Acid corrosion solution for preparing multicrystal silicon pile surface and its using method

一种酸腐蚀、多晶硅的技术,应用在化学仪器和方法、表面浸蚀组合物、半导体/固态器件制造等方向,能够解决废水处理成本高、重金属环境污染危害比较大等问题,达到消除环境的危害的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

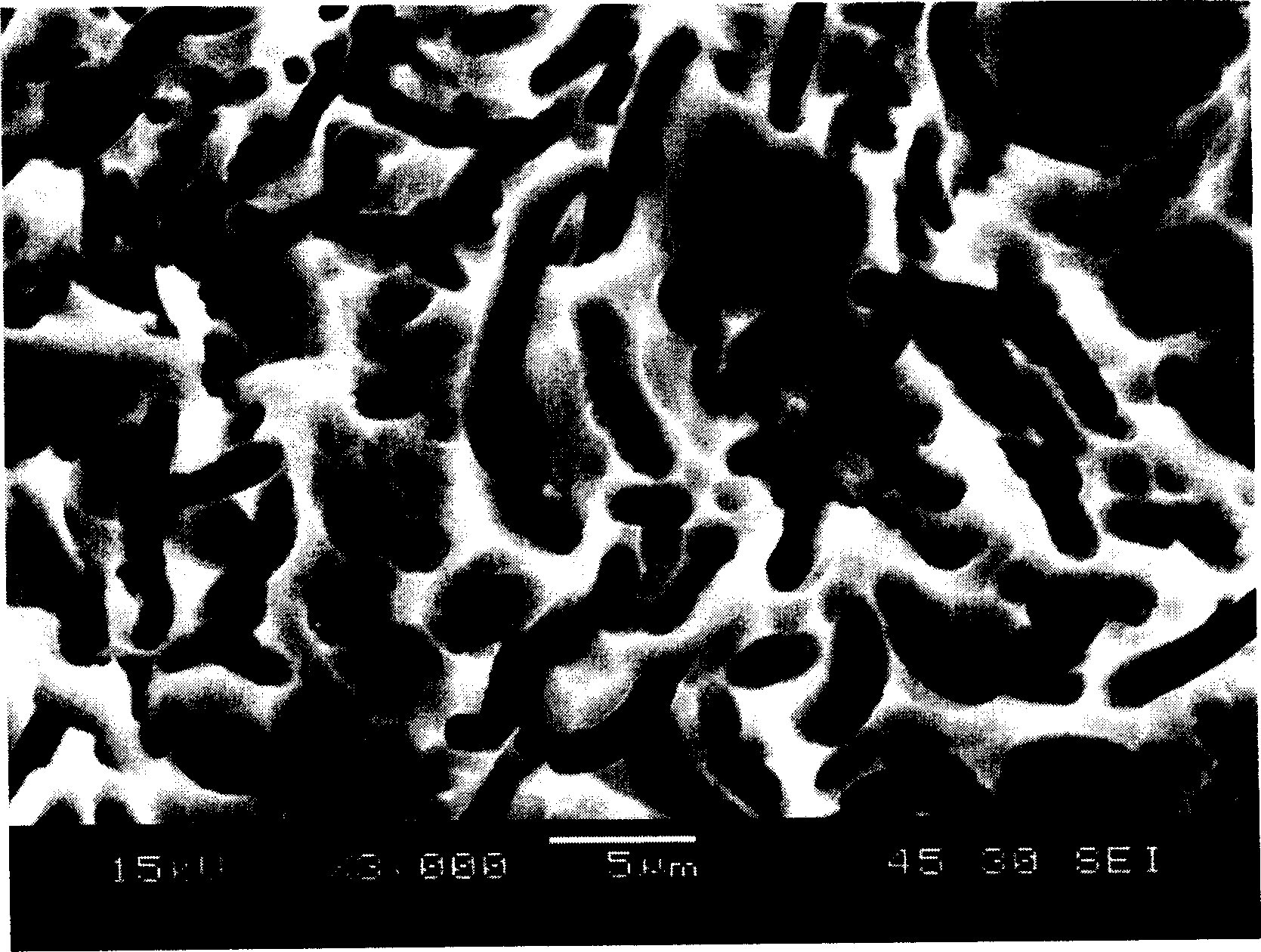

[0016] Add 5 moles of KNO3 to the hydrofluoric acid solution with a concentration of 20 moles / liter, mix well, control the temperature of the solution at 20 degrees, put it into a 125*125 polysilicon wafer cut by wire cutting, and corrode it for 10 minutes. This polycrystalline silicon wafer is then made into a solar cell. The conversion efficiency, fill factor, open circuit voltage and current of the solar cell are 14.49%, 0.765, 598 millivolts and 4.95 amperes, respectively. The surface morphology of the etched polysilicon is shown in Figure 1.

