Preparation method of interpenetrating network structure p(liamps)-based single ion transport gel polymer electrolyte film

An interpenetrating network structure, gel polymer technology, applied in structural parts, circuits, electrical components, etc., can solve the problems of poor dimensional stability, low ion migration number, etc., achieve good thermal stability, improve migration number, and improve The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

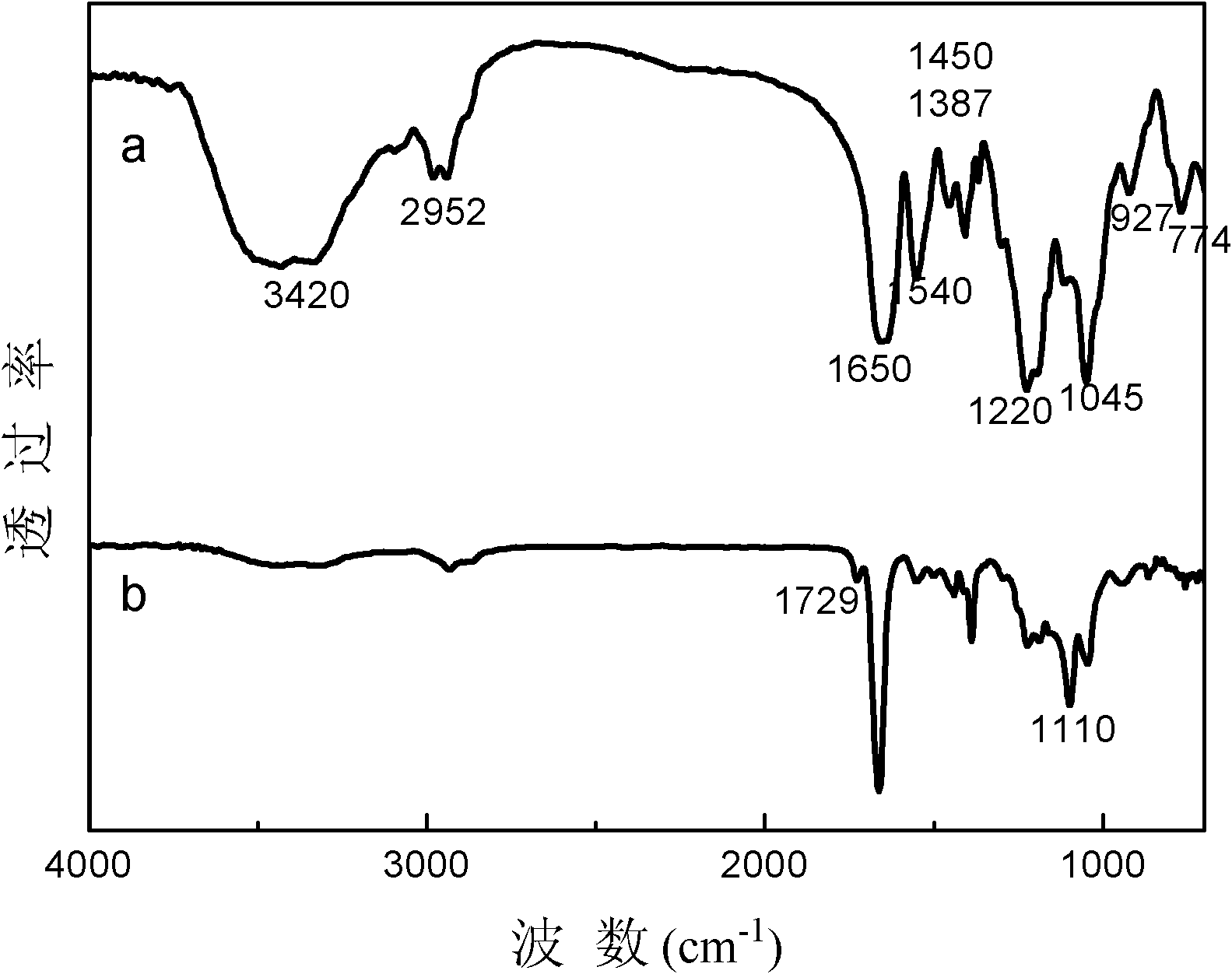

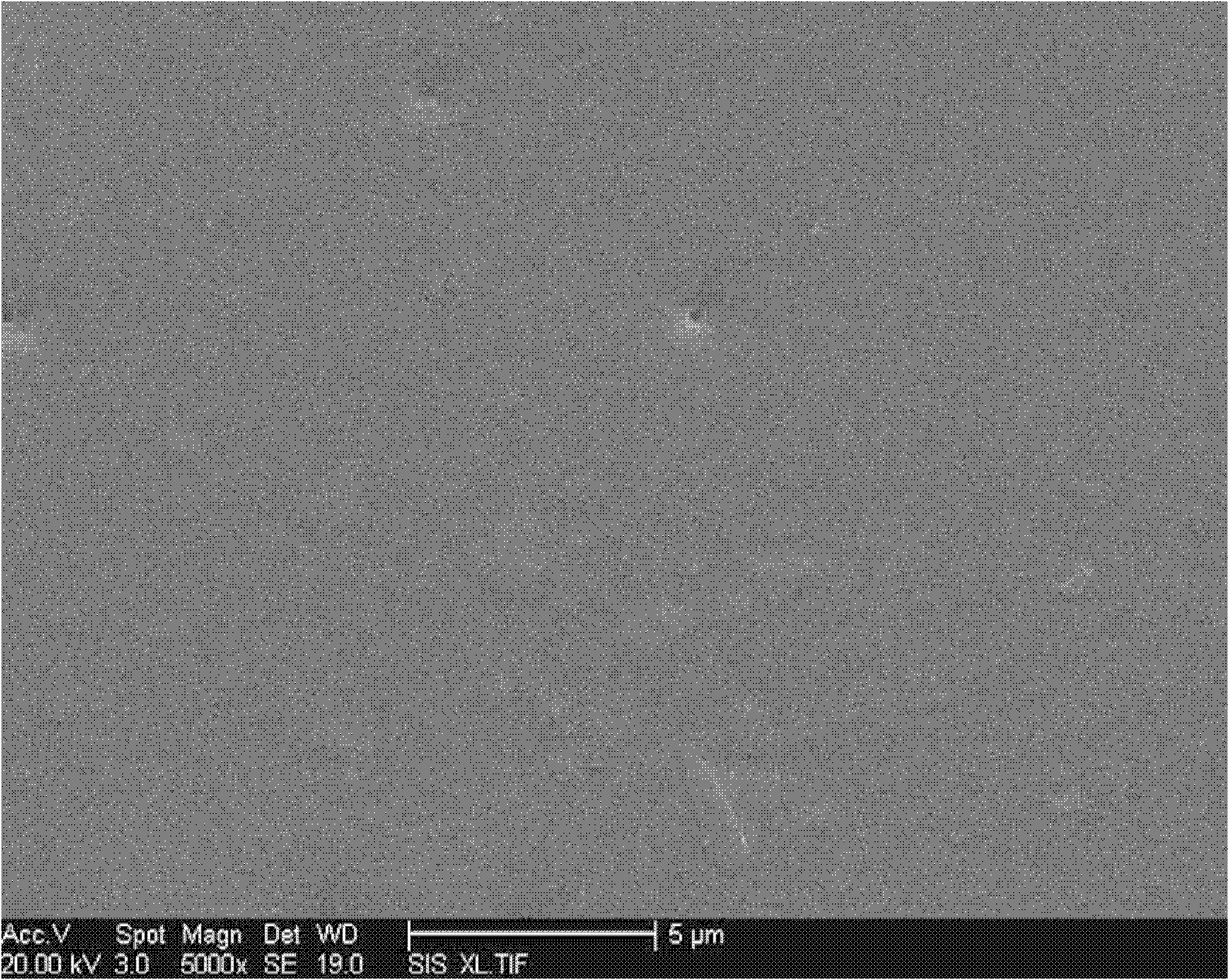

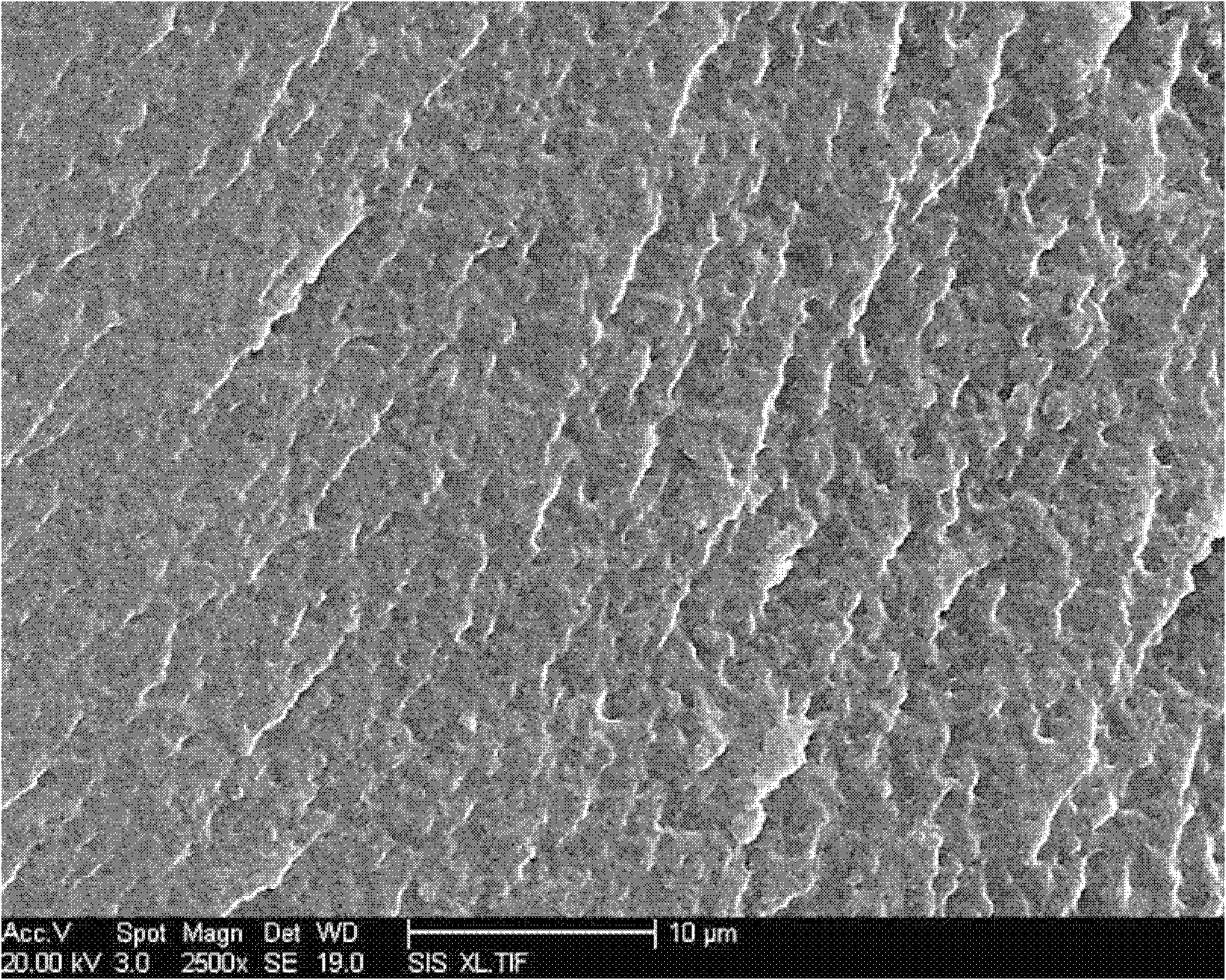

