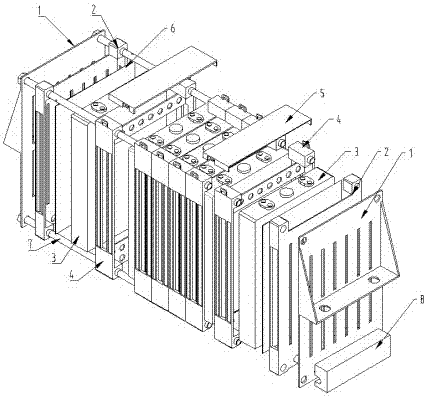

Square cell packing module

A prismatic battery and prismatic cell technology, applied in battery pack components, secondary batteries, circuits, etc., can solve the problems of high temperature of the battery pack system, affecting the performance of battery power and energy, and affecting battery safety and reliability, etc. Achieve the effect of improving heat dissipation balance, improving cycle efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the specific embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

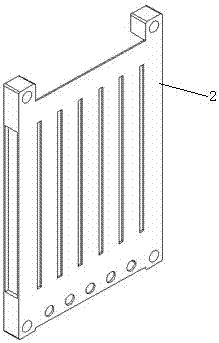

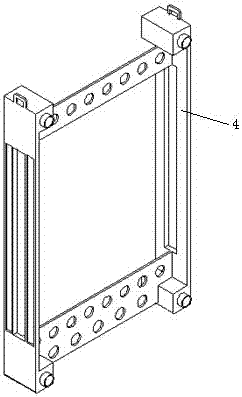

[0020] Such as figure 1 As shown, a grouping module of a square battery includes two fixed brackets 1 arranged at both ends, end brackets 2 are respectively arranged inside the fixed brackets 1, and a plurality of intermediate brackets 4 are arranged between the two end brackets 2; The end bracket 2 and the middle bracket 4 are sequentially connected by the long screw rod 7, and the two ends of the long screw rod 7 are respectively fixed on the fixed bracket 1; the square battery core 3 is respectively fixed between the middle bracket 4 and the end bracket 2 , one side of the square cell 3 is pasted with a heat-conducting silica gel sheet 6; the square cell 3 is provided with a cover plate 5; it also includes a heat sink 8, and the heat sink 8 includes a plurali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com