Lithium sulphur battery anode piece added with absorbent and lithium sulphur battery

A positive pole piece, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of cycle performance degradation, battery capacity attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

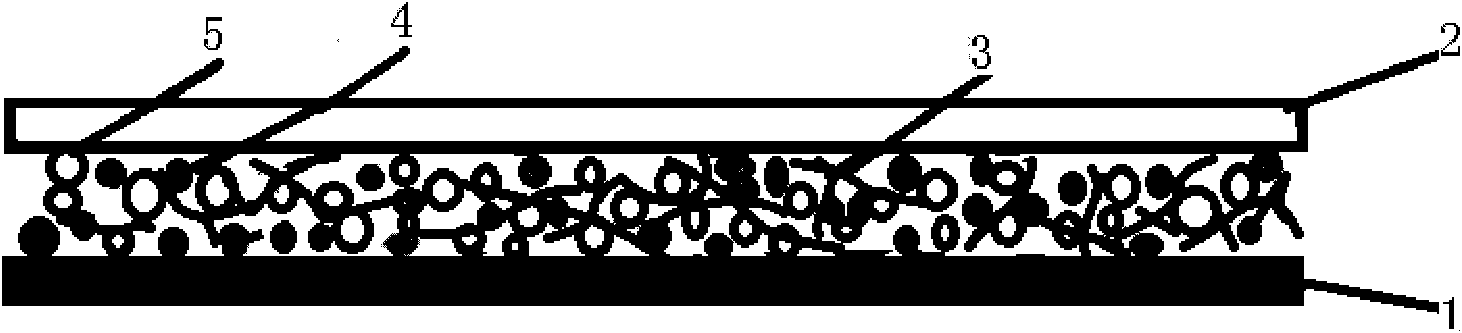

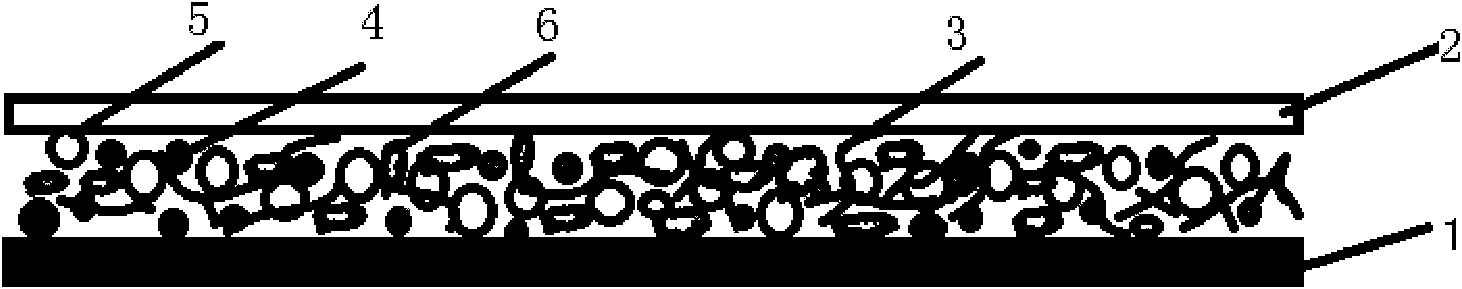

Method used

Image

Examples

Embodiment 1

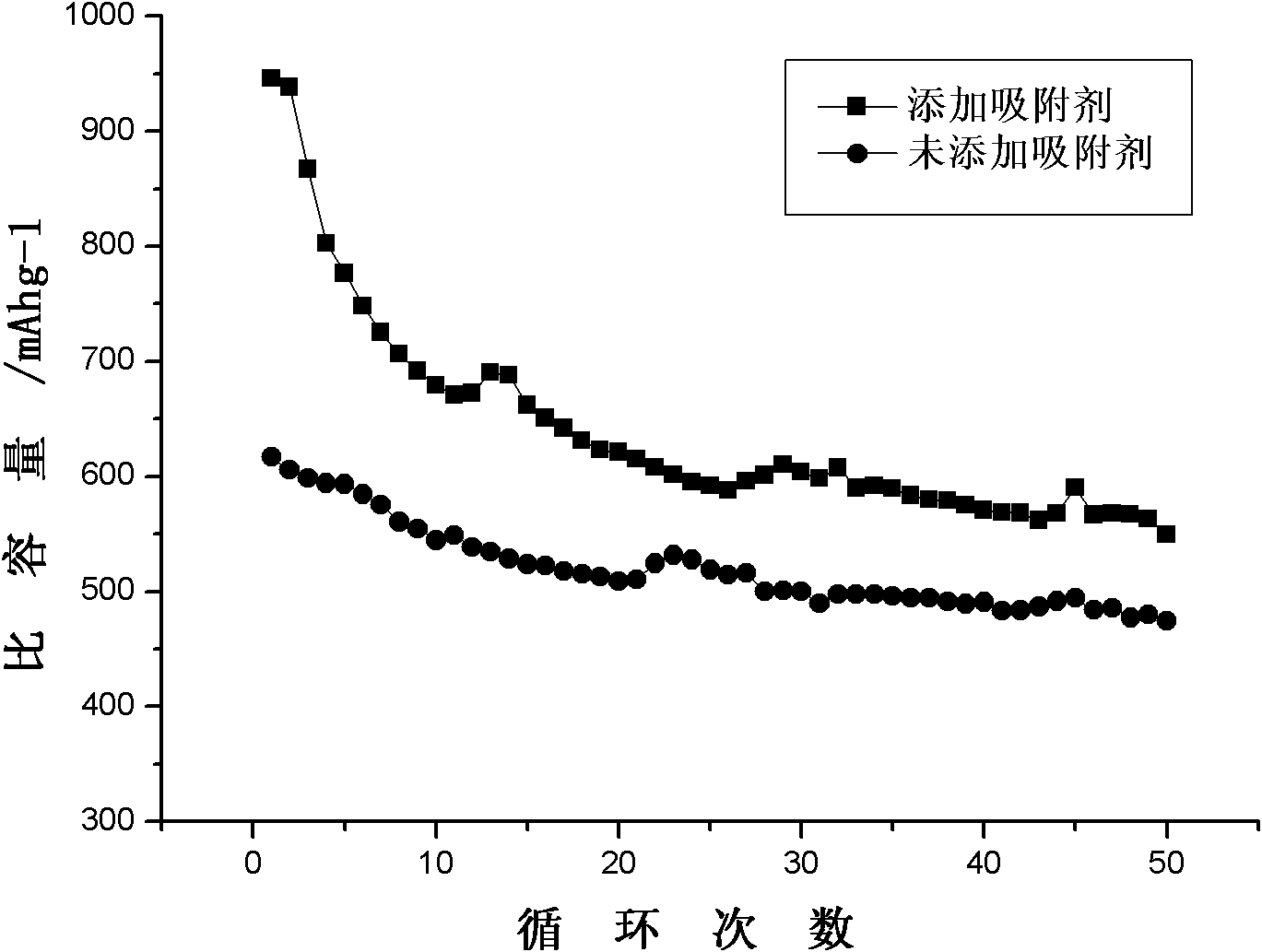

[0024] The selected specific surface area is 1000m 2 The active carbon of / g is made adsorbent, and adsorbent accounts for 15% by mass percentage in positive electrode material, and positive electrode active material is carbon nanotube and sulfur composite material, and acetylene black is made conductive agent, and the PVDF (polyvinylidene fluoride) of 5wt% The solution (the solvent is NMP, N-methylpyrrolidone) is used as a binder to prepare the positive electrode slurry; then the slurry is coated on the foamed nickel to prepare a positive electrode sheet, and dried to obtain the required positive electrode sheet, the positive electrode The thickness of the pole piece is 45-55um. Select Celgard2400 film as the battery diaphragm to assemble the battery, the electrolyte is 1mol / L LiPF6 / EC:DMC:EMC (1:1:1 volume ratio, EC: ethylene carbonate, DMC: dimethyl carbonate, EMC: carbonic acid methyl ethyl ester), and the entire battery assembly process was completed in a glove box.

[...

Embodiment 2

[0027] Activated carbon and sulfur composite materials are selected as the positive electrode active material, and porous carbon microspheres are used as the adsorbent material to prepare the positive electrode sheet. The conductive agent is superconducting carbon black BP2000, and the mass ratio of the positive electrode active material, conductive agent, binder and adsorbent is 60%: 15%: 15%: 10%. Prepare the positive electrode sheet and assemble the battery by the same method as in Example 1. The battery charge and discharge test results show that the first charge and discharge specific capacity of the material is 867.4mAh / g, and the specific capacity after 50 cycles is also maintained at 535.6mAh / g. Good battery performance was shown.

Embodiment 3

[0029]A composite material of carbide-derived carbon and sulfur (wherein the pore size distribution of carbide-derived carbon is 0.5-5nm) is selected as the positive electrode active material, and mesoporous carbon is used as the adsorbent material to prepare the positive electrode sheet, wherein the positive electrode active material, conductive agent, binder The mass ratio of agent and adsorbent is 75%:10%:10%:5%. The same method as in Example 1 was used to prepare the positive electrode sheet and assemble the battery. The charge-discharge test results show that the initial charge-discharge specific capacity of the material is 924.1mAh / g, and the specific capacity remains at 607.9mAh / g after 50 cycles, showing good battery performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com