Method and equipment for processing wastewater of internal electrolysis based on supersound function

A technology for wastewater treatment and internal electrolysis, which is applied in water/sewage treatment, water/sludge/sewage treatment, mechanical oscillation water/sewage treatment, etc. It can solve problems such as clogging of reaction columns, and prevent rust, caking, and operating costs. Low, safe and convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

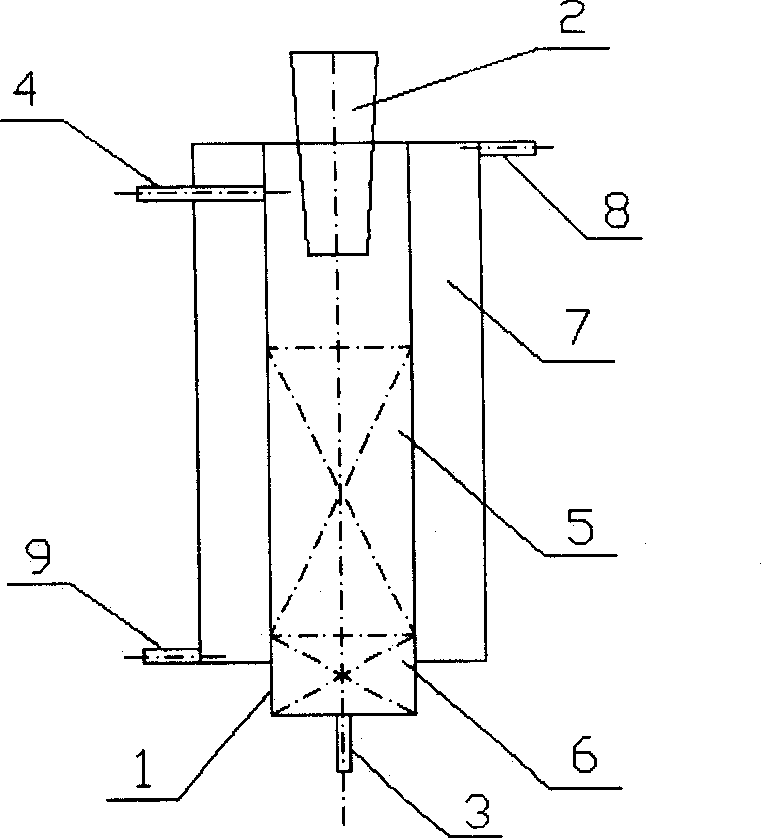

Image

Examples

Embodiment 1

[0017] Acid Orange II azo dye simulated wastewater, initial concentration 500mg / L, pH 4.03, the test device is a glass tube reactor with a diameter of 25mm. The flow rate of the treated water is 289ml / h, the ultrasonic power is 220W, the ultrasonic is 5 seconds, and the interval is 15 seconds. During the treatment time of 150 minutes, the average COD removal rate is 63.40%, the highest is 69.23%, and the average color removal rate is 77.19%. Up to 80.58%.

Embodiment 2

[0019] Acid orange II azo dye simulated wastewater, initial concentration 250mg / L, pH 3.97, treated water flow rate 291ml / h, ultrasonic power 80W, continuous ultrasonic, within 150min treatment time, the average COD removal rate is 54.49%, The highest is 72.46%, the average chroma removal rate is 79.40%, and the highest is 81.51%.

Embodiment 3

[0021] For a printing and dyeing wastewater, the initial COD=2000mg / L, pH4.03, the flow rate of the treated water is 266ml / h, the ultrasonic power is 220W, the ultrasonic is 5 seconds, the interval is 15 seconds, and the average COD removal rate is 56.26% in the treatment time of 150min , up to 60.33%, the average chroma removal rate is 67.954%, up to 74.23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com