Double-layer cooling pipe balanced forced cooling water cooling furnace mouth

A cooling tube and furnace mouth technology, applied in the field of metallurgical casting, can solve the problems of uneven distribution, the furnace mouth body cannot meet the cooling requirements, etc., and achieves the effects of improving distribution balance, cooling balance, and water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

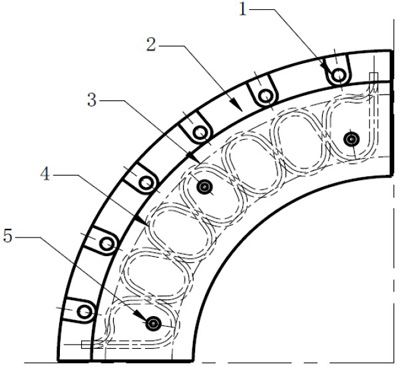

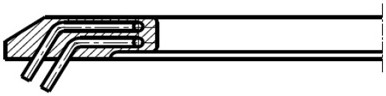

[0019] see figure 1 and figure 2 , the present invention provides a double-layer cooling tube balanced strong cooling water-cooled furnace mouth, which is mainly composed of a furnace mouth body 2 and a cooling pipe, and the upper and lower layers of cooling pipes are arranged in a dislocation and cross manner inside the furnace mouth body 2, respectively. Cooling pipe 3 and second cooling pipe 4.

[0020] The first cooling pipe 3 is arranged in a serpentine shape, and the first cooling pipe 3 forms an upper peak and a lower peak when the pipe is bent. The second cooling pipe 4 is also arranged in a serpentine shape, and the second cooling pipe 4 also forms an upper peak and a lower peak when the pipe is bent.

[0021] The first cooling pipe 3 and the second cooling pipe 4 are misplaced, that is, the first cooling pipe 3 and the second cooling pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com