A continuous flow reactor

A reactor and reaction tube technology, applied in the field of continuous flow reactors, can solve the problems of large reactor volume, poor turbulent flow effect, and low Reynolds coefficient, and achieve the effects of improving turbulent flow effect, simplifying installation and assembly, and improving reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

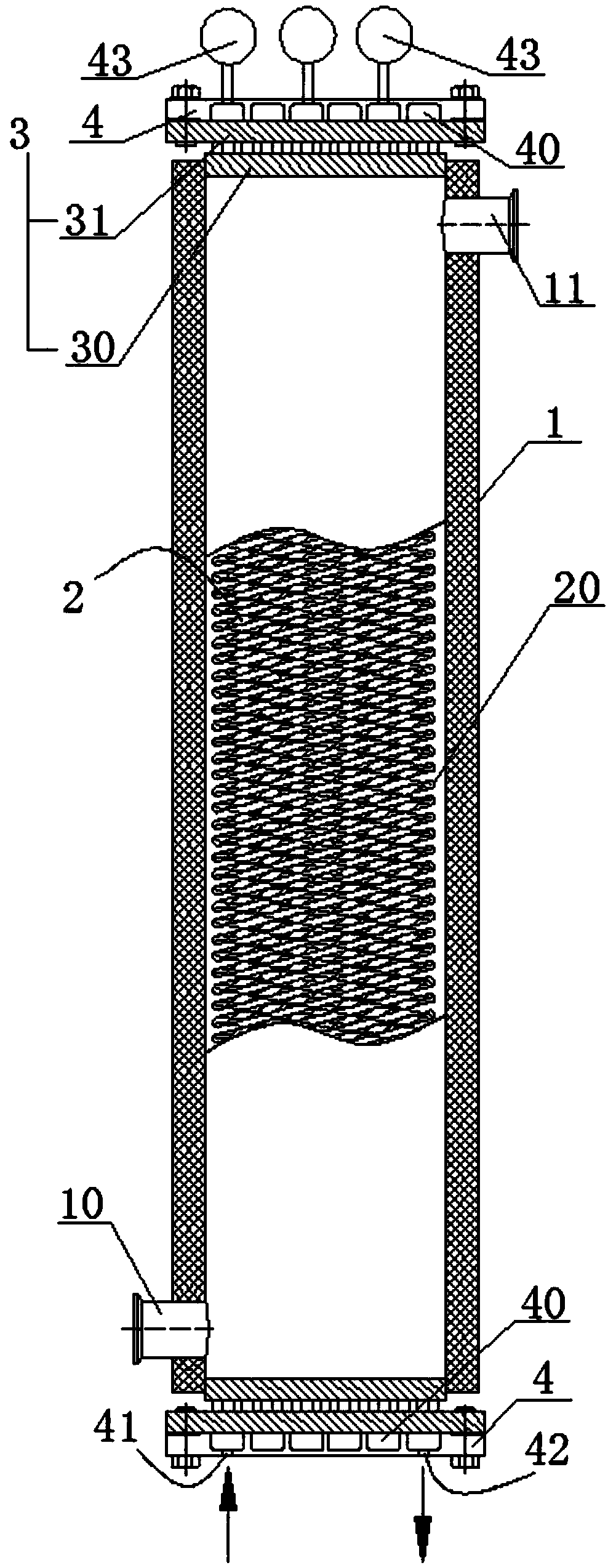

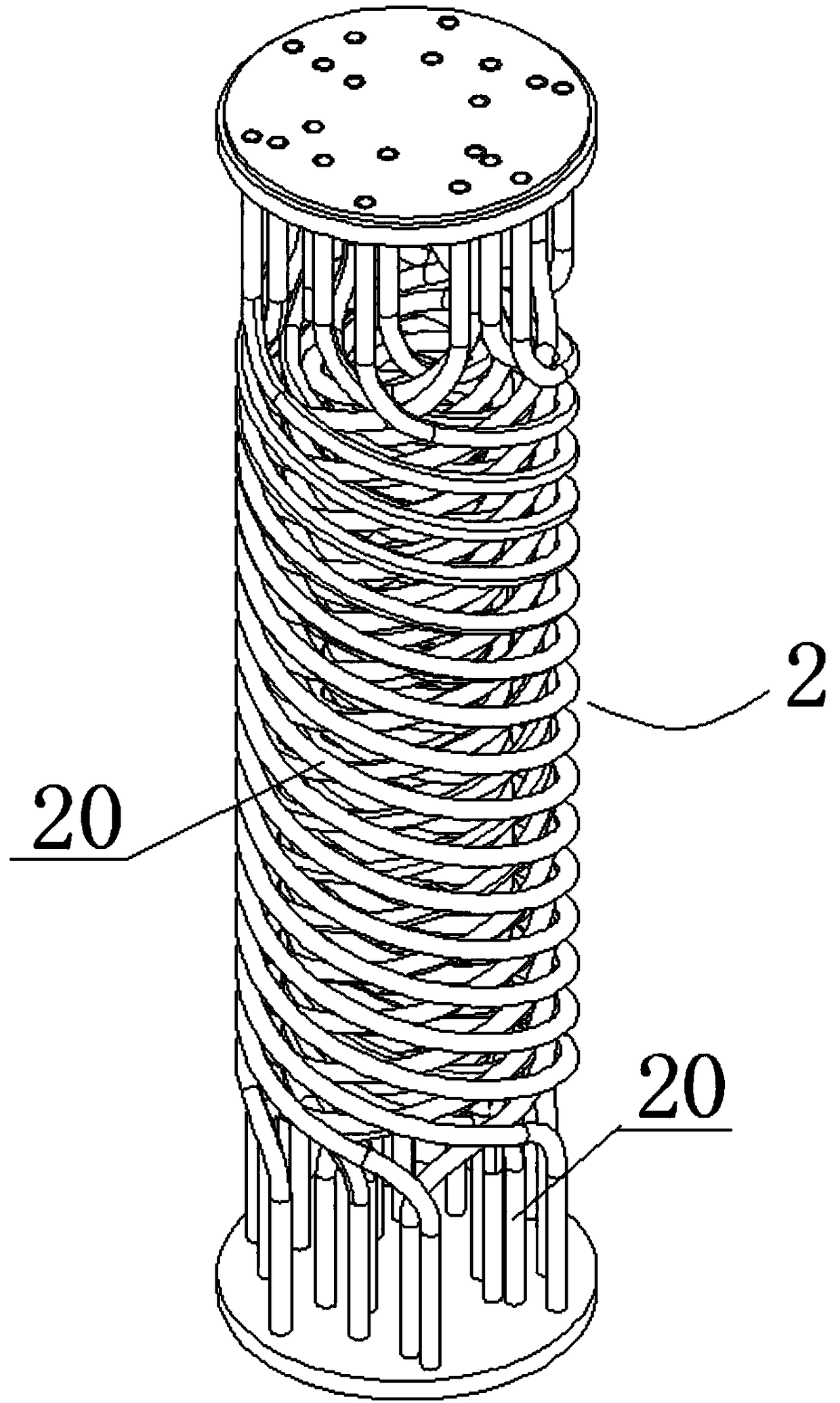

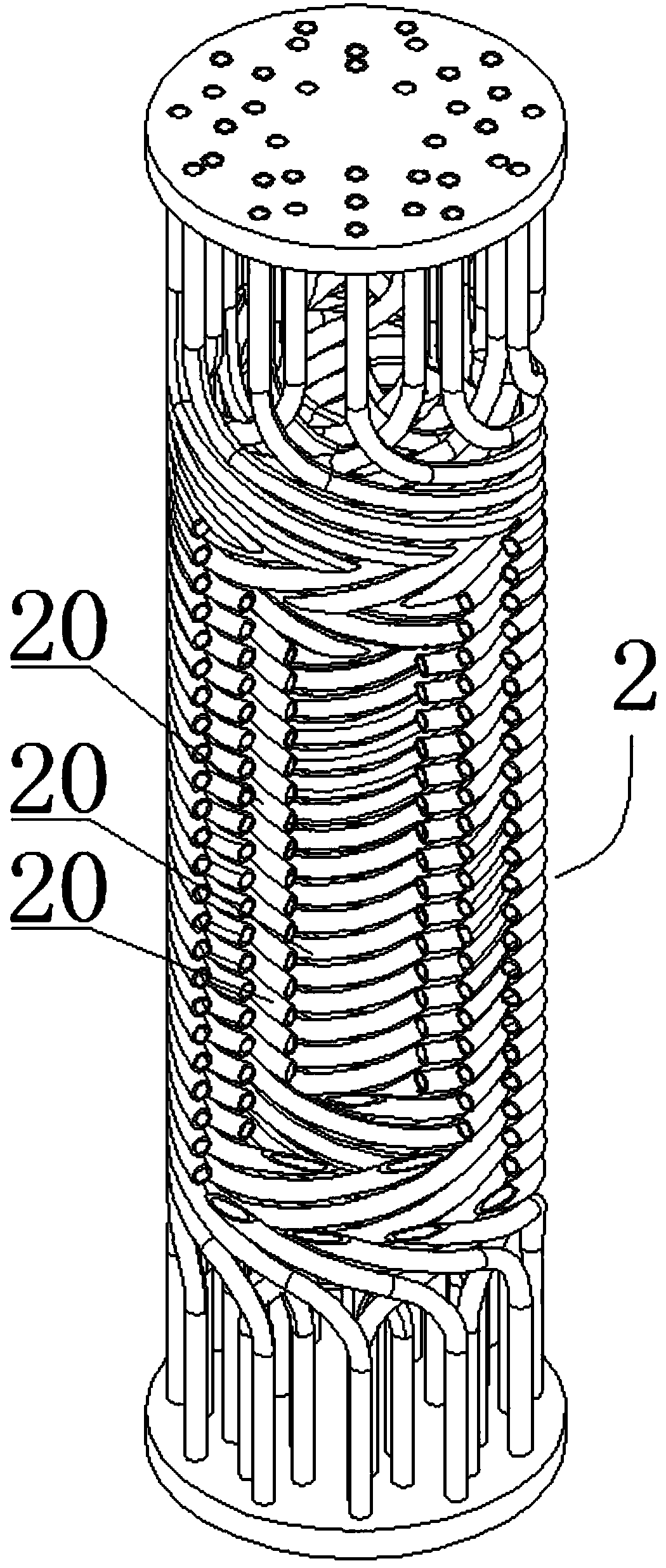

[0030] Such as Figure 1 to Figure 5 As shown, a continuous flow reactor of this embodiment is characterized in that it includes: a shell 1, the shell 1 is provided with a shell-side inlet 10 and a shell-side outlet 11 communicating with its inner cavity, the shell The shell side of 1 is used to circulate the heat transfer medium, so that the reactants in the tube side of the reaction tube 20 can maintain a suitable reaction temperature. The upper and lower ends of the shell 1 are connected with a tube plate 3 and a communication device. The interior of the reaction tube set 2 is arranged, and the reaction tube set 2 includes a plurality of reaction tubes 20, and the upper and lower ends of each reaction tube pass through and are fixedly connected to the tube plate 3, and all the reaction tubes 20 are sequentially passed through the communication device. Connected in series.

[0031] Such as Figure 4 with Figure 5 As shown, preferably, the communication device is a baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com