Backheating gas mixed circulating refrigeration, heating and temperature adjustment system

A technology of gas mixing and temperature adjustment system, which is applied in the direction of temperature control by electric means, which can solve the problems of high cooling capacity consumption, high heating power consumption, and uneconomical heating and cooling rate, so as to increase the heating and cooling rate and improve the use environment , The effect of reducing energy consumption and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

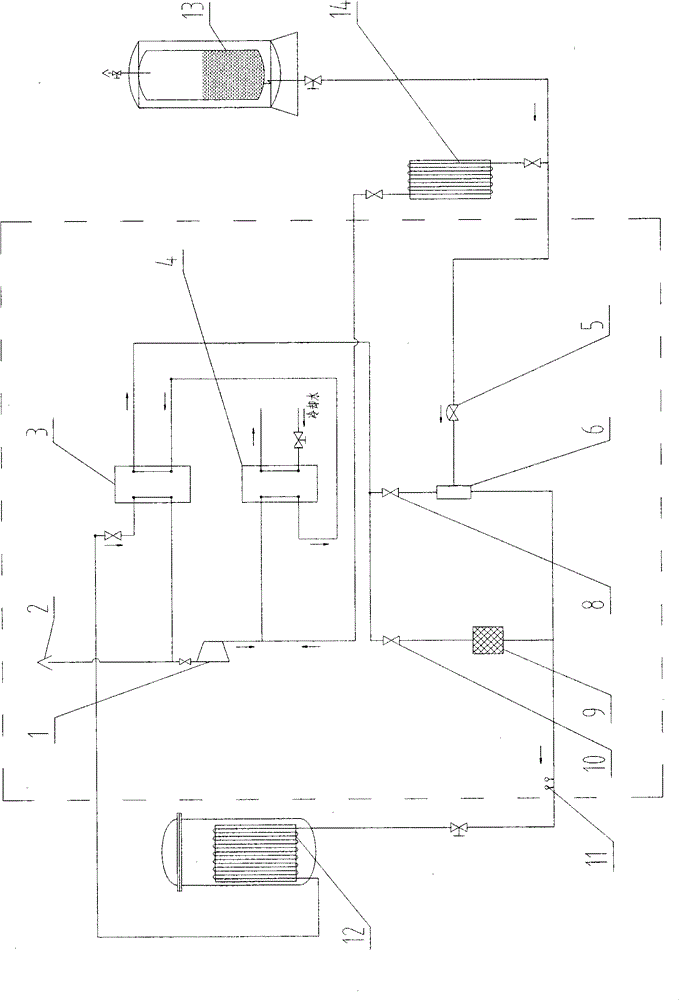

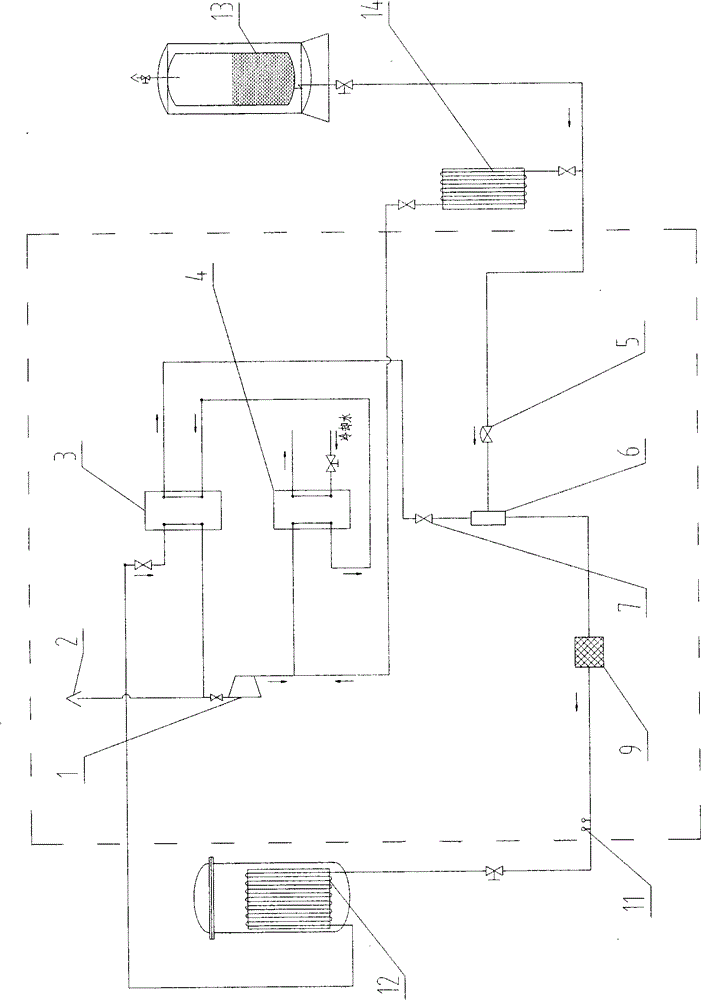

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0048] The components of the system are: circulation fan 1, exhaust port 2, two-channel regenerator 3, water-cooled heat exchanger 4, liquid nitrogen flow control valve 5, liquid nitrogen mixer 6, general stop valve 7, heating stop valve 10 And refrigeration stop valve 8, heater 9, sensor 11, heat sink (or other temperature-controlled structure) 12, liquid nitrogen storage tank 13, vaporizer 14 and the pipelines connecting the above functional components.

[0049] In the parallel connection mode of liquid nitrogen mixer and heater, if attached figure 1 Shown:

[0050] The heat sink (or other temperature-controlled structure) 12 is a device that requires temperature control in the process of the present invention, and the process provides a temperature-controlled circulating gas for the heat sink. as attached figure 1 As shown, the inlet of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com