High-anti-yellowing silicon rubber compound and preparation method thereof

A technology of raw silicone rubber and silicone rubber, applied in the field of silicone rubber, can solve the problems of affecting the appearance of the product, the effect is not particularly obvious, restricting the application of silicone rubber, etc., to achieve the effect of expanding the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of aforementioned high anti-yellowing silicone rubber compound, comprises the following steps:

[0024] 1) Put the silicone rubber raw rubber, hydroxy silicone oil, zinc stearate, release aid, hydrogen-containing silicone oil and anti-yellowing additive pyrophosphoric acid in the aforementioned parts by weight into a kneader and stir for 5-10 minutes, then divide Add white carbon black in batches and knead into a dough. After kneading evenly, raise the temperature to 150-180°C, banbury for 0.5-4h at a vacuum degree of 0.05-0.07MPa, and finally cool down to below 80°C and filter to obtain silicone rubber. glue;

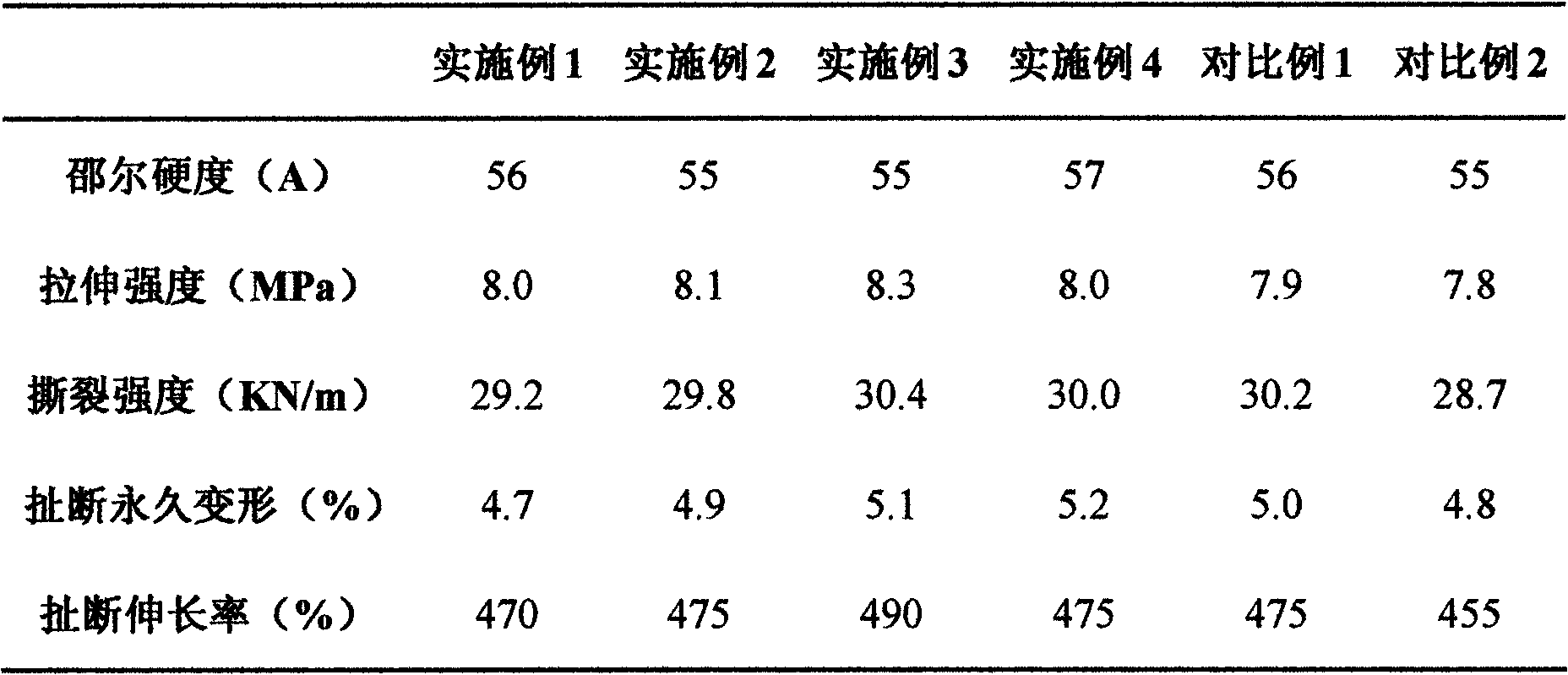

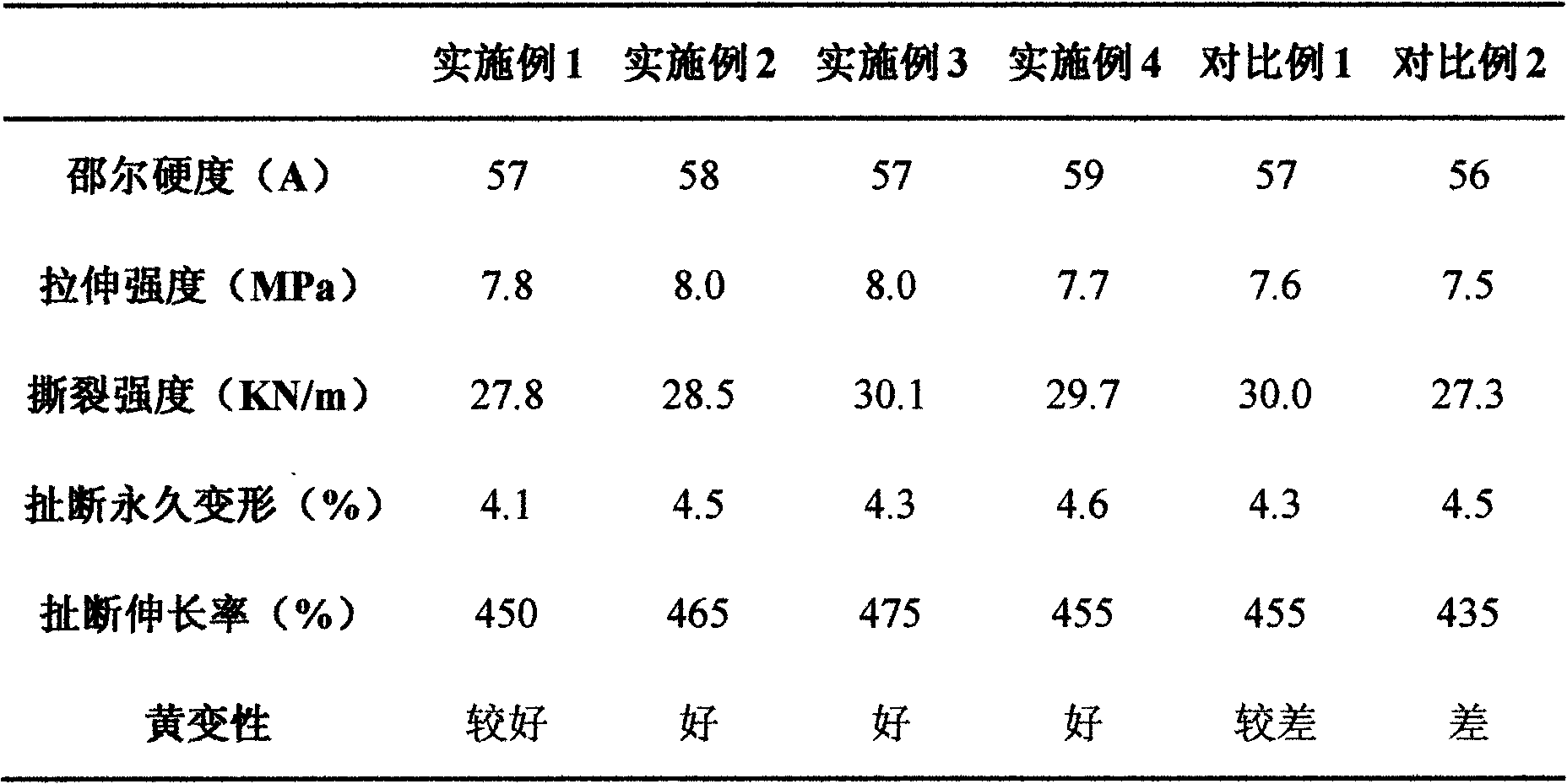

[0025] 2) Let the above-mentioned mixed rubber stand still, then add a vulcanizing agent to the open mill for reverse milling, and then carry out one-stage vulcanization and two-stage vulcanization, and measure the mechanical properties of the first-stage vulcanization and two-stage vulcanization of the silicone rubber compound accor...

Embodiment 1

[0027] Example 1: The average degree of polymerization is 10000, the vinyl content is 100 parts by weight of methyl vinyl raw rubber of 0.22 mol%, 9 parts of hydroxyl silicone oil, 0.5 part of zinc stearate, 3 parts of hydrogen-containing silicone oil and anti-yellowing Pyrophosphoric