Corrosion inhibitor for gas field and preparation method thereof

A corrosion inhibitor, oil and gas field technology, applied in earthwork drilling, wellbore/well components, organic chemistry, etc., can solve problems such as difficulty in adapting to corrosive environments, poor metal surface adsorption capacity and film formation, and increase activation energy Energy, Solubility Improvement, Effect of Corrosion Reaction Inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

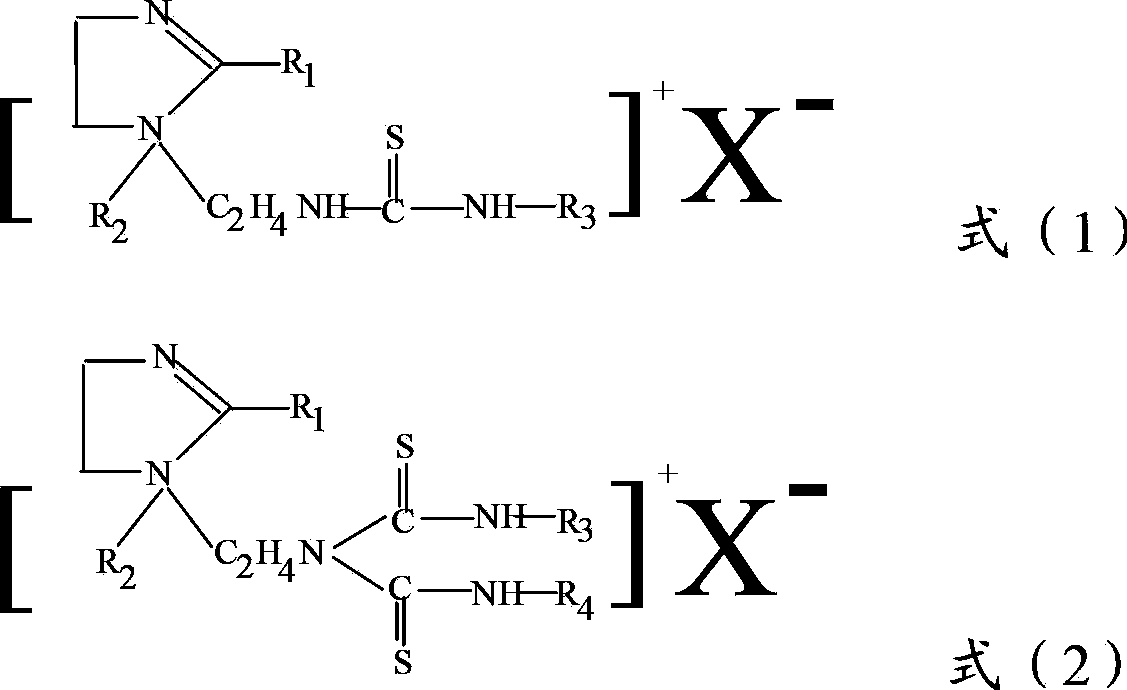

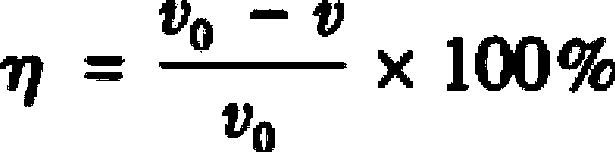

Method used

Image

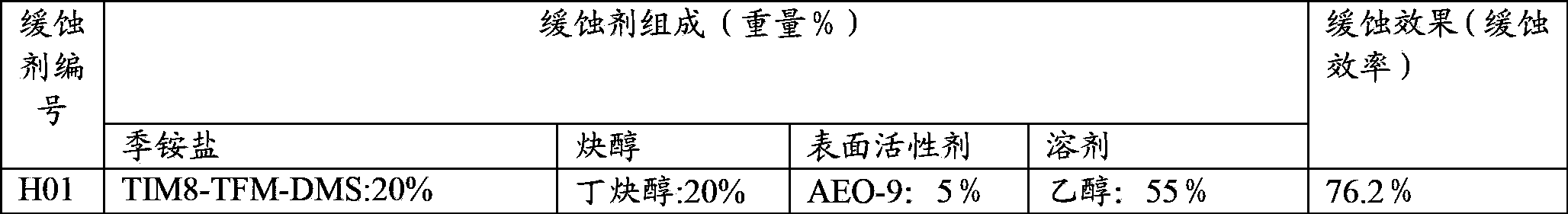

Examples

Embodiment 1

[0041] Step 1, prepare imidazoline intermediate:

[0042] Adding octanoic acid and diethylenetriamine with a molar ratio of 1:1.15 in a reactor with a stirring and distillation device, and adding water-carrying agent toluene, the weight of toluene is 50% of the total weight of octanoic acid and diethylenetriamine. The three are mixed evenly, heated to 145°C, reacted at 145°C for 3 hours, continued to heat up to 242°C, reacted at 242°C for 6 hours, cooled the reactant to 140°C, and distilled off the solvent toluene and unreacted Diethylenetriamine, after cooling, an imidazoline intermediate is obtained.

[0043] Step 2, preparation of thioureido imidazoline intermediate:

[0044]Dissolve the imidazoline intermediate obtained in step 1 in toluene, the weight of toluene accounts for 80% of the total weight of the two, and then add it to the reactor with a stirring and distillation device, raise the temperature to 100 ° C, and add sulfur to the reactor Urea, the molar ratio of i...

Embodiment 2

[0048] Step 1, step 2 are identical with step 1, step 2 of embodiment 1;

[0049] Step 3 is the same as step 3 of Example 1, the only difference is that benzyl chloride is used instead of dimethyl sulfate as a quaternization reagent to prepare the quaternary ammonium salt 1-benzyl-trifluoromethylsulfonylthiourea ethyl - 2-octyl imidazolinium ammonium chloride, represented by TIM8-TFM-CMB.

Embodiment 3

[0051] Step 1, step 2 are identical with step 1, step 2 of embodiment 1;

[0052] Step 3, preparation of fluorine-containing thiourea group imidazoline quaternary ammonium salt:

[0053] Dissolve the thioureidoimidazoline intermediate TIM8 in xylene, the weight of xylene accounts for 80% of the total weight of the two, and then add it to the reactor with a stirring and distillation device, raise the temperature to 110°C, and add perfluoro Butylsulfonyl fluoride, the molar ratio of intermediate TIM8 to perfluorobutylsulfonyl fluoride is 1:1.2, after 4 hours of reaction, after cooling, the fluorine-containing thioureido imidazoline intermediate 1-perfluorobutylsulfonylthiourea is obtained Ethyl-2-octyl imidazoline, represented by TIM8-PFB. Then slowly add the quaternary chemical reagent according to the molar ratio of TIM8-PFB and p-trifluoromethylbenzyl chloride 1:1.4. After the addition, react at 100°C for 5 hours. After cooling, the unreacted substance and the solvent are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com