High-efficiency tower solar power station heat collector system with diameter gradually varied heat absorbing tubes

A tower-type solar energy and heat-absorbing tube technology, which is applied to solar collectors, solar collectors in specific environments, and solar heating systems, can solve the difficulty of increasing the tracking control system of the heliostat field and cannot reduce the collection Heater surface overheating and other problems to achieve the effect of improving safety and stability, reducing excessive thermal stress and severe thermal expansion, reducing radiation and convective heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

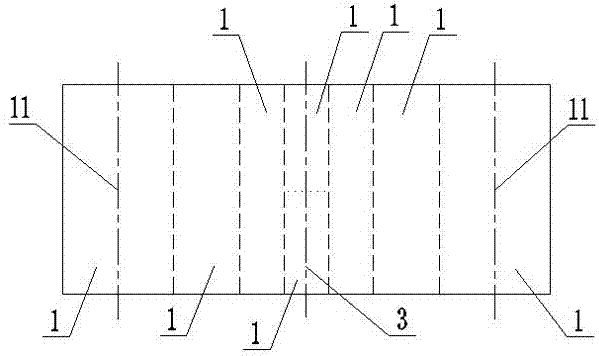

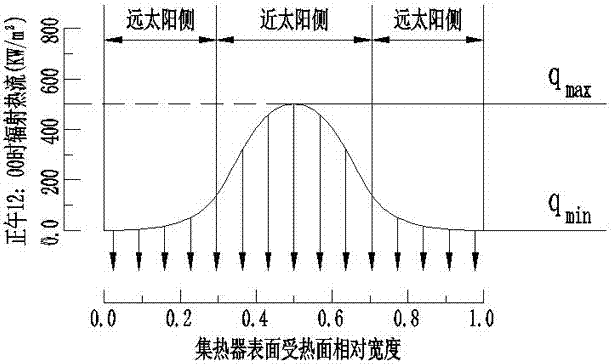

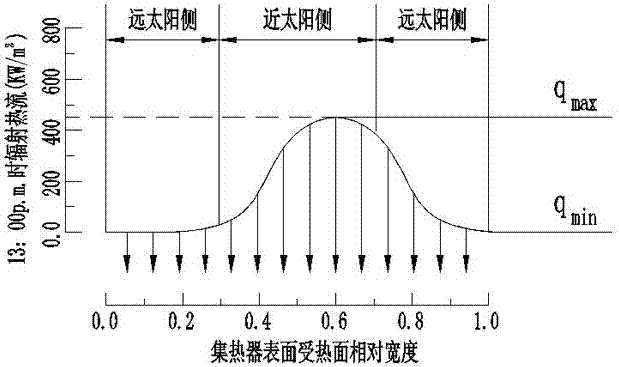

[0031] see Figure 1-Figure 7 , the tower solar thermal power generation system is essentially a centralized system, and usually the heliostat field focuses the radiation so that the radiation heat flow on the collector surface is regarded as a Gaussian distribution or a cosine distribution. special, such as figure 2 As shown, at 12:00 noon, the radiation heat flux on the collector surface is symmetrically distributed, and the symmetry axis can be taken as the maximum value of the solar radiation heat flux on the collector surface q max The straight line or the minimum value of solar radiation heat flux q min The straight line where, in the present invention, the axis of symmetry 3 takes the maximum value q of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com