Multifunctional annular oil-gas-water multiphase flow corrosion simulation test device

A simulation test, oil, gas and water technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problem that rigid pipes cannot realize arbitrary inclination angle transformation, cannot reflect pipeline circumferential corrosion, and cannot realize pressure-bearing pipelines, etc. problem, to achieve the effect of simple and reliable loop design, helpful for control and measurement, and convenient and free supplementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

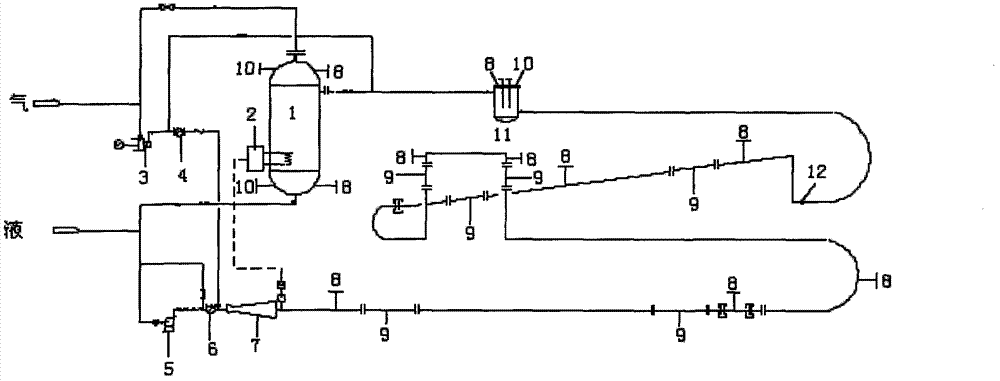

[0025] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings.

[0026] A multifunctional loop type oil-gas-water multiphase flow corrosion simulation test device, including a control cabinet, a gas-liquid separator 1, an electric heater 2, a gas booster 3, a gas flowmeter 4, a screw pump 5, and a liquid flowmeter 6. Static mixer 7, corrosion detection probe 8, rotatable joint, corrosion detection pipe section 9, corrosion hanger 10 and corrosion reaction kettle 11. It is characterized in that both the gas source pipeline and the gas outlet pipeline of the gas-liquid separator are connected to the inlet of the gas booster, and a control valve is arranged on the gas outlet pipeline of the gas-liquid separator, and the outlet pipeline of the gas booster is connected to the horizontally arranged static The inlet of the mixer is connected, the outlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com