Device for treating refractory wastewater through electrocatalytic oxidation and method

A technology of electrocatalytic oxidation and treatment device, applied in special compound water treatment, water/sewage treatment, water treatment parameter control, etc. Effects of concentration polarization and mass transfer problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings.

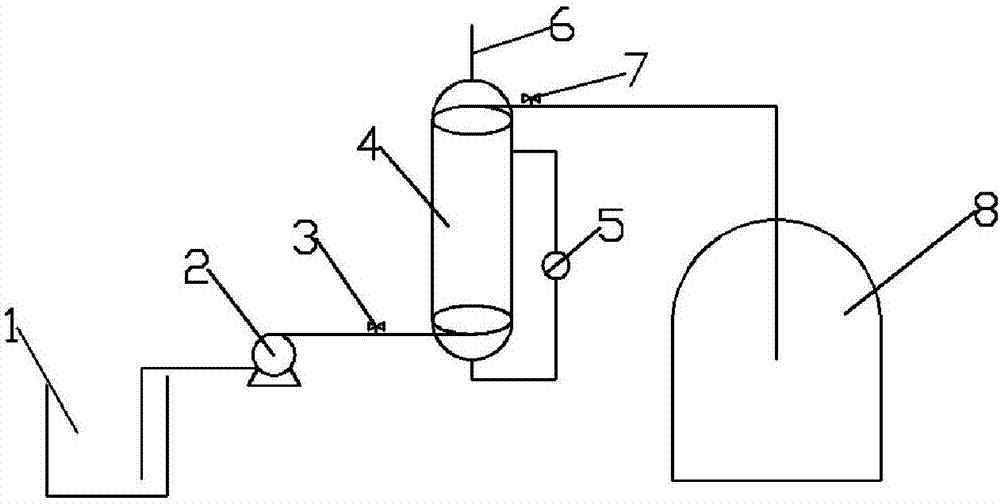

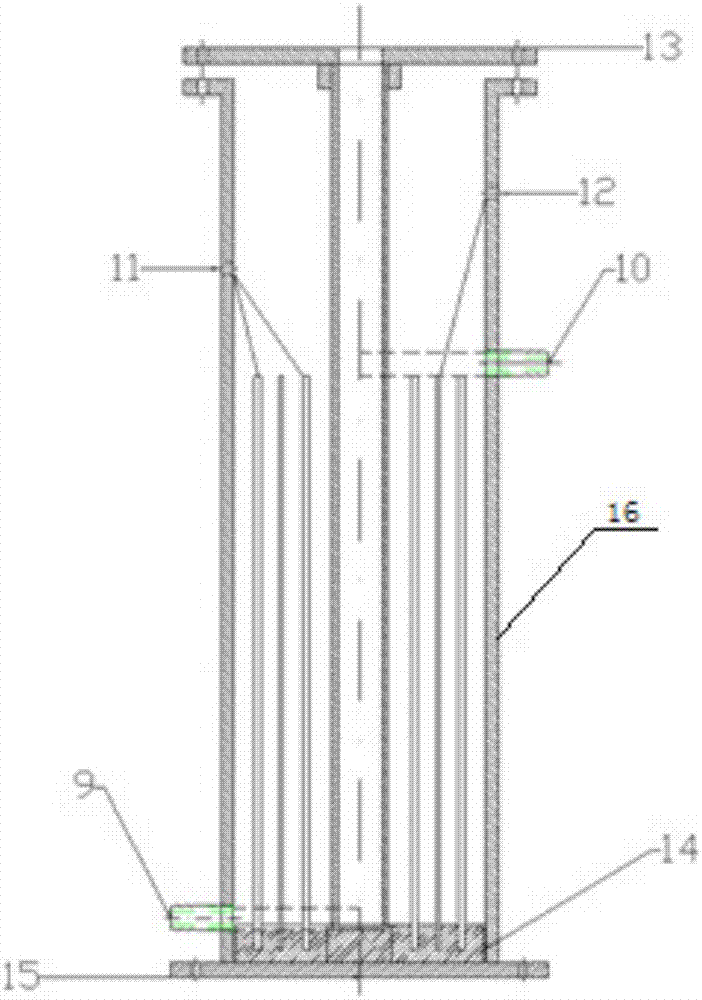

[0023] See figure 1 , 2. The device of the present invention includes a wastewater conditioning tank 1, the outlet of the wastewater conditioning tank 1 is equipped with a corrosion-resistant magnetic pump 2, and the outlet of the corrosion-resistant magnetic pump 2 is connected to the inlet of the electrocatalytic system 4 through a pipe 3 with a valve, The outlet of the electrocatalytic system 4 is connected to the effluent storage tank 8 through a pipe 7 with a valve. The electrocatalytic system 4 includes a housing 16 with an internal wastewater circulation pipe 5 and upper covers arranged on the upper and lower ends of the housing 16. 13 and the base 15, the upper cover 13 is provided with an exhaust gas outlet 6, and an electrode base 14 with a slot is installed on the base 15 in the housing 16. The slot of the electrode base 14 is equally spaced from the center of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com