Integrated structure for adsorption thermochemical energy-storage and building heating

A thermochemical and adsorption technology, applied in the field of thermochemical energy storage and building heating, can solve the problems of numerous pipeline structures, complex structures, high maintenance and operating costs, etc., to improve thermal efficiency, sufficient heat exchange, investment and maintenance. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

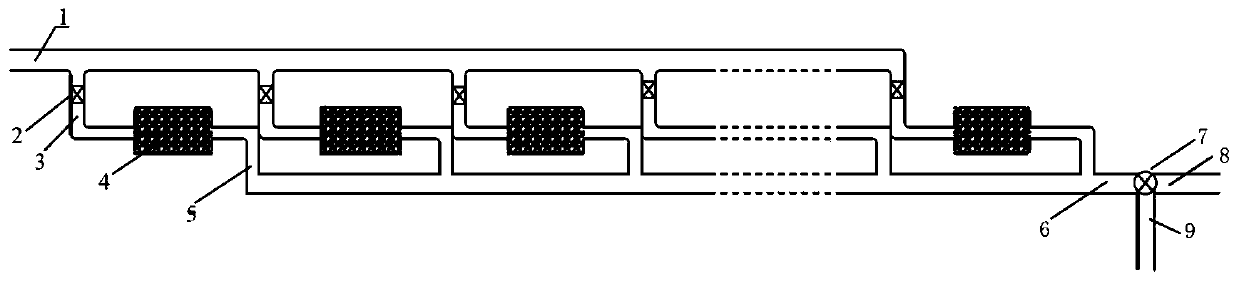

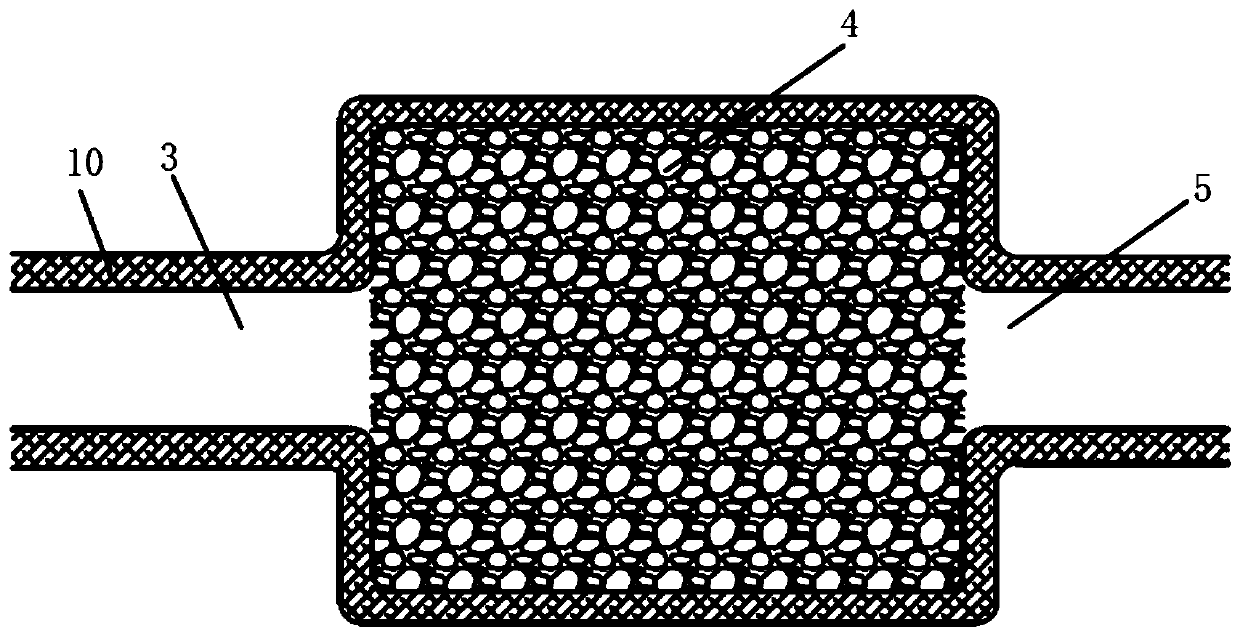

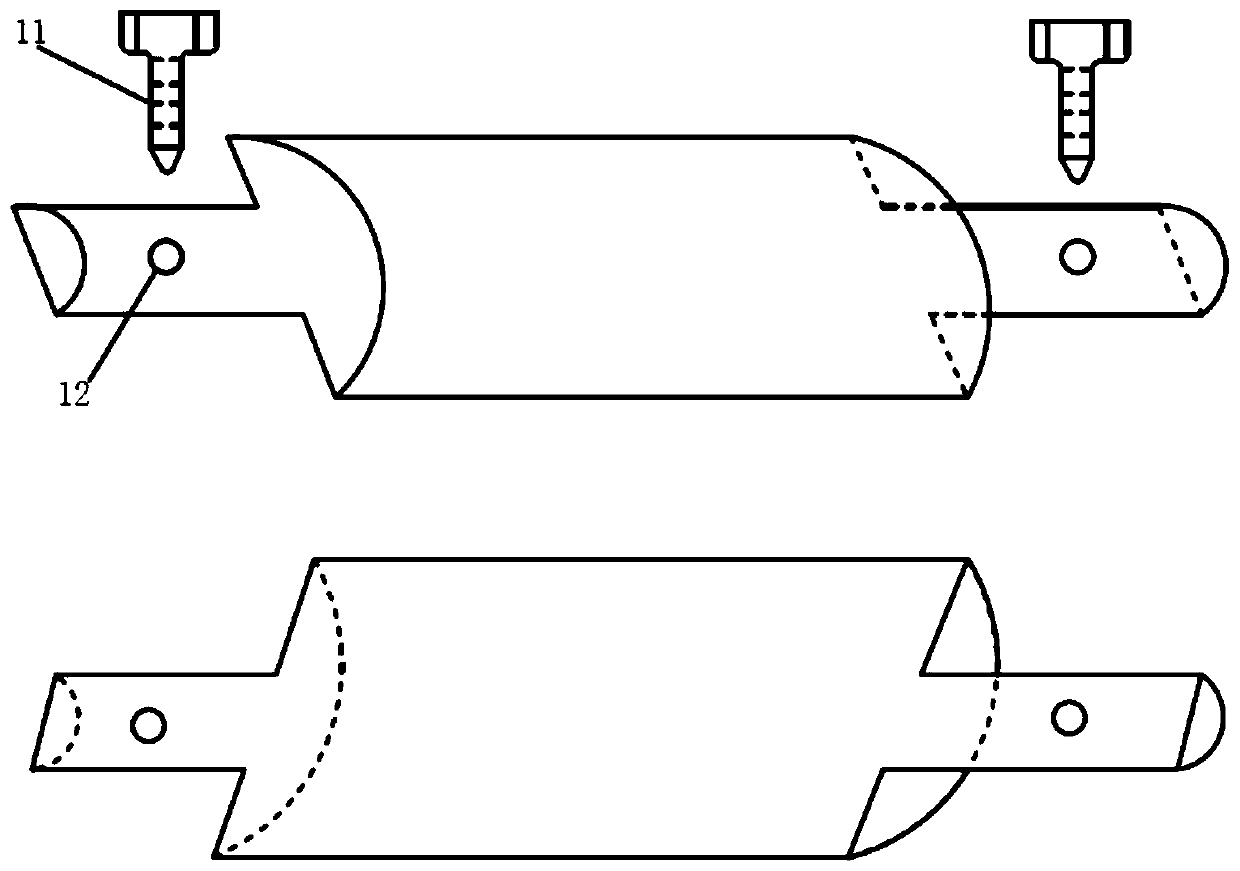

[0025] Such as figure 1 , figure 2 and image 3, an integral structure for adsorption thermochemical energy storage and building heating, including a gas main inlet 1, a valve 2, a gas inlet branch pipe section 3, an energy storage reaction bed 4, a gas outlet branch pipe section 5, and a gas main outlet section 6. Steering valve 7, gas outdoor outlet section 8, gas indoor outlet section 9, pipeline heat insulation layer 10, bolt 11, threaded hole 12. The gas inlet and outlet sections are both cylindrical pipes, and the general inlet section is used to connect the dry hot air or wet cold air pipes provided by the outside. The diameter of the reaction bed pipe connected to the gas branch pipe at both ends is not smaller than the diameter of the branch pipe. In order to improve the utilization rate of the incoming gas and ensure that the solid reactant reacts with the gas as much as possible, the diameter of the reaction bed pipe is 1 to 4 times the diameter of the branch pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com