[0010] Embodiment 1: In this embodiment, the preparation method of interpenetrating network structure P (LiAMPS)-based single-ion transport gel polymer electrolyte film is carried out according to the following steps:

[0011] 1. Add 2-acrylamide-2-methylpropanesulfonic acid (AMPS) to N,N-dimethylformamide (DMF) to make 2-acrylamide-2-methyl with a mass concentration of 30%. N,N-dimethylformamide solution of propanesulfonic acid, then slowly add lithium carbonate (Li 2 CO 3 ), adding Lithium Carbonate needs 30~40min, stirring 2h, wherein the mol ratio of 2-acrylamide-2-methylpropanesulfonic acid and lithium carbonate is 2: 1, obtains the DMF solution of LiAMPS monomer;

[0012] Two, then add vinyltriethoxysilane (VTES for short) to the DMF solution of LiAMPS monomer obtained in step 1, the mole of vinyltriethoxysilane and 2-acrylamide-2-methylpropanesulfonic acid The ratio is 1:1, then add azobisisobutyronitrile (abbreviated as AIBN, as initiator), the amount of azobisisobut...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment is different from Embodiment 1 in that: the temperature of the polymerization reaction in step 2 is 75°C. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the DMF solution of copolymer P (LiAMPS-co-VTES) described in step 3 and polyethylene glycol dimethacrylate (PEGDMA ) in a weight ratio of 1:2. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com