Lithium ion battery full charge storage service life evaluation method

A lithium-ion battery, charge storage technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of increased storage temperature, low data reliability, and long evaluation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

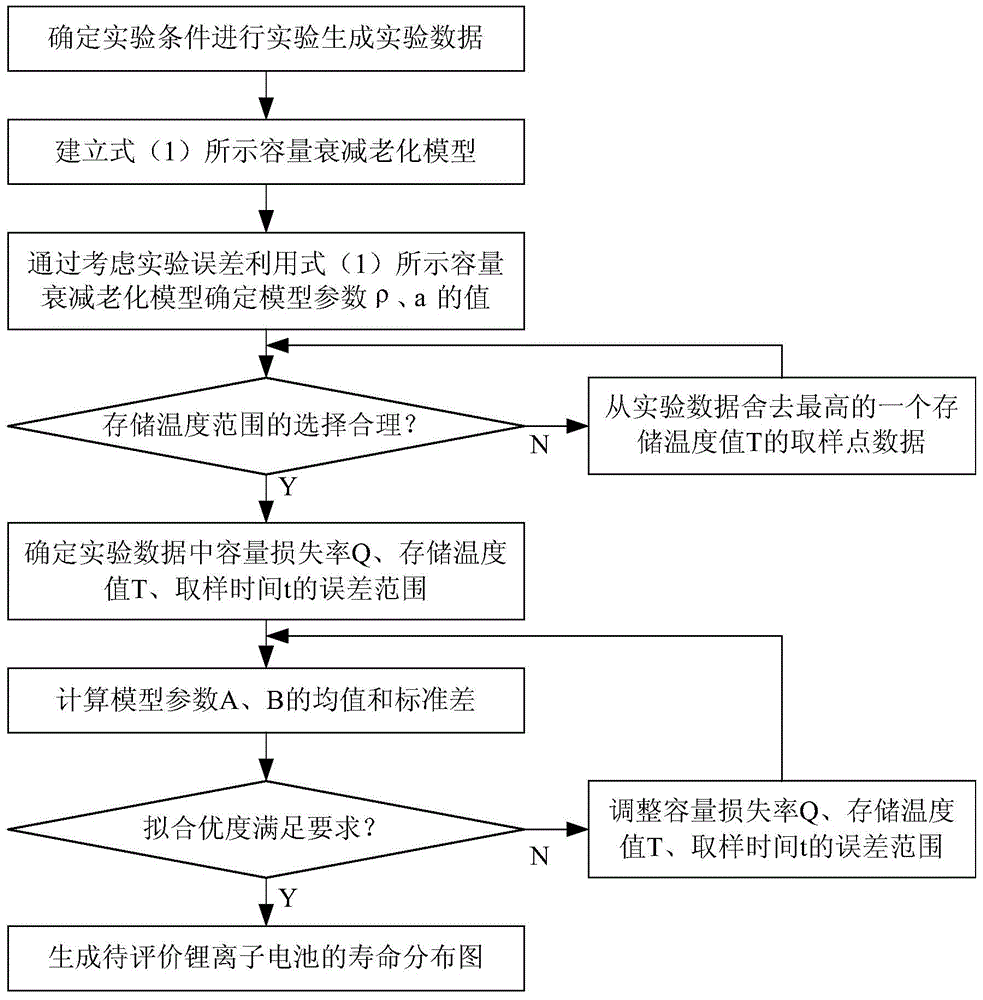

[0059] like figure 1 As shown, the steps of the lithium-ion battery full charge storage life evaluation method in this embodiment include:

