Heterostructure material of hydrotalcite and carbon nanotube and its prepn process

A carbon nanotube and heterostructure technology is applied in the field of hydrotalcite/carbon nanotube heterostructure materials and their preparation to achieve the effect of uniform composite system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 3 g of carbon nanotubes with a length of 5-15 μm and a diameter of 40-60 nm and put them into a three-necked flask, add 100 ml of nitric acid with a concentration of 65%, heat and reflux for 6 hours, after the reflux is completed, cool to room temperature for suction filtration, and use deionized water Wash until neutral, then dry in an oven at 60° C. for 12 hours, and collect the modified carbon nanotubes.

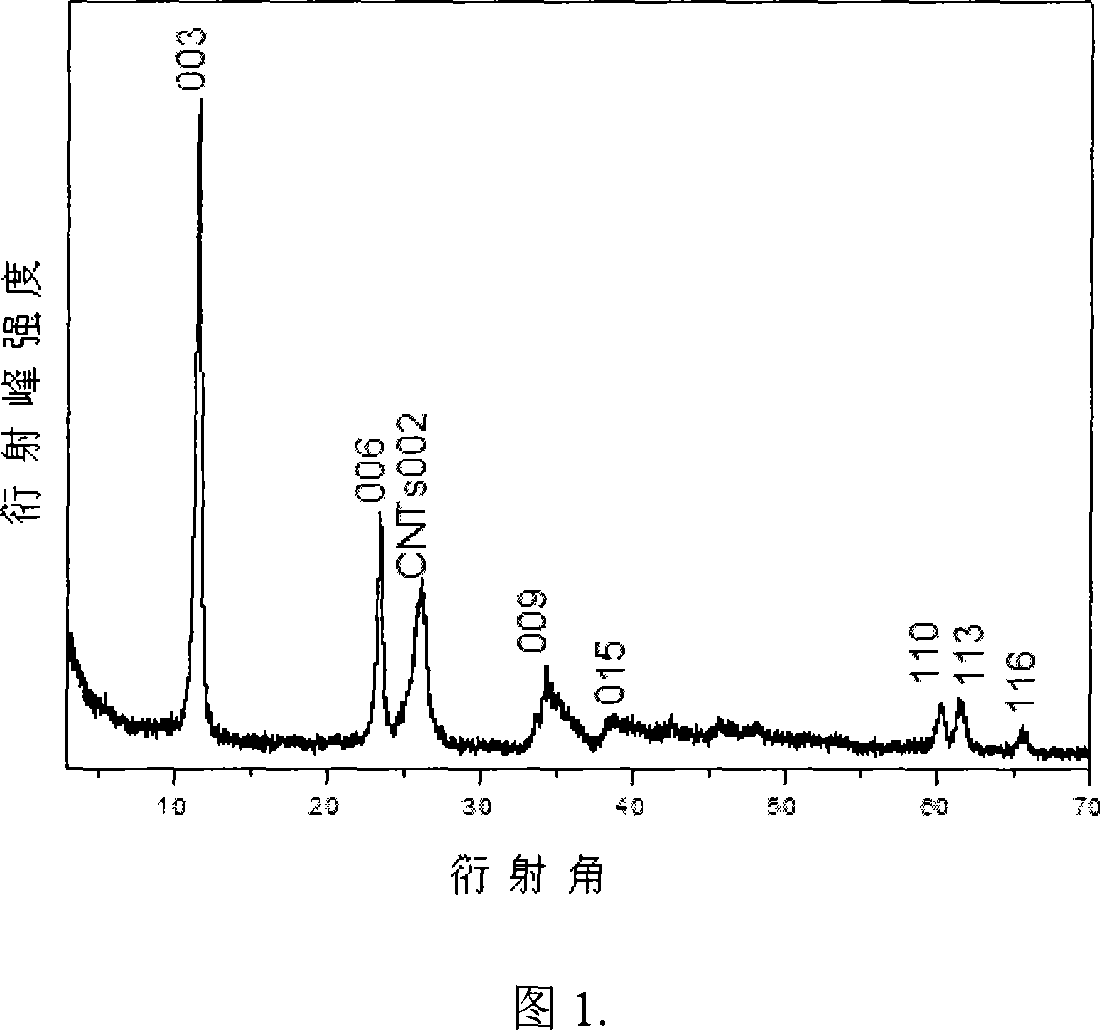

[0026] 4.3655g Co(NO 3 ) 3 ·6H 2 O and 1.8756g Al(NO 3 ) 3 9H 2 O was added to 100ml degassed deionized water to prepare a mixed salt solution, wherein Co(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 The molar concentrations of O are 0.15M and 0.05M respectively, and additionally 1.600g NaOH and 1.0599g NaOH 2 CO 3 Add to 100ml degassed deionized water to prepare a mixed alkaline solution, in which NaOH and Na 2 CO 3 The molar concentrations are 0.4M and 0.1M respectively. Pour the mixed alkaline solution into a four-necked flask, then add 0.5g of carbo...

Embodiment 2

[0029] Put 3 g of carbon nanotubes with a length of 5-15 μm and a diameter of 20-40 nm into a three-necked flask, add 100 ml of nitric acid with a concentration of 65%, heat and reflux for 8 hours, after the reflux is completed, cool to room temperature for suction filtration, and use deionized Wash with water until neutral, and then dry in an oven at 60° C. for 12 hours to collect the modified carbon nanotubes.

