven at 160°C for 10 hours; after natural cooling, a large amount of deionized water was used to Rinse off the remaining substances on the surface; dry in a vacuum oven at 60°C...

Embodiment 2

[0051] (1) Surface cleaning of nickel foam:

[0052] The nickel foam was immersed in 0.1 M dilute hydrochloric acid, and ultrasonically oscillated in an ultrasonic cleaner for 30 minutes to remove the dense NiO film on the surface; then it was ultrasonically cleaned in deionized water. Then ultrasonically cleaned in acetone; finally cleaned in absolute ethanol. The cleaned nickel foam was dried in a vacuum oven at 60 °C for 6 h.

[0053] (2) Preparation of tungsten-cobalt-nickel columnar precursor by hydrothermal method:

[0054] 0.002 M Ni(NO 3 ) 3 ·5H 2 O, 0.002 M Co(NO 3 ) 2 , 0.004 M Na 2 WO 4 , 0.1 M NH 4 F was added to the reaction kettle, and magnetically stirred for 30 minutes to obtain a uniform solution; then, the cleaned foam nickel was added to the reaction kettle, and kept in an oven at 160°C for 10 hours; after natural cooling, a large amount of deionized water was used to Rinse off the remaining substances on the surface; dry in a vacuum oven at 60°C fo...

Embodiment 3

[0058] (1) Surface cleaning of nickel foam:

[0059] The nickel foam was immersed in 0.1 M dilute hydrochloric acid, and ultrasonically oscillated in an ultrasonic cleaner for 30 minutes to remove the dense NiO film on the surface; then it was ultrasonically cleaned in deionized water. Then ultrasonically cleaned in acetone; finally cleaned in absolute ethanol. The cleaned nickel foam was dried in a vacuum oven at 60 °C for 6 h.

[0060] (2) Molybdenum-copper-nickel columnar precursor prepared by hydrothermal method:

[0061] 0.002 M Ni(NO 3 ) 3 ·5H 2 O, 0.002 M Cu(NO 3 ) 2 , 0.004 M Na 2 MoO 4 , 0.1 M NH 4 F was added to the reaction kettle, and magnetically stirred for 30 minutes to obtain a uniform solution; then, the cleaned foam nickel was added to the reaction kettle, and kept in an oven at 160°C for 10 hours; after natural cooling, a large amount of deionized water was used to Rinse off the remaining substances on the surface; dry in a vacuum oven at 60°C for 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com