acid (concentration: 600-800ppm) 0.01 part of the auxiliary agent is put into the kneader and stirred for 5-10 minutes at a time, and then added in 40 parts by mass in three times. The specific surface area (BET method) is at least 150m 2 / g of fumed silica is kneaded into agglomerates, and after kneading evenly, start to heat up, and when the temperature of the rubber material rises to about 160°C, start vacuuming, keep the vacuum within 0.05-0.07MPa, banbury for 0.5-4h, after the vacuum is over When the temperature is lowered to below 80°C, the material is discharged, filtered, and packaged to obtain a rubber compound.

[0028]100 parts by weight of this silicone rubber compound, mix and disper...

Embodiment 2

[0029] Example 2: the average degree of polymerization is 10000, the vinyl content is 100 parts by weight of methyl vinyl raw rubber of 0.22 mol %, 9 parts of hydroxyl silicone oil, 0.5 part of zinc stearate, 3 parts of hydrogen-containing silicone oil and anti-yellowing Pyrophosphoric acid (concentration: 600-800ppm) 0.05 parts of the auxiliary agent is put into the kneader for 5-10 minutes at a time, and then added in 40 parts by mass in three times. The specific surface area (BET method) is at least 150m 2 / g of fumed silica is kneaded into agglomerates, and after kneading evenly, start to heat up, and when the temperature of the rubber material rises to about 160°C, start vacuuming, keep the vacuum within 0.05-0.07MPa, banbury for 0.5-4h, after the vacuum is over When the temperature is lowered to below 80°C, the material is discharged, filtered, and packaged to obtain a rubber compound. In the same manner as in Example 1, the vulcanization test was carried out on the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com