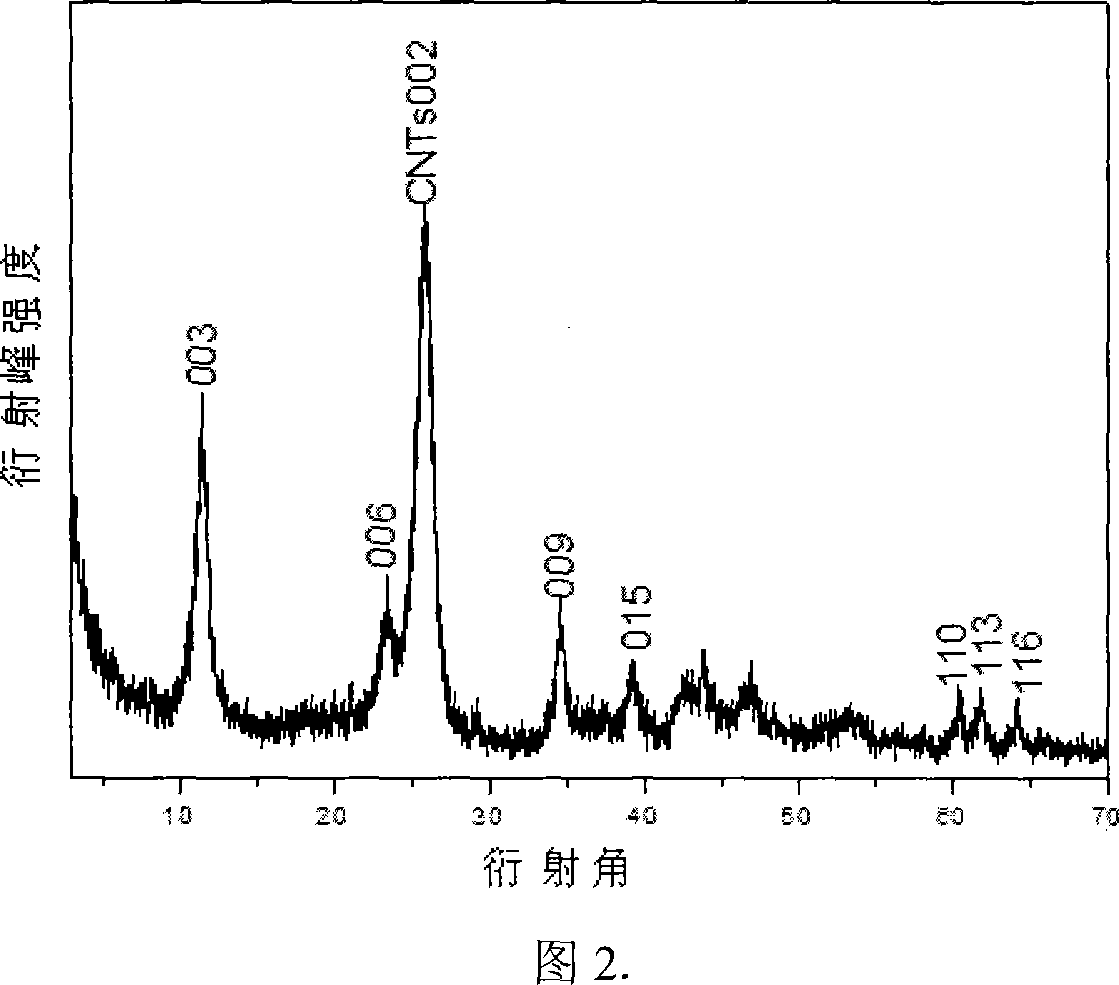

[0030] 9.3056g Ni(NO 3 ) 2 ·6H 2 O and 6.0021g Al(NO 3 ) 3 9H 2 O was added to 80ml degassed deionized water to prepare a mixed salt solution, wherein Ni(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 The molar concentrations of O are 0.4M and 0.2M respectively, and 3.840g NaOH and 2.7197g NaNO 3 Add to 80ml degassed deionized water to prepare a mixed alkaline solution, in which NaOH and NaNO 3 The molar concentrations are 1.2M and 0.4M respectively. Pour the mixed alkaline solution into a four-neck flask, add 1g of carbon nanotubes and 0.03mol of L-cysteine, stir at...

Embodiment 3

[0033] Put 2 g of carbon nanotubes with a length of 5-15 μm and a diameter of 20-40 nm into a three-neck flask, add 80 ml of nitric acid with a concentration of 65%, heat and reflux for 5 hours, after the reflux is completed, cool to room temperature for suction filtration, and use deionized Wash with water until neutral, and then dry in an oven at 60° C. for 12 hours to collect the modified carbon nanotubes.

[0034] 14.2620g NiCl 2 ·6H 2 O and 5.4060 g FeCl 3 9H 2 O was added to 100ml degassed deionized water to prepare a mixed salt solution, in which NiCl 2 ·6H 2 O, FeCl 3 9H 2 The molar concentrations of O are 0.6M and 0.2M respectively. In addition, 6.4000g NaOH and 2.3376g NaCl are added to 100ml degassed deionized water to prepare a mixed alkaline solution, wherein the molar concentrations of NaOH and NaCl are 1.6M and 0.4M respectively, Pour the mixed alkaline solution into a four-necked flask, add 0.8g of carbon nanotubes and 0.06mol of L-cysteine, stir at room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com