Rotational flow electrolyzing device for separating and recycling metal composite waste material

A technology of metal compounding, separation and recovery, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of environmental pollution, high acid consumption, etc., to improve electrolysis efficiency, reduce energy and acid consumption, low-cost separation and recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

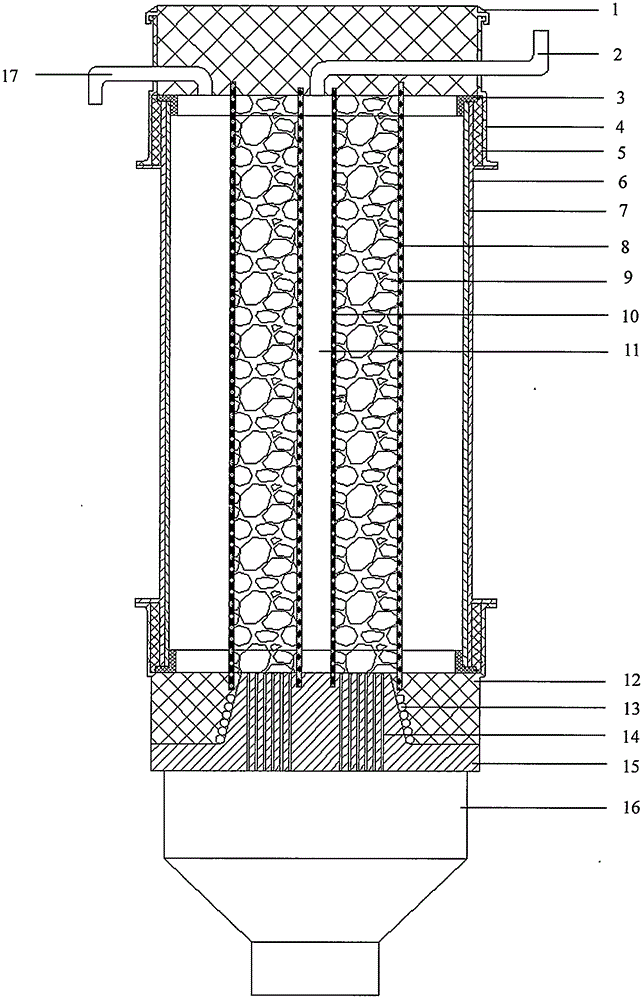

[0024] Such as figure 1 As shown, it is a structural schematic diagram of a swirling flow electrolysis device in a preferred embodiment of the present invention, which includes an upper end cover 1, a liquid inlet 2, a cathode fixing plate 3, an upper connector 4, a sealing block 5, an outer tank body 6, and a cathode 7. Anode basket 9, anode basket wall 8 (wall of anode basket 9), liquid inlet channel 11, liquid inlet channel wall 10 (wall of liquid inlet channel 11), lower connector 12, sealing ring 13, anode slime channel 14 , connect positive electrode copper 15, anode slime collection tank 16, liquid outlet 17. The anode basket 9 is filled with metal composite waste and the whole is used as an anode; the upper end cover 1 is a solid body, and the electrolyte channels are opened inside to connect with the liquid inlet 2 and the liquid outlet 17 respectively, and the upper end cover 1 is connected to the outer tank body through the upper connector 4 6 connected, there is a...

Embodiment 2

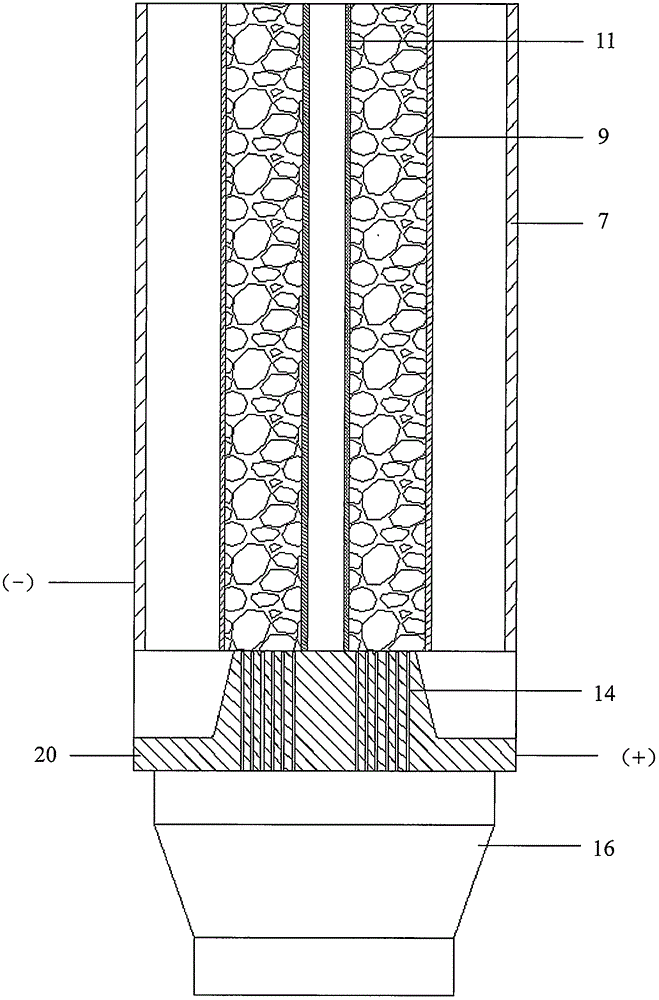

[0046] Such as figure 2 As shown, it is a schematic structural diagram of an embodiment of a cyclone electrolysis device for separating and recycling metal composite waste according to the present invention. The device includes: cathode 7, anode basket 9, liquid inlet channel 11, anode slime channel 14, anode slime collection tank 16, Power supply 20, wherein: an anode basket 9 is arranged in the cathode 7 and there is a gap between the two, metal composite waste is loaded into the anode basket 9 and the whole is used as an anode, a liquid inlet channel 11 is provided in the anode basket 9, and an anode basket 9 is provided below There is an anode slime channel 14, the anode slime channel 14 is connected to the anode slime collection tank 16, and the power supply 20 supplies power for the whole device; the anode slime channel 14 is connected to the anode slime collection tank 16; the electrolyte flows through the liquid inlet channel 11 to the metal compound outside the channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com