Production method of environmental friendly plasticizer DOTP and production system

An environmentally friendly plasticizer and production method technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid esters, etc. Cost saving, reducing equipment corrosion, improving the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

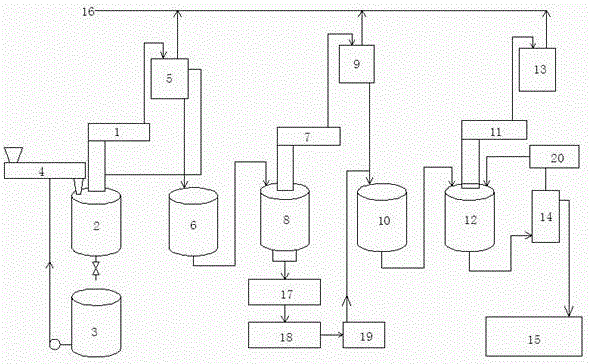

[0029] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises the esterification dealcoholization still 2 that installs the first condenser 1, and the double-screw meter 4 that is connected octanol tank 3 is installed on the top of described esterification dealcoholization still 2, and the first condenser 1 is separated by alcohol water Device 5 connects buffer tank 6, and buffer tank 6 connects the still 8 that installs second condenser 7, and second condenser 7 connects decolorization kettle 10 by first recovery tank 9, and decolorization kettle 10 connects the deodorization that installs the 3rd condenser 11 Kettle 12, the third condenser 11 is connected to the second recovery tank 13 and the bottom of the deodorization kettle 12 is connected to the filter 14, and the filter 14 is connected to the finished product tank 15; the alcohol-water separator 5, the first recovery tank 9 and the second recovery tank 13 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com