Manufacturing method of mirror surface oriented silicon steel with good magnetic performance and annealing parting agent

A technology for annealing separator and oriented silicon steel, applied in the field of annealing separator and mirror oriented silicon steel manufacturing, it can solve the problems of limited core loss effect, unstable secondary recrystallization, surface corrosion of steel plate, etc., and achieve excellent magnetic properties and punching. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment.

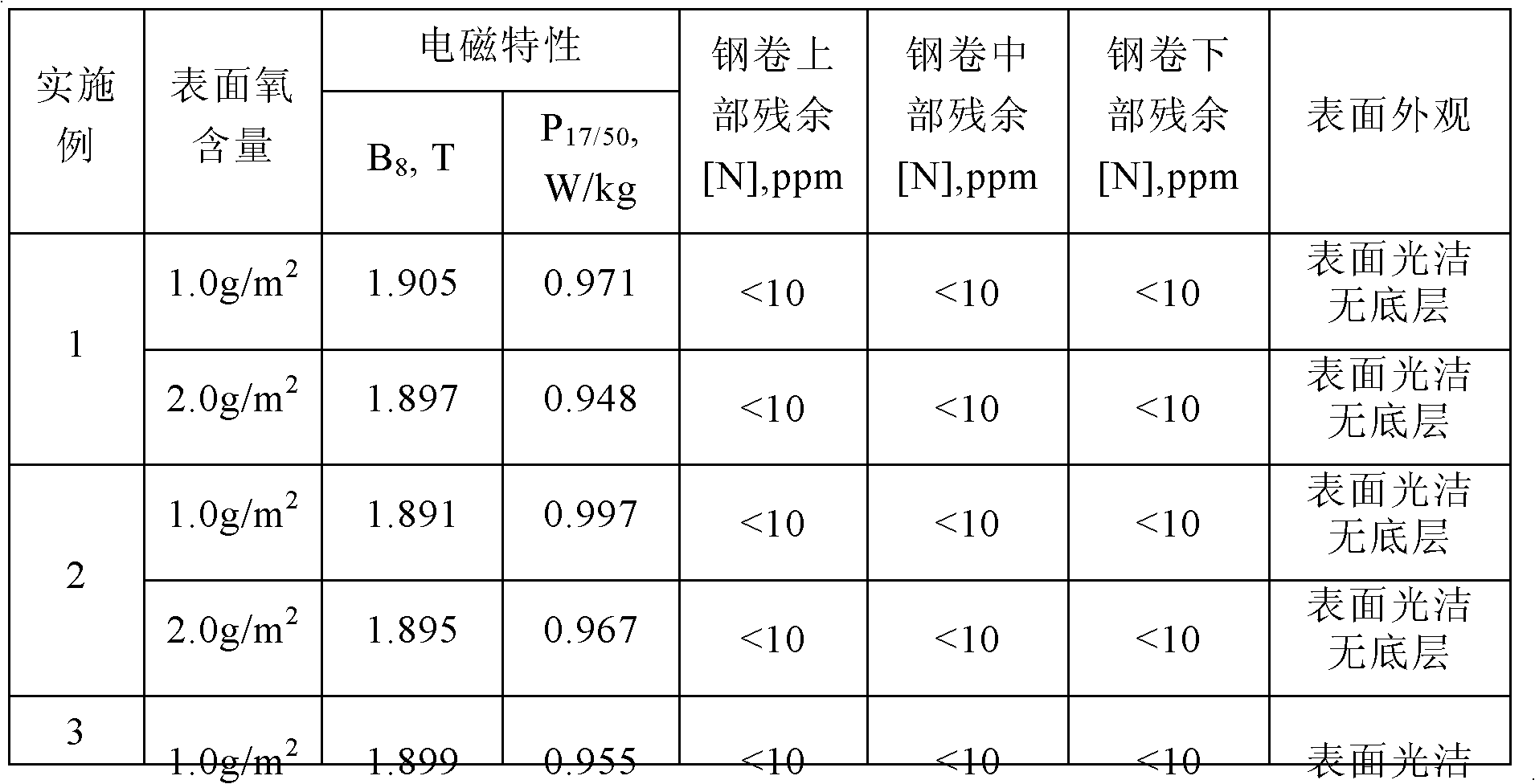

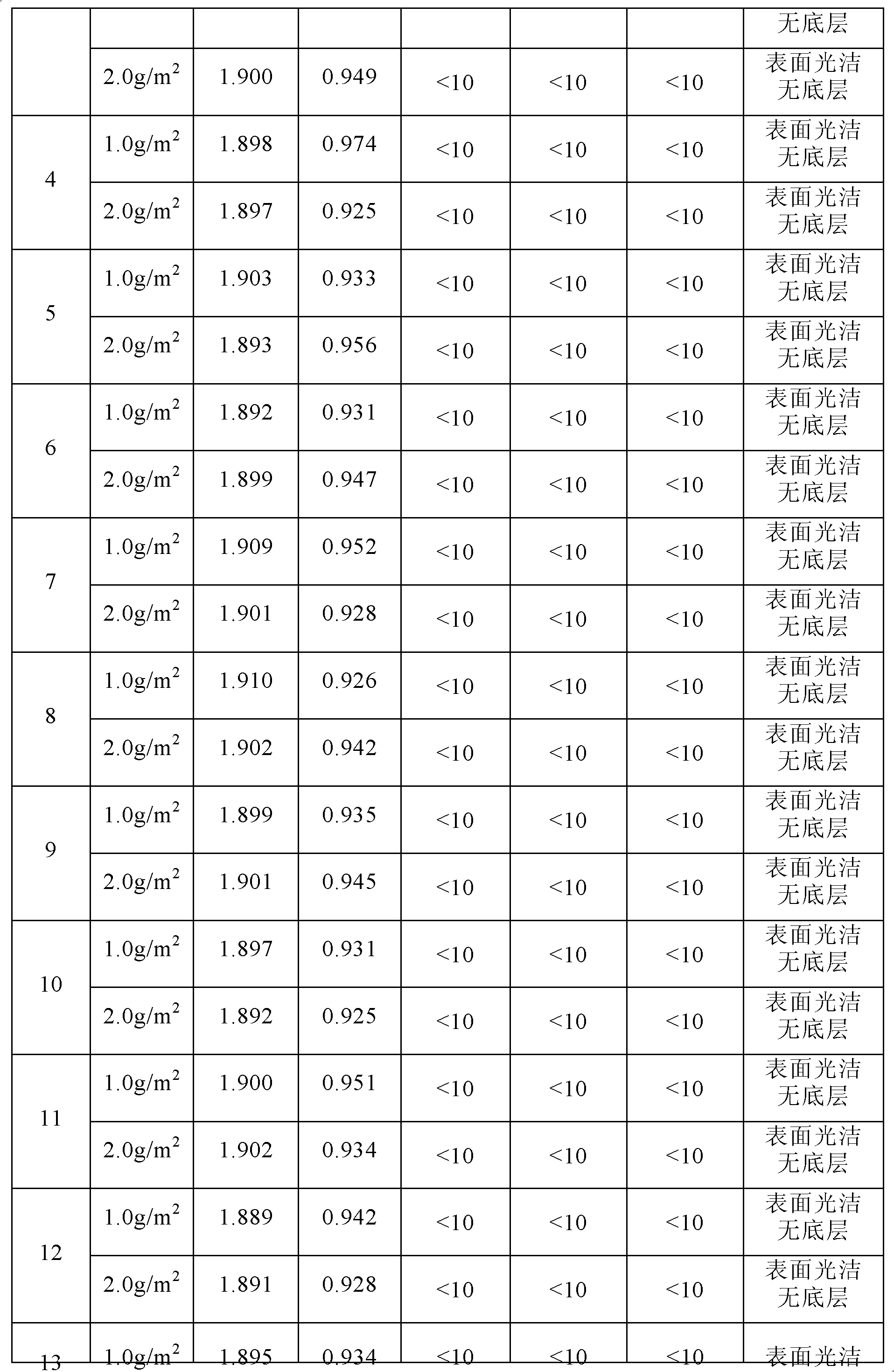

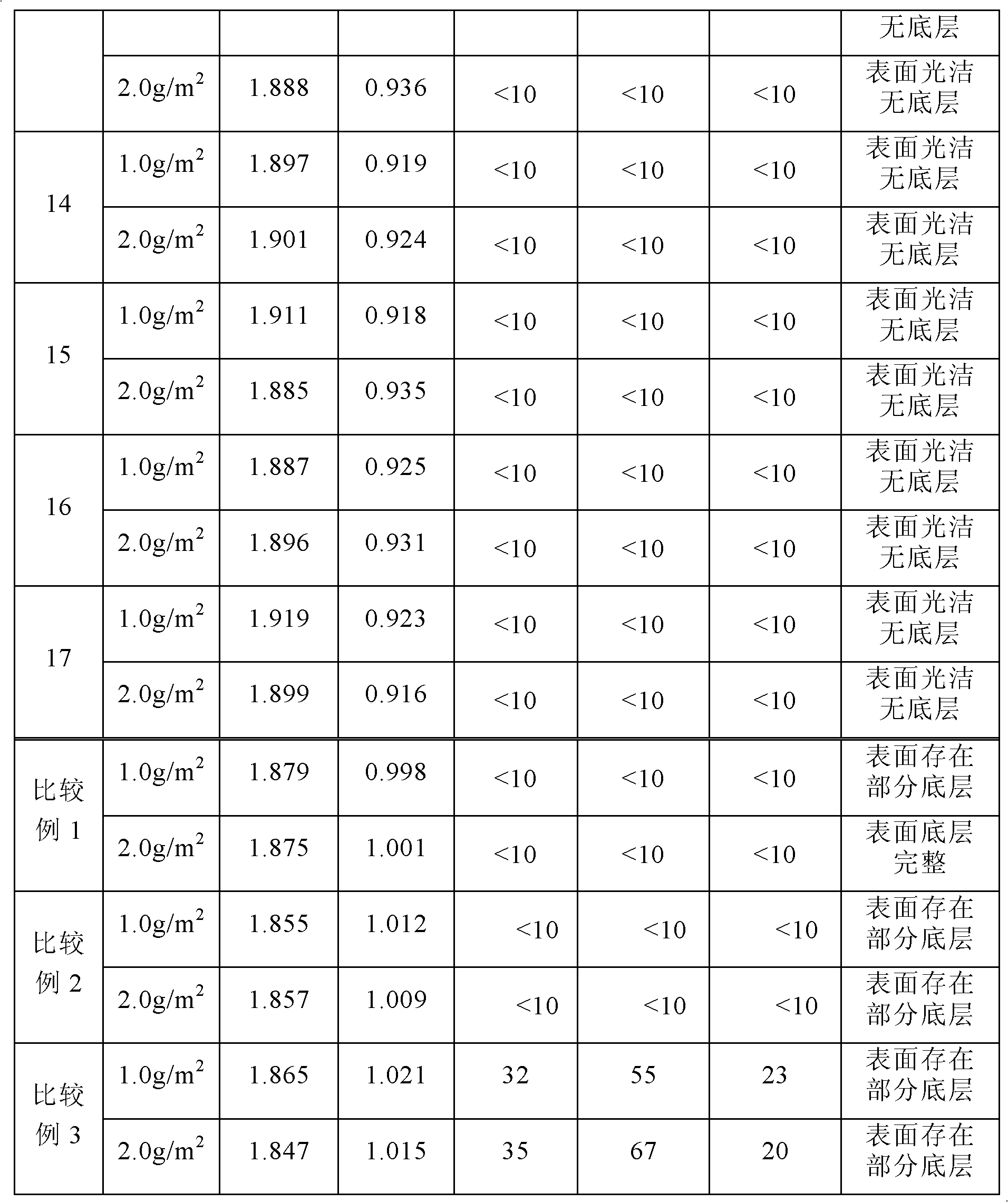

[0031] Using a 500kg vacuum furnace to make steel, the chemical composition (wt%) of the slab is: 0.045%C, 3.25%Si, 0.006%S, 0.027%Als, 0.006%N, 0.15%Cu, 0.012%Mn, the rest is Fe and unavoidable of impurities. After the billet is heated at 1150°C, it is hot-rolled into a hot-rolled plate with a thickness of 2.6mm. After the hot-rolled sheet is normalized and annealed at 1150°C for 1 minute, it is pickled and cold-rolled to a final sheet thickness of 0.285 mm. The cold-rolled sheet is decarburized and annealed at 835°C for 120 seconds, and the surface oxygen content is 1.0 and 2.0g / m 2 Two levels; after nitriding treatment, the nitrogen content of the steel plate is 250ppm. The decarburized annealed sheet is coated with annealing release agent, and the composition ratio is shown in Table 1. After coiling, it is annealed at 1200°C and held for 20 hours in a dry nitrogen and hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com