Embodiment 2

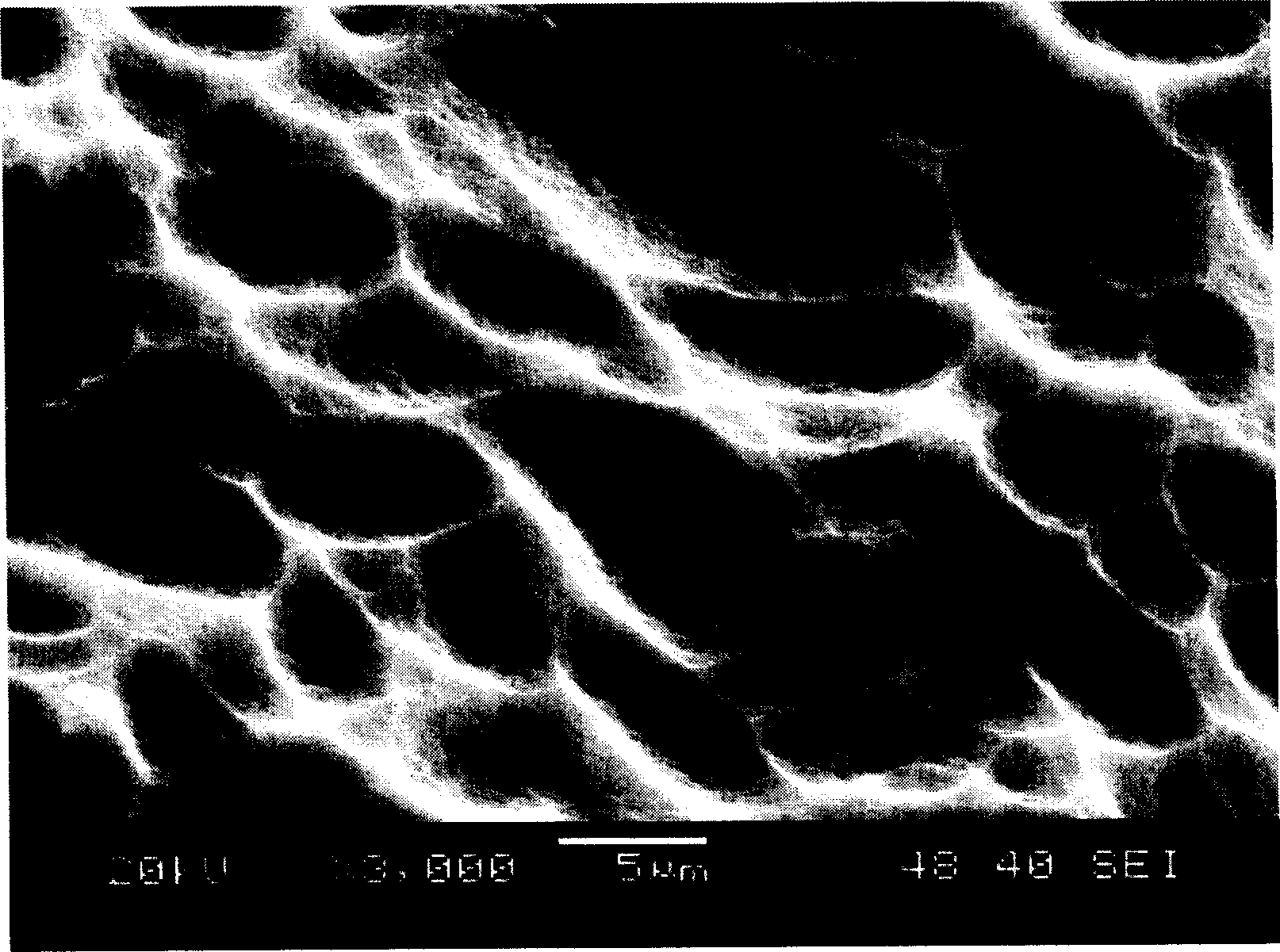

[0018] Add 2.34 moles of NH4NO2 to 1 liter of 20 mol / liter hydrofluoric acid, mix well, control the temperature of the solution at -10 degrees, put in a 125*125 polysilicon wafer, and etch for 20 minutes. This polycrystalline silicon wafer is then made into a solar cell. The conversion efficiency, fill factor, open circuit voltage and current of this solar cell are 15.38%, 0.768, 611 millivolts and 5.12 amperes, respectively. The surface morphology of the etched polysilicon is shown in Figure 2.

Embodiment 3

[0020] Add 1.17 moles of NaNO3 to 1 liter of 20 moles / liter of hydrofluoric acid, mix well, control the temperature of the solution at 10 degrees, and then add 0.15 moles of NaNO2. Put in a 125*125 polysilicon wafer and etch for 20 minutes. This polycrystalline silicon wafer is then made into a solar cell. The conversion efficiency, fill factor, open circuit voltage and current of this solar cell are 15.03%, 0.771, 608 millivolts and 5.01 amperes, respectively. The surface morphology of the etched polysilicon is shown in Fig. 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com