Heat storage system and method for the charging and discharging thereof

a heat storage system and heat storage technology, applied in the field of thermal storage, can solve the problems of not solving the dilemma, the system does not offer any thermal conductivity improvement for phase change materials, any transfer speed improvement on work fluids, etc., and achieves the effect of increasing the number of reynolds and the thermal transfer coefficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072]In order to provide a better understanding of the invention, below is a description, with the help of diagrams, of the preferred embodiment of this invention.

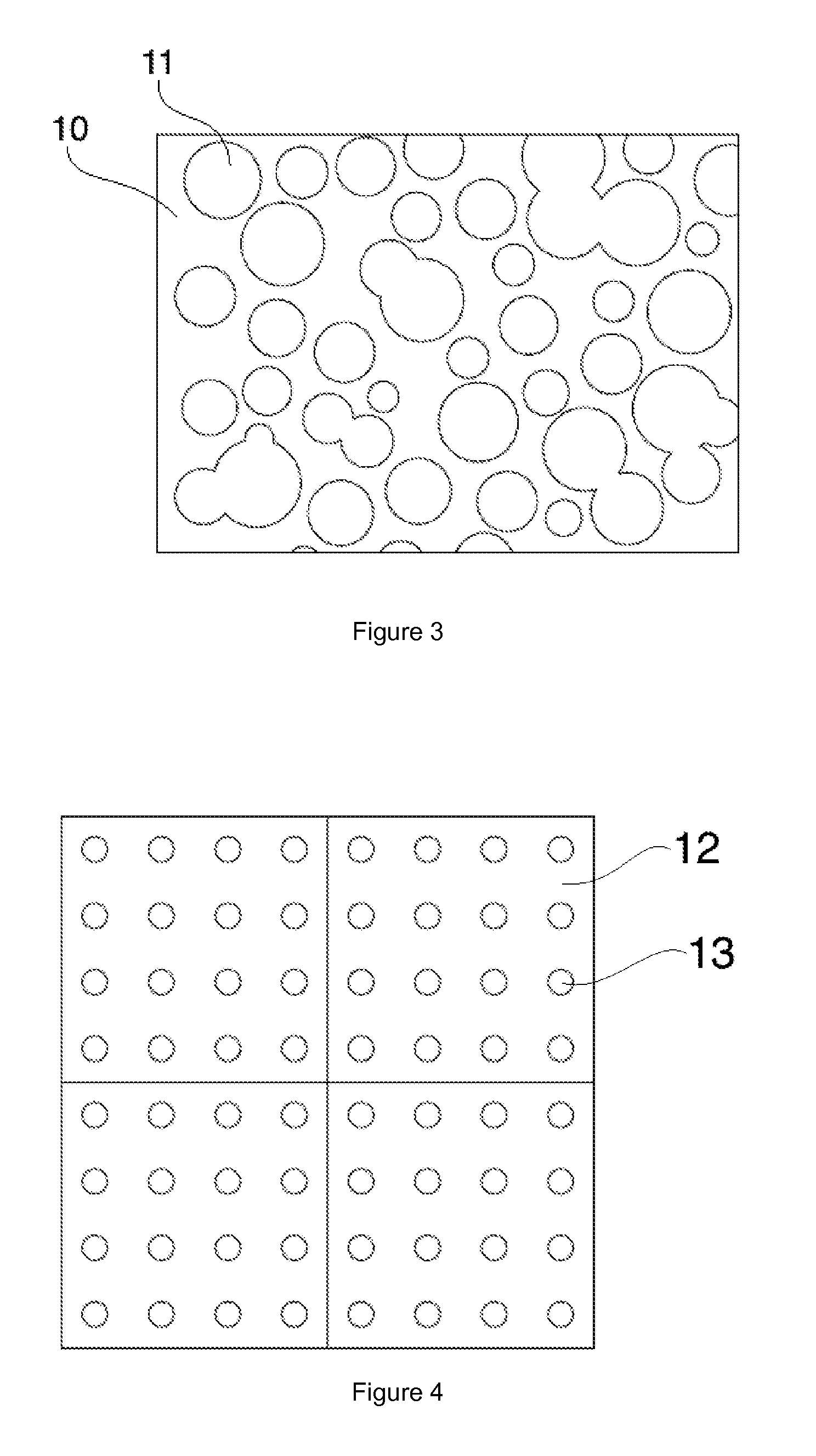

[0073]The thermal storage system of this invention comprises a composite storage material made up of a matrix (12) made of a rigid, graphite, carbon or metal foam (10) with high porosity and thermal conductivity, with said matrix being infiltrated with highly thermally energetic salts based on hydroxides (11) (see FIGS. 3 and 4). This storage material is located inside a casing or container tank.