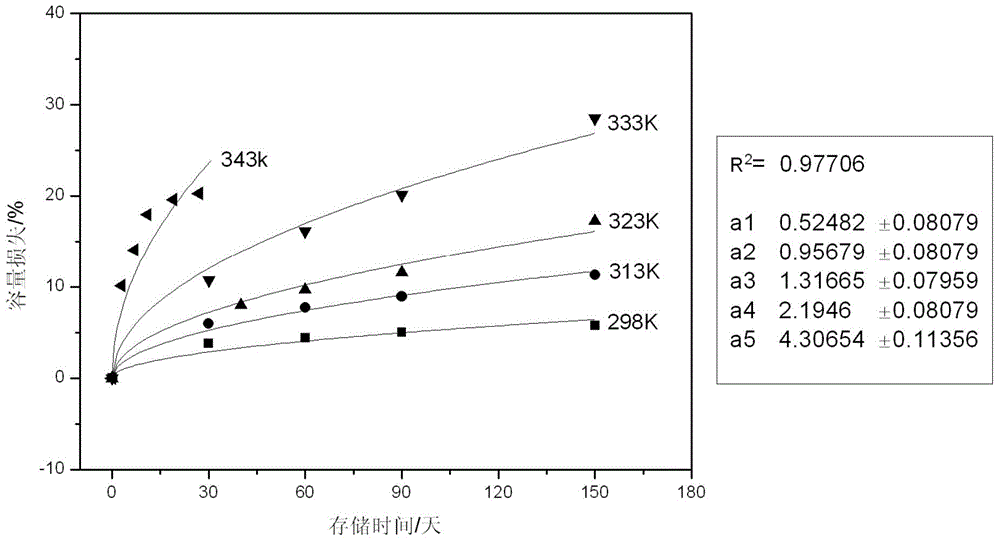

[0060] 1) Determine the experimental conditions and conduct experiments to generate experimental data: determine the storage temperature range according to the lowest storage temperature of the lithium-ion battery to be evaluated and the electrolyte decomposition temperature, and select multiple storage temperature values T according to the preset temperature interval within the storage temperature range, Store the battery sample for evaluating the full charge state of the lithium-ion battery for a specified sampling time t under multiple storage temperature values T, and each sampling time t under each storage temperature value T is used as a sampling point, and each sampling point corresponds to For at least one battery sample, obtain the capacity loss rate Q of the battery sample at each sampling point to generate experimental data...

Embodiment 2

[0107] The basic steps of this embodiment are the same as that of Embodiment 1, and its main difference is:

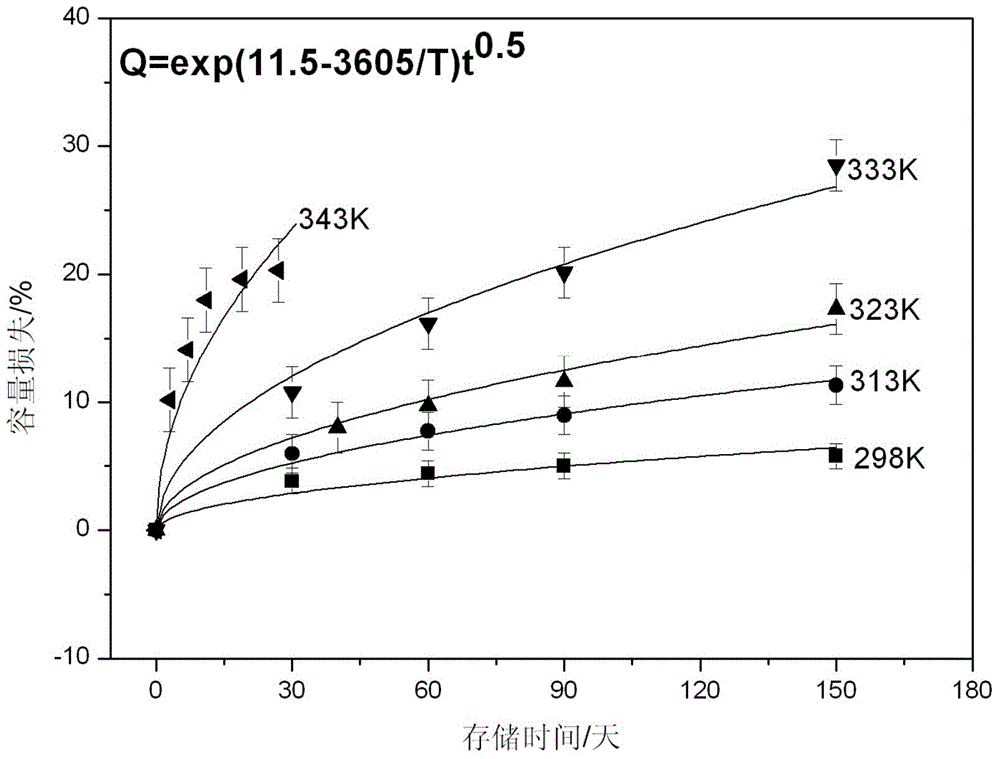

[0108] In step 1) of this embodiment, in view of the fact that the capacity of the battery in this example decays too quickly at 343K at the initial stage of the experiment, the highest acceleration temperature adopted in this example is 333K, the interval temperature interval is 5K, and four interval temperature intervals are taken, so the storage Set the temperature as 298K, 318K, 323K, 328K, 333K, and set the sampling time as 15 days, 30 days, 45 days, 60 days, 90 days. At the same time, due to the large difference in the capacity of the single cells of the battery in Example 2, the number of samples was increased to 5, and the final test plan for each sampling point was finally obtained as shown in Table 4. In addition, the capacity of the experimental data was also included in this example. The error ranges of loss rate Q, storage temperature value T, and sampling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com