Vapour-liquid two-phase flow accelerated corrosion test device

A flow-accelerated corrosion, vapor-liquid technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as the inability to understand the accelerated corrosion mechanism of vapor-liquid two-phase flow, and the fact that accelerated corrosion does not have guiding significance , to achieve the effect of excellent sealing characteristics and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

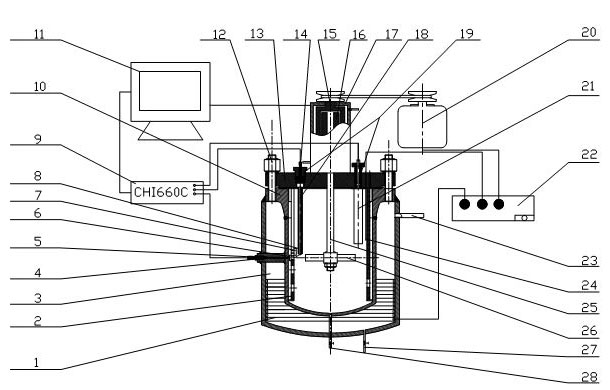

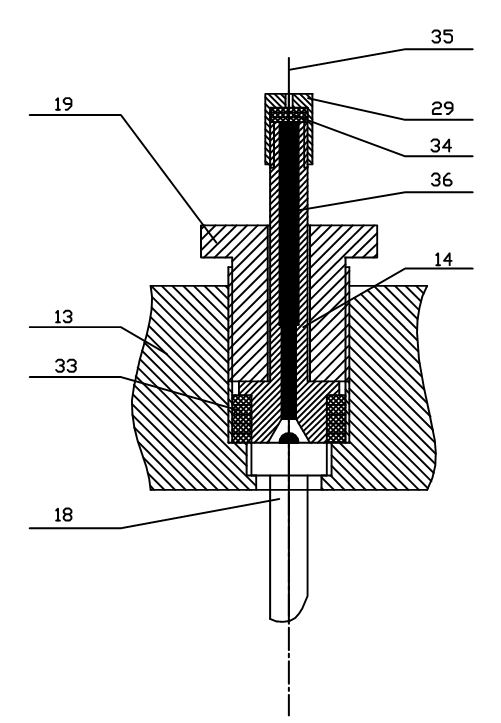

[0029] The present invention will be further described below in conjunction with accompanying drawing:

[0030] Such as figure 1, a device for vapor-liquid two-phase flow accelerated corrosion test, comprising a test kettle body 10, an oil bath heating jacket 3, a kettle body cover 13, a magnetic rotating device, a high-temperature reference electrode 18, a graphite auxiliary electrode 21, and a working electrode 6 , frequency conversion motor 20, potentiostat 9, corrosion measurement computer 11, equipment control box 22, inner liner 2, gas phase generator 7, electric heater 1 and thermocouple sensor 24, described test kettle body 10 and kettle body cover 13 is connected by bolt flange structure; the test kettle body 10 and the oil bath heating jacket 3 are welded by argon arc welding; the magnetic rotating device includes the outer magnetic drum 15 and the inner magnetic drum 16, and the electric heater in the oil bath heating jacket 1. The thermocouple temperature sensor 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com