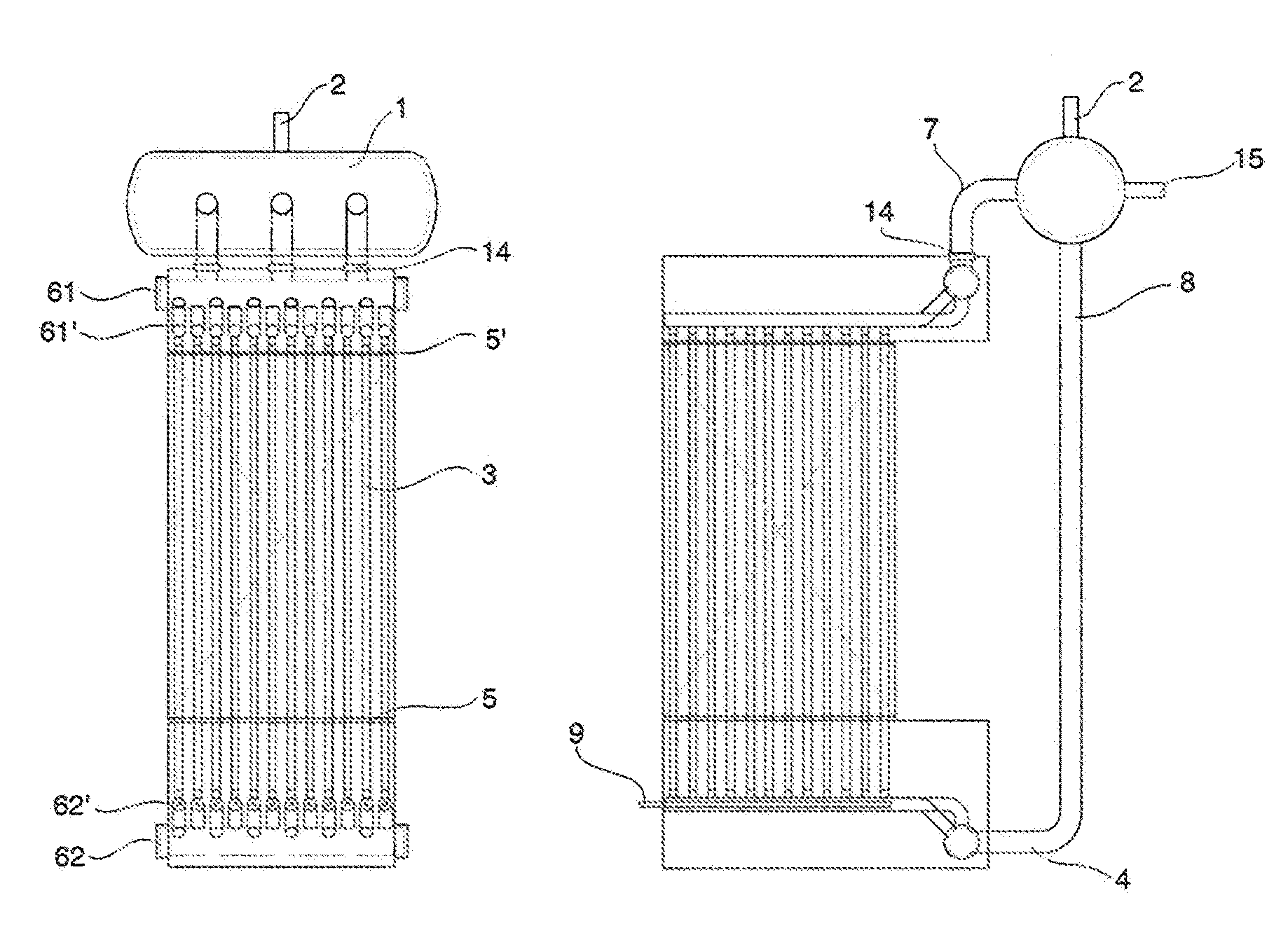

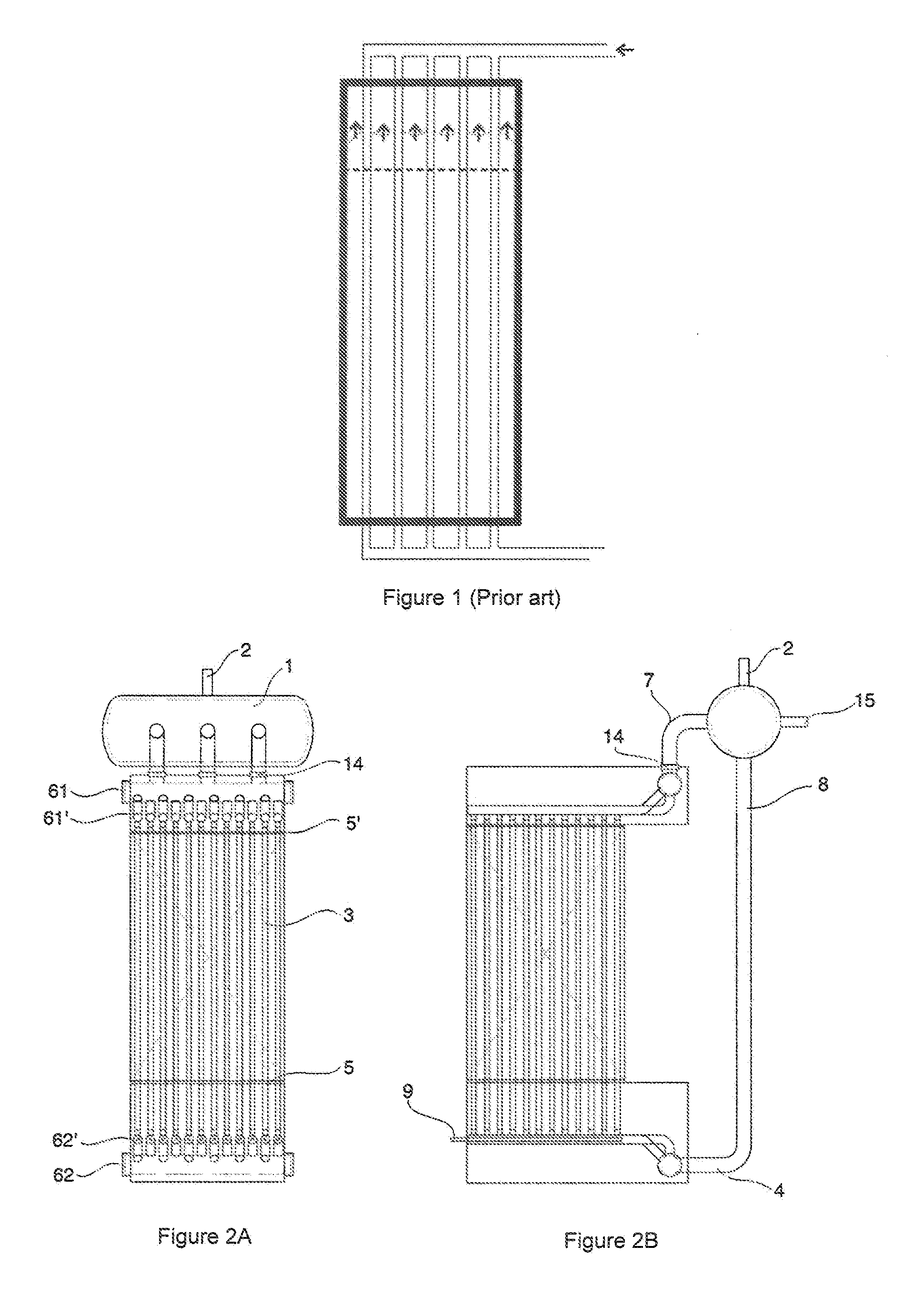

[0074]As shown in FIG. 2, the storage system also has a heat exchanger made up of heat exchanger tubes (3), preferably vertical, through which the heat-transfer fluid circulates and which pass through the storage material through tube pass-through orifices (13, FIG. 4) so there is direct contact between this storage material and the vertical tubes (3).

[0075]The salt (11) infiltrated in the matrix (12) of the storage material melts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com