Recovery method of N-methyl pyrrolidone

A technology of methyl pyrrolidone and a recovery method, which is applied in the field of recovery of chemical raw materials, can solve the problems of difficult control of the rectification process, inability to apply on a large scale, low working temperature, etc., so as to eliminate the phenomenon of concentration polarization and improve the average operating temperature. , the effect of reducing pressure drop and temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

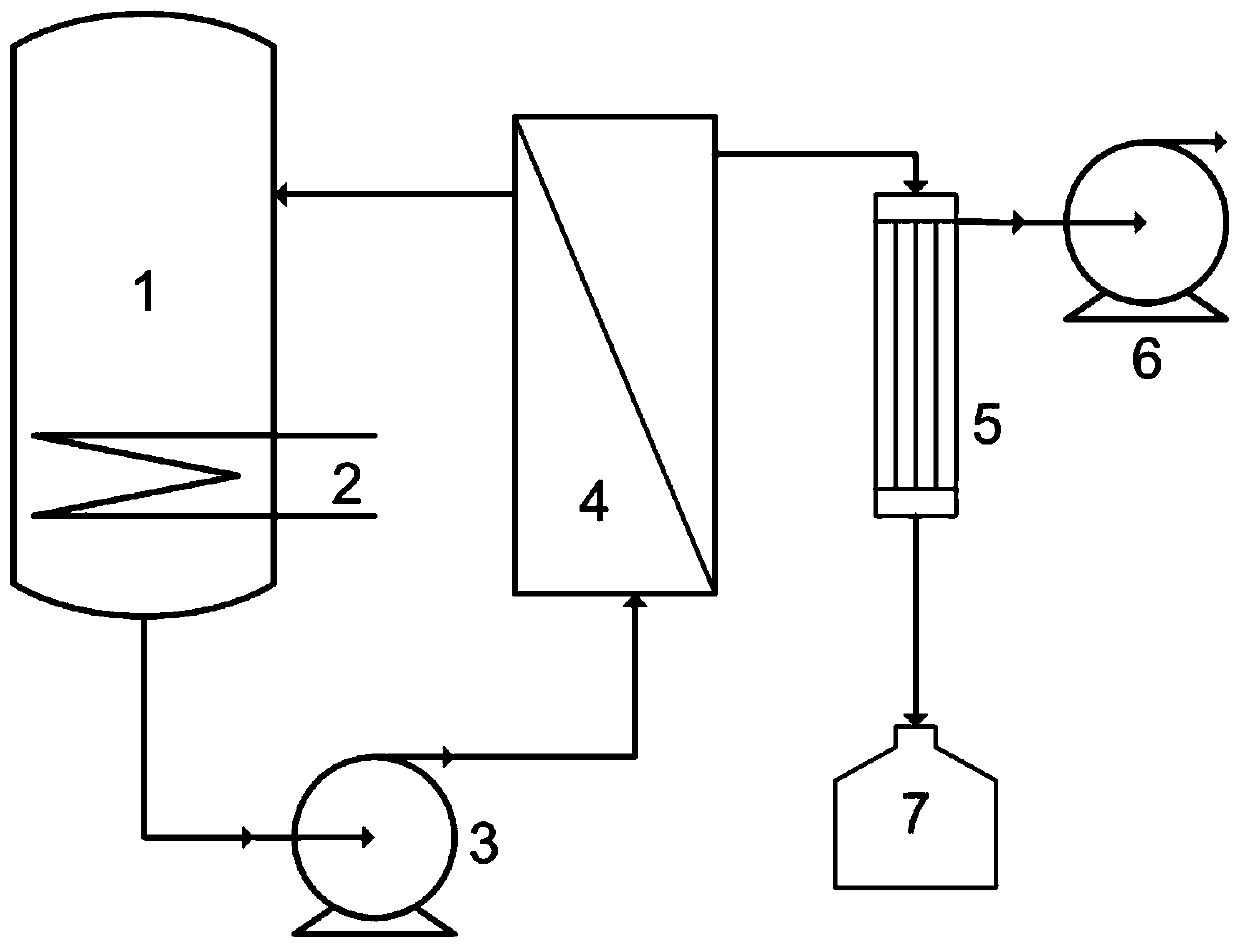

Image

Examples

Embodiment example 1

[0038] Implementation example 1. Add 500kg of water-containing 20% (mass content, the same below) NMP aqueous solution into the circulation tank, turn on the heater to start heating the feed liquid, turn on the vacuum pump to collect the permeate side, condenser and permeate of the membrane pervaporation separator The tank is gradually evacuated to an absolute pressure of 0.1kPa-15KPa, the condensation temperature is controlled at about -30°C, and the circulation temperature is 130°C. The cost of membrane module treatment and vacuum system is as follows

[0039] Permeate side pressure / kpa Membrane capacity kg / h Vacuum system cost / Kw 0.1 110 60 2 100 5 5 95 4 10 60 2 15 50 2

Embodiment example 2

[0040] Implementation Case 2: Add 500kg water containing 20% (mass content, the same below) NMP aqueous solution into the circulation tank, turn on the heater to start heating the feed liquid, turn on the vacuum pump to collect the permeate side, condenser and permeate of the membrane pervaporation separator The tank is gradually evacuated to an absolute pressure of 2KPa, the condensation temperature is controlled at about 7°C, and the circulation temperature is 70-160°C. The processing capacity of the membrane module and the qualified rate of product quality are as follows

[0041] temperature / ℃ Membrane capacity kg / h Rate of qualified products 70 50 100 (colorless) 100 65 100 (colorless) 130 100 99 (colorless yellowish) 150 183 98 (light yellow) 160 240 85 (red) 190 492 70 (dark red)

Embodiment example 3

[0042] Implementation Case 3: Add 500kg of water-containing 20% (mass content, the same below) NMP aqueous solution into the circulation tank, turn on the heater to start heating the feed liquid, turn on the vacuum pump to collect the permeate side, condenser and permeate of the membrane pervaporation separator The tank is gradually evacuated to an absolute pressure of 2KPa, the condensation temperature is controlled at about 7°C, the circulation temperature is 130°C, and the flow rate of the membrane module is adjusted. The processing capacity of the membrane module is as follows:

[0043] Velocity m / s flow m3 / h Membrane capacity 0.15 3.49 45 0.4 9.29 60 0.5 11.63 98 0.8 18.61 101 1 23.26 101 1.6 37.21